Updates: my engine has over 230k and on it and was producing quite a bit of blow-by. So I decided to tear it down and rebuild it with:

New bearings

New rings

100% new OEM gaskets

Pressure tested head

Everything was in great shape. The block just needed a hone and all the bearing surfaces were great. The engine was surprisingly simple and easy to rebuild.

Measuring piston projection:

I went big and got the FSM-specified Loctite 534 for the front housing:

Engine put back together:

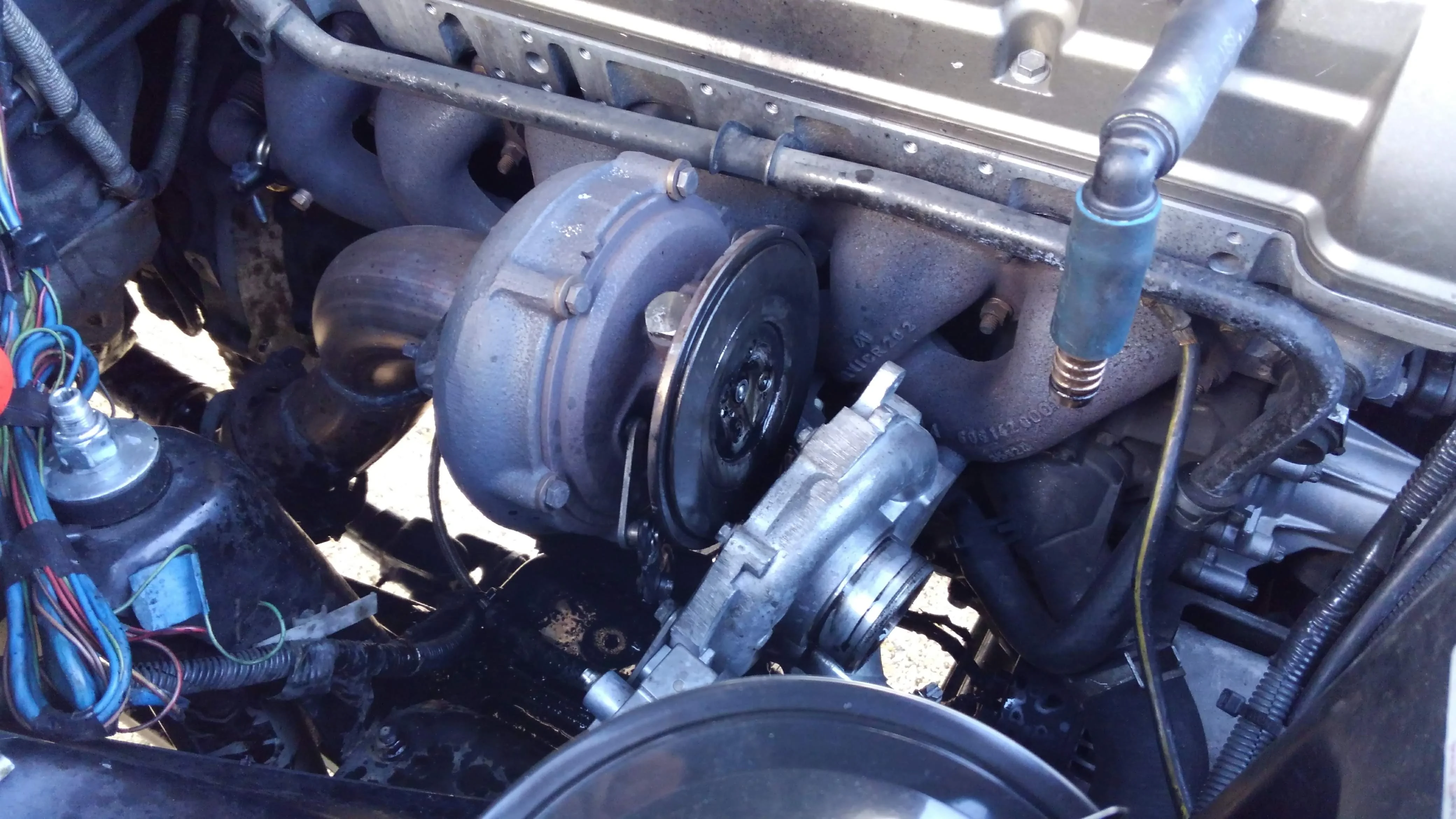

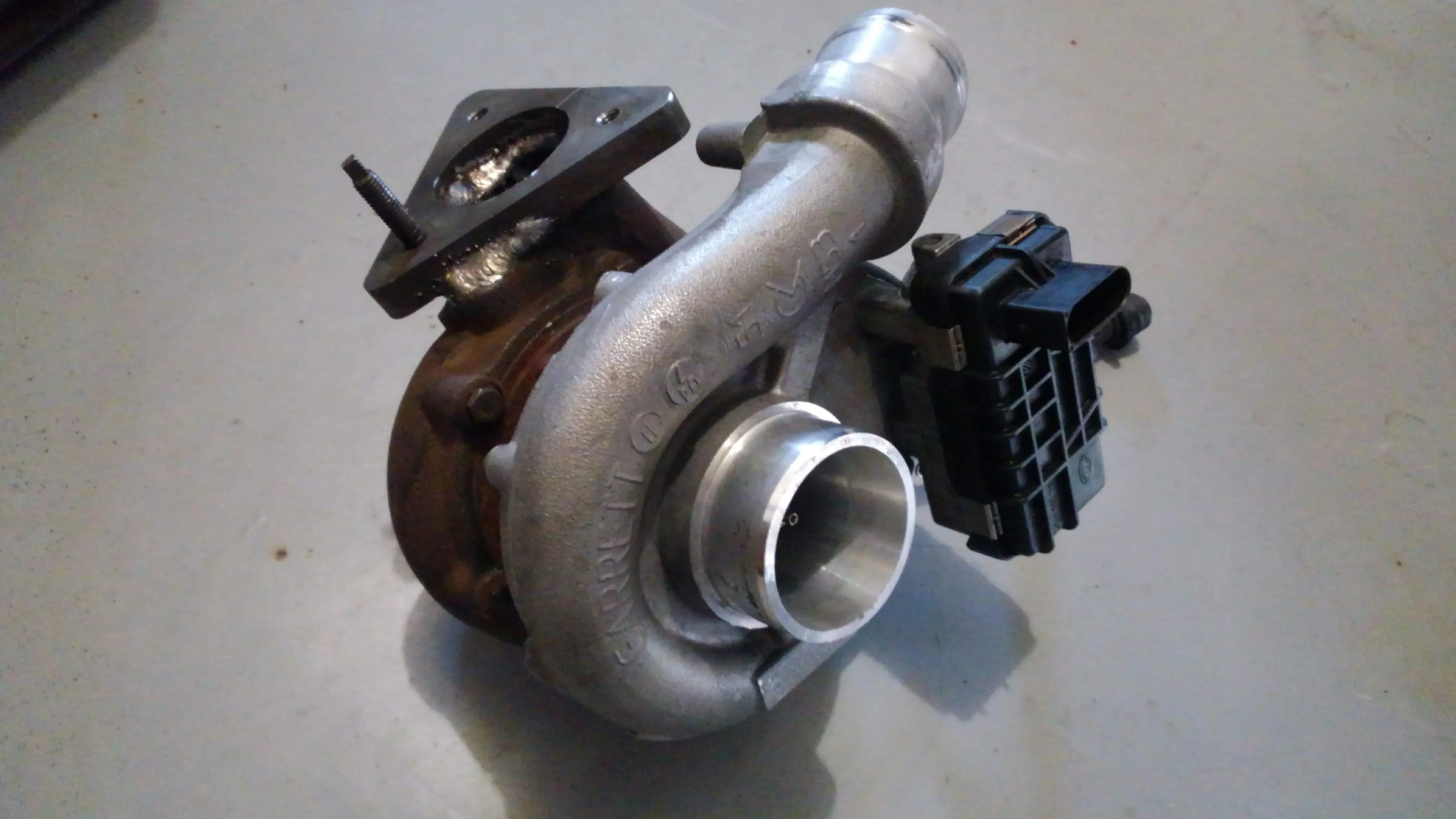

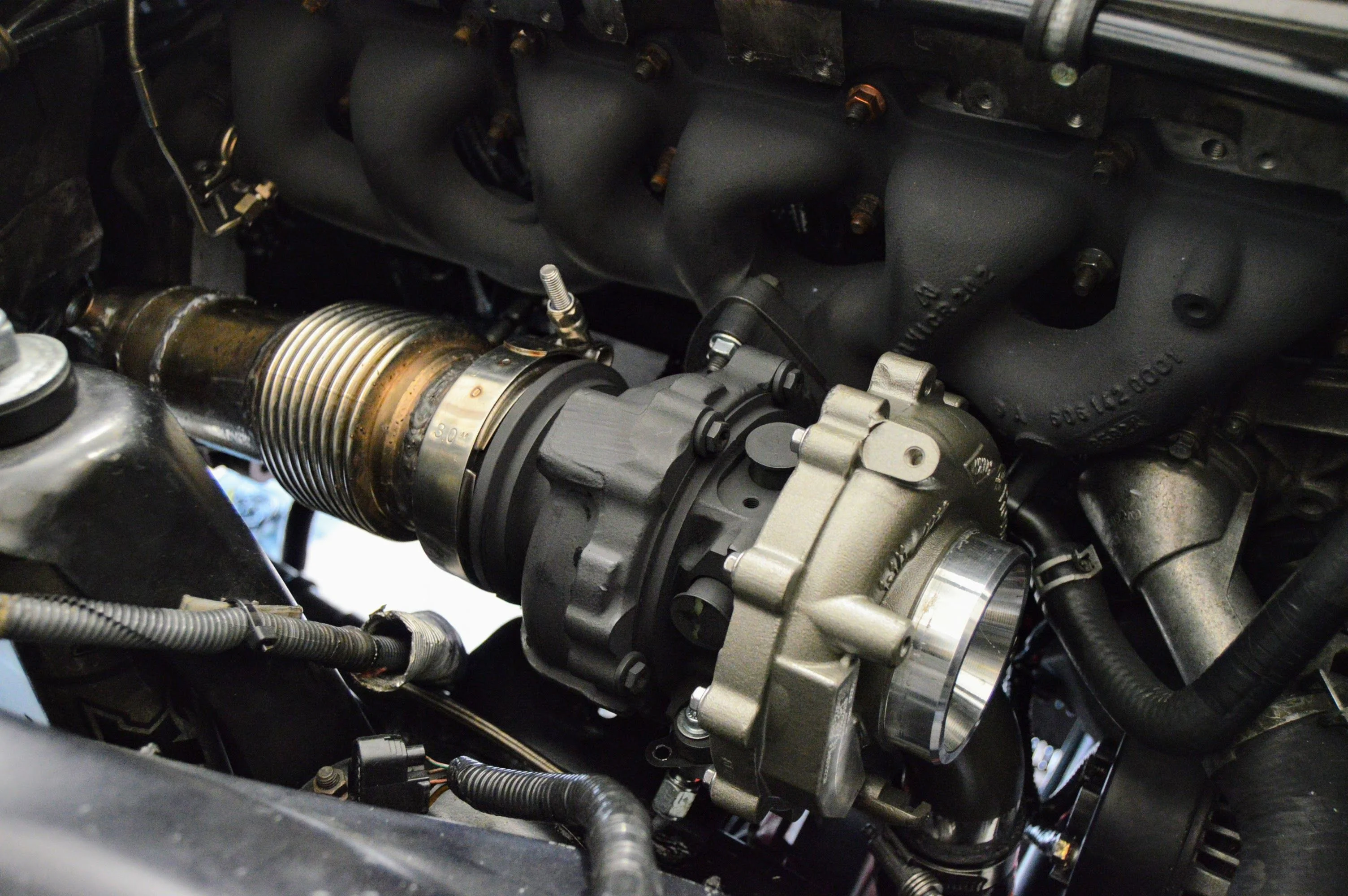

I decide the 2-stage system had too much potential for "German car problems" so I snagged a GTD2060VZ from Ebay Lithuainia and modded it to fit.

This is a 5th-gen Honeywell VNT system so it's much better in every way than the old GTA2359.

I drove 50 miles, changed the oil, then 500 miles and changed the oil again. Fired right up with zero leaks and problems and I was back in the mountains in no time.

First gear is still not as snappy as I'd like. I realized, though, that the truck is on 35's with stock gearing at high elevation. So the easy solution is just to regear like everyone does anyway.

Turns out that 2nd gear in low range is pretty close to how 1st gear with 5.29's would feel. So I drove around like that and liked how it felt. Ordered parts and will be installing in the coming weeks.