i think adding the filter did the trick and some correct weight oil should improve things even more. never mind the yellow murky oil; must of got a bit of water in there when cleaning with the waterspit; rocker cover was just sitting loose on its old brittle gasket. have cleaned the rockers and pushrod gallery as best i can with kero and compressed air and have resolved to pull the sump for a clean and looksee.

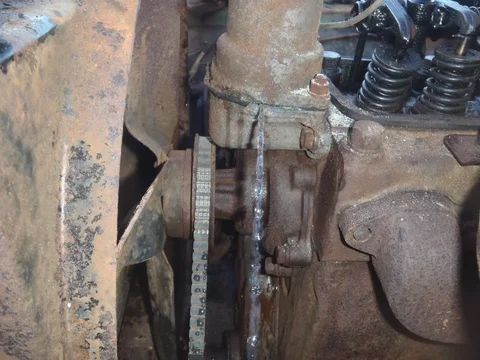

managed to play a few hours over the last couple nights. did a car shuffle. stablemate is now front center (awaiting head gasket and sump clean) and shorty is tucked in the back corner where i can tinker at will. looks so much better in a shed on a concrete floor! have pulled the driveshafts, cooling system, a few other oddments and sprayed lots more lube. threw a bit of heat at the seat bolts, battery tray and a few hydraulic fittings etc and left said pieces to ponder their folly. i like to heat and let cool a few times before applying a spanner.

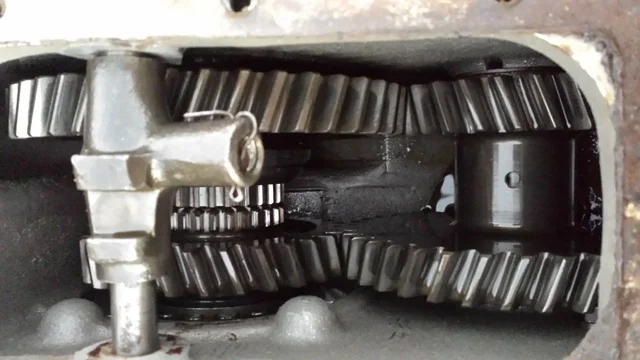

box out is next thing. this box has issues so.... (purist as i am) i think my plan is to use a later stick shift 3 speed in the shorty, at least in the short term. on the backburner i have a nice 62 fj45 i inherited in bits. it has a beautiful cab, a rough but repairable chassis and another early box with issues including a broken transfer case and lost linkages. hoping in time to build one nice box from the 2 and do a better restoration on the rust free 62 fj45.

donor stick shift will be from a 63/64 so my question is this. what issues am i going to have using a later box? will the existing shafts mate up lengthwise or am i going to have to fabricate something? (the original 61 shafts will be stowed safely unharmed) and will the donor 45 trans cover bolt up to the 61 shorty tub?

thanks for any thoughts; and i'm still having fun!