I have a 1993 with death wobble that I've tried to fix and it's still not fully gone. I'm sure there are many things I could blindly try if I had infinite money, but how can I figure out which one is actually likely to fix the issue?

I know this is a bit long, so to encourage responses: I'd be excited to send $50 to whomever first describes a diagnostic procedure which leads to diagnosing an issue that, when fixed, solves the problem. Just throwing out things it could be doesn't count unless accompanied by some test I can perform to confirm or deny whether that thing is actually the main problem before spending money and time addressing it.

When it started

I'm completely new to Land Cruisers and vehicle maintenance in general. I bought this LC in March with 163k miles and I've been baselining it ever since, so I've put less than 1k miles on it. I thought I had the minimum set of stuff done in September so I took it to an offroad picnic about an hour away by paved roads. Just before hitting dirt, I got my first death wobble around 30 mph. I thought "that was crazy", but the pavement was a little rough and I hadn't heard about death wobble before, so I did a bit of light offroading then started home. A fire forced me to take (paved) back roads for 23 miles and I got probably 8 or 9 wobbles. By the end, I was trying to intentionally trigger them to figure out what the trigger was, and I was trying various things to mitigate them instead of just braking hard, but I couldn't find any reliable patterns.

Behavior

The wobbles always started between ~20 and ~55 mph -- I took it carefully on the freeway on the way home after the wobbles on the back roads and got zero wobbles on 28 miles of freeway, then one more wobble on the 1.5 miles between the freeway and my house. The wobbles seem to be more likely to happen while on a slight curve (especially when the curve direction changes), when hitting small bumps (but larger bumps don't seem to do it), and when slightly braking, but even a combination of all these factors doesn't guarantee a wobble, and not all factors are necessary to produce a wobble. Again, I could never figure out when they would or wouldn't happen.

Initial investigation

When I got home, I found the jam nut of my front adjustable panhard rod completely disengaged, so I tightened that jam nut. I could grab the drag link or tie rod and rotate them on their axis by hand fairly easily, but I didn't feel any play. I jacked up each front wheel one at a time and tried to wiggle the wheel while grabbing at 12 and 6 and I didn't feel any play. I tried to wiggle while grabbing at 3 and 9 and did turn the wheels a bit, but didn't notice any play. I took off the mud guard of the driver front wheel and looked at the frame and panhard tower around the steering box and didn't see any cracks. I measured 30.15 PSI in front passenger tire and 30.65 PSI in front driver tire, and both wheels still had balancing weights attached (though I can't rule out some falling off). The two of four knuckle nuts I could easily access with my torque wrench were still torqued to at least 71 ft-lbs and the other two were "tight" (both sides).

After tightening the panhard jam nut, I took it back out on a 45mph street and got 2 more wobbles within 3 miles. A member of my offroad club diagnosed needing new rod ends.

Attempted fixes

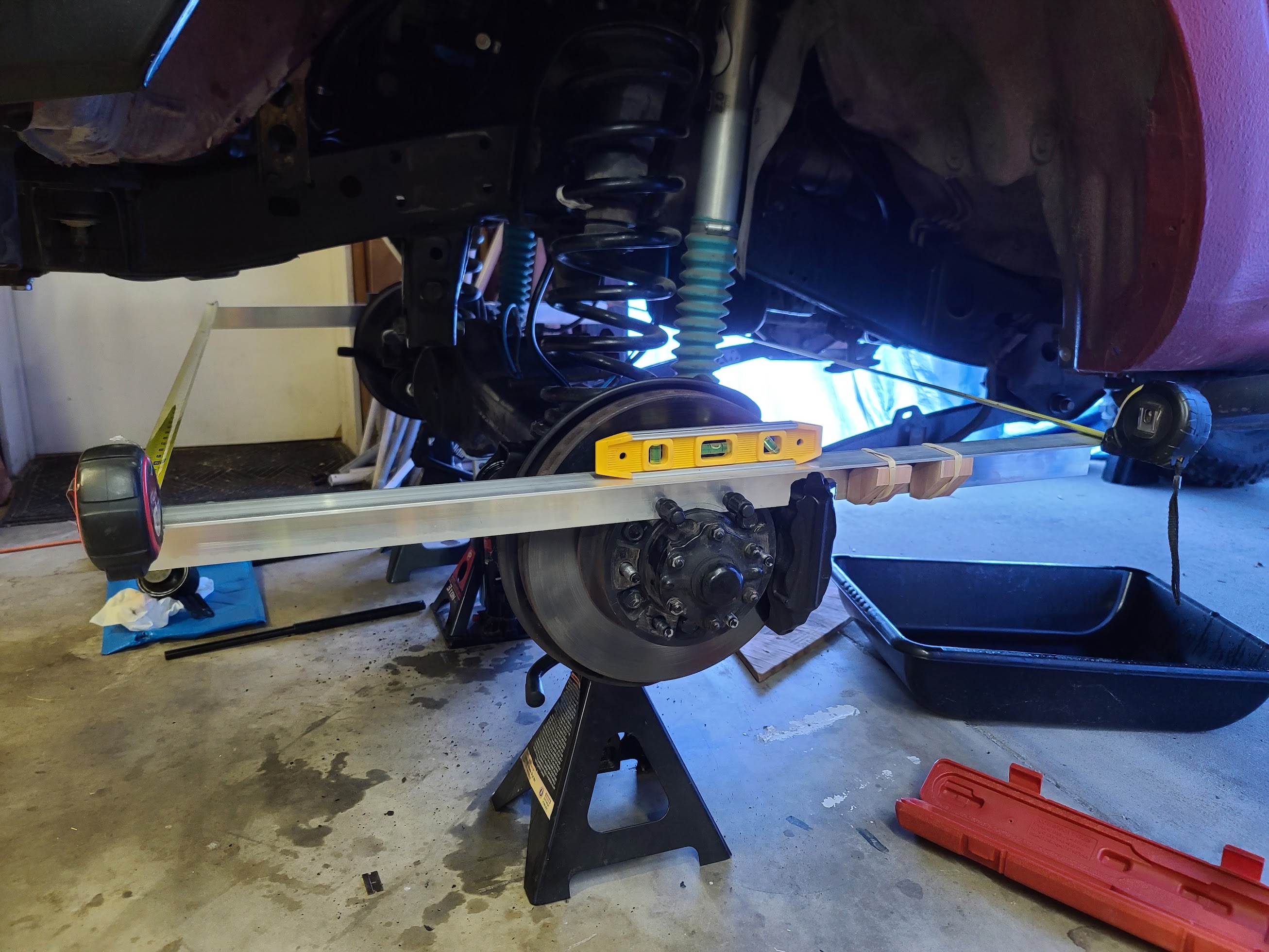

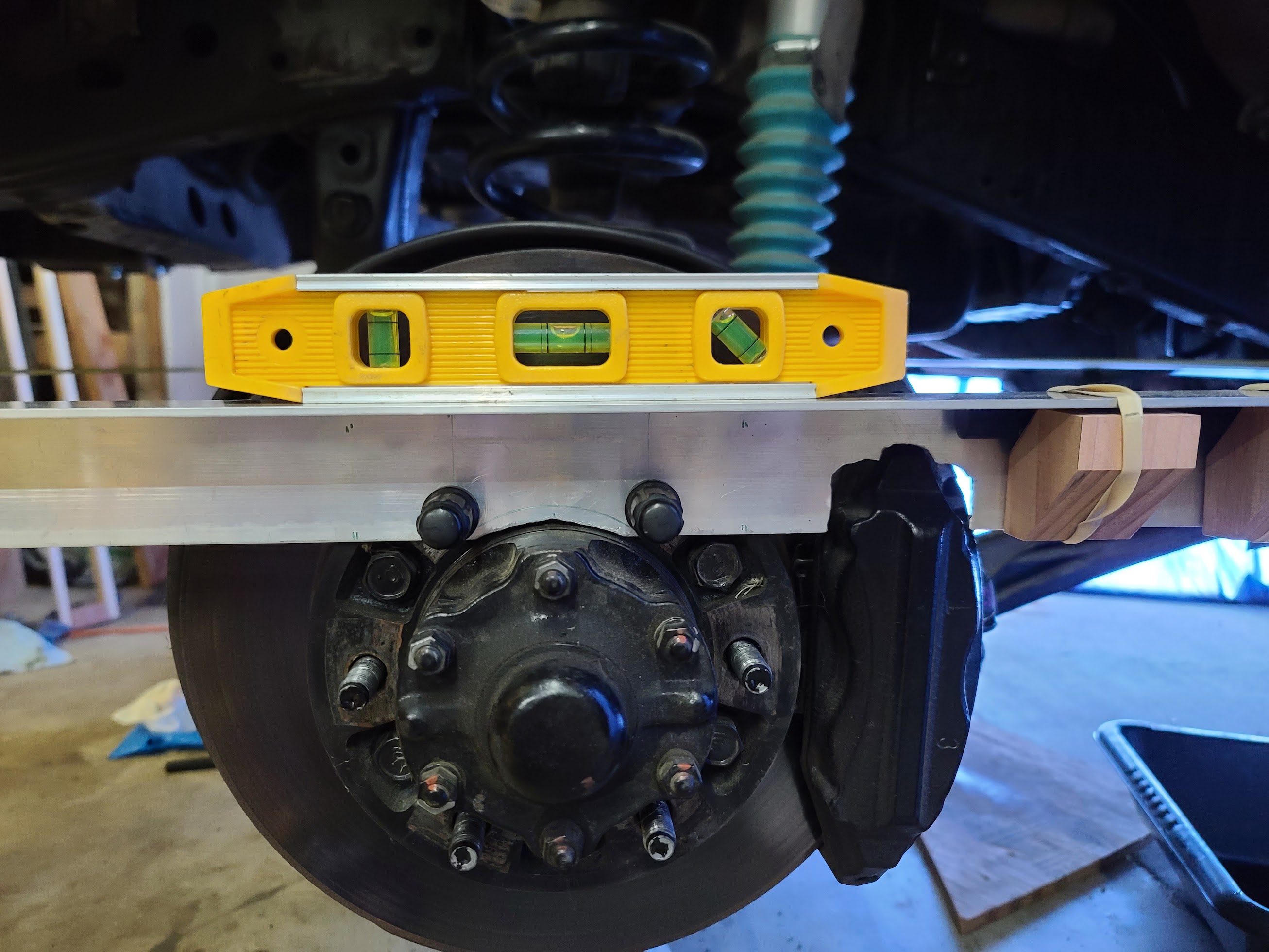

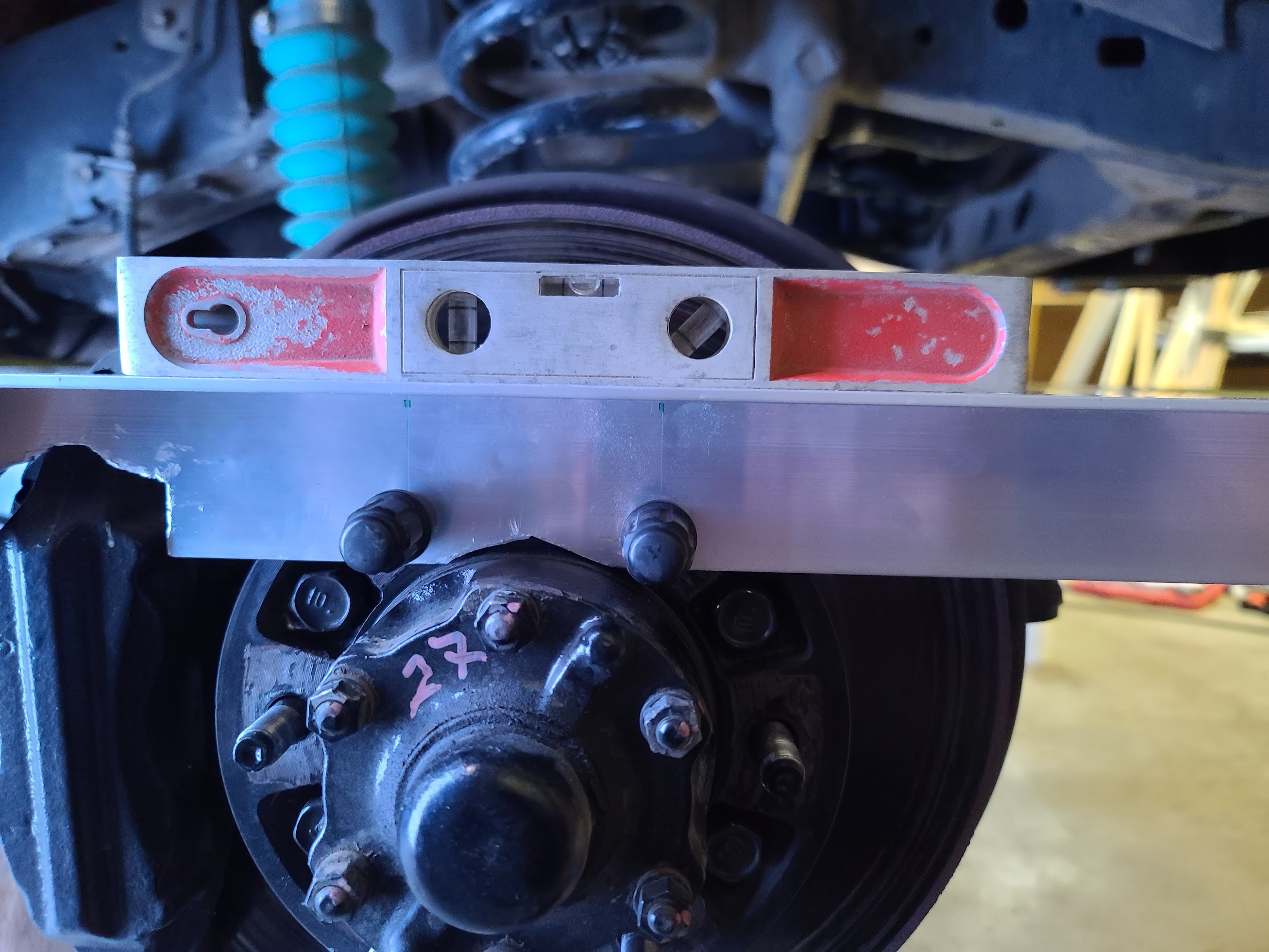

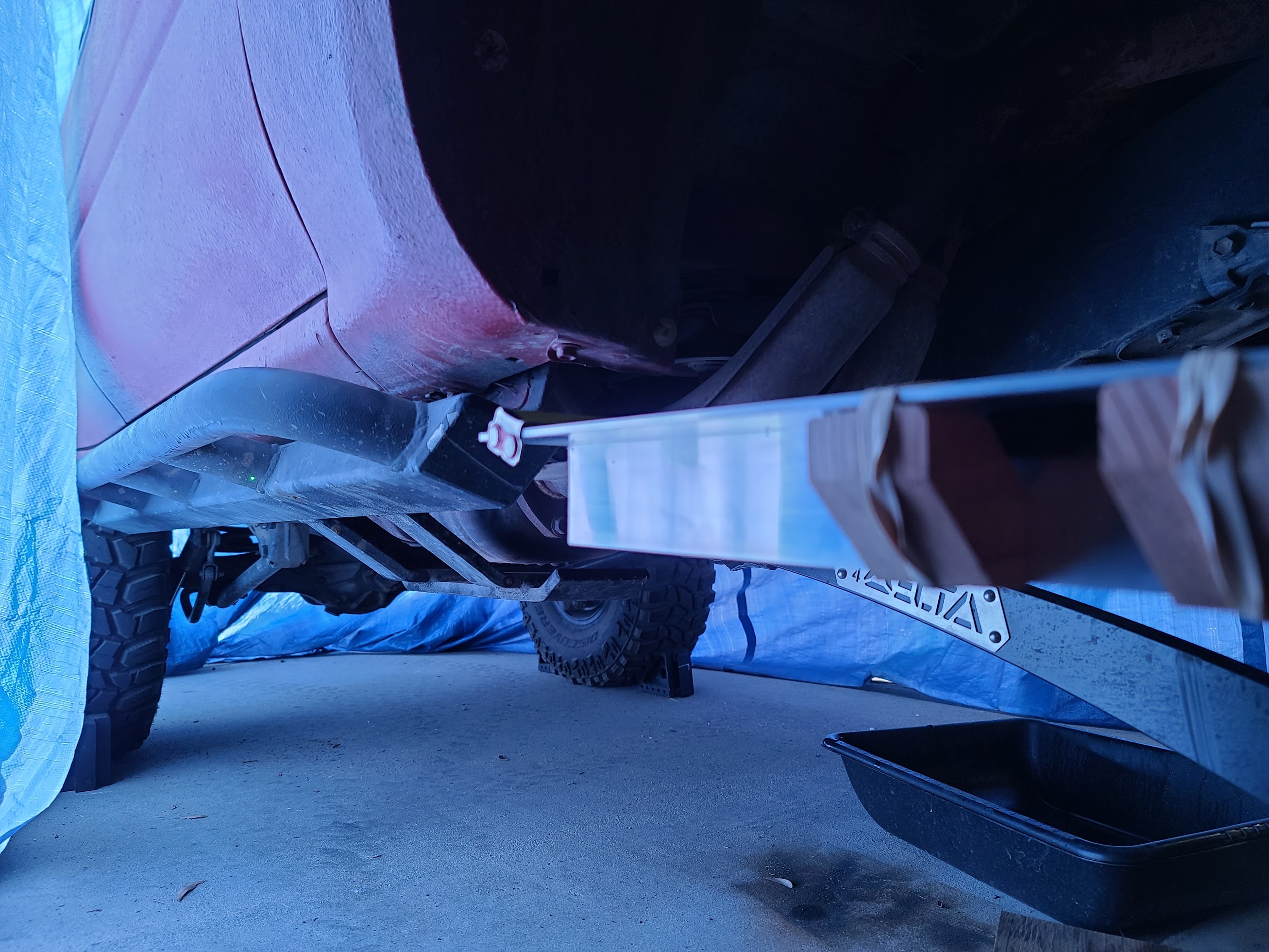

I bought the Trail Gear Heavy Duty Steering Kit which includes a new drag link, tie rod, 4 rod ends, and a steering damper. I took off both rods, damper, and the steering box and had the steering box professionally rebuilt. The old steering damper was pretty much entirely done -- spring only, virtually no oil resistance. When reinstalling the steering box, I replaced the high pressure hose with Gates and the low pressure hoses with Gates from phhkit.com. I installed the new tie rod and used two aluminum angles to set 1/8" toe in at 37" wheel diameter, using two laser pointers to center the steering:

I installed the new drag link and tried to center the steering wheel as closely as possible using the two laser pointers on my alignment jig shown above. All crown nuts torqued to 67 ft-lbs plus whatever was needed to line up the cotter pin holes. The Trail Gear rods use jam nuts and do not have any indents to put a wrench on (!), so I tightened the tie rod jam nuts to TG's recommendation of 75-85 ft-lbs using a giant 14" set of vice grips and a giant adjustable wrench. I tightened the drag link jam nuts with just the wrench to "medium tight" because I knew I would need to adjust the steering wheel position a bit more. I did NOT install the new steering damper because one of the bolts was missing and Trail Gear has STILL today not delivered that missing bolt (they blame PROcomp, the steering damper manufacturer), but my understanding (which could definitely be wrong!) was that the steering damper just masks the issue and is never the root cause, so it seemed ok to leave it out initially. I also got my front wheels professionally balanced. Unrelated(?) to these fixes, I also installed a new Tom Woods DC front driveshaft.

Results

After these fixes, I drove a 38 mile loop including 23 miles of paved mountain roads like the ones that triggered so many wobbles. Zero wobbles. I did feel some "incipient shimmies" (vibrations like the ones that preceded death wobbles) which worried me a little, but I don't know the truck super well so I figured those may just be normal solid axle stuff. Given that I got 2 wobbles in 3 miles before the fixes, I thought for sure I would see wobbles in the big circuit if they were still a problem. The drag link did come loose from its jam nuts during the circuit because I hadn't done the final tightening yet, but even with the drag link working its way loose, still no wobbles. So, I considered the issue probably fixed and moved onto the next work.

Going to the picnic, I also had the AC shut off from overtemp while climbing a steep freeway grade on a hot day, so I did a bunch of cooling work next including replacing all of the heater hoses, replacing thermostat, replacing fan clutch with new 95F/6500cst-modded clutch, replacing radiator, and adding a temperature sensor to the upper radiator hose.

I went to do a short test drive to also re-set the drag link properly and...got a death wobble a short distance before my house. Well crap. I finished dialing in the drag link length and tightened the jam nuts to basically the gripping limit of the vice grips, then drove the same 38 mile loop. No death wobbles, but still a bunch of "incipient shimmies".

So, I don't really know what to do. I don't think tightening the drag link jam nuts should have made the difference between wobble and no wobble since I wasn't getting wobble on the big circuit even when the drag link was loose. But, it's also now apparently hard to actually reproduce the wobble. I feel like I can't take the LC on trips because I'll probably see wobble at some point since it was still present after all the fixes (not taking it on the trip I'm leaving for today because of this).

Configuration

When I bought the LC, it already had:

I had recently removed all wheels (one at a time), deflated, carefully and progressively torqued all 120 beadlock bolts, reinflated, and reinstalled.

Both the previous owner and the one before that are members of my offroad group (I joined shortly after getting this truck). The previous owner had a bunch of stuff put on the truck (including air locker), but drove it only a few hundred miles over 2 years. The second-previous owner (an experienced amateur mechanic) said the front axle "is basically all new" -- he said he thought he did the rebuild at 13Xk, but based on CarFax, I don't think he owned it until 145k (he works on a lot of cars, so not surprising his memory may not be perfect).

Possible things to try

I can think of a number of things that hypothetically might address the issue:

Thanks for reading; thoughts?

I know this is a bit long, so to encourage responses: I'd be excited to send $50 to whomever first describes a diagnostic procedure which leads to diagnosing an issue that, when fixed, solves the problem. Just throwing out things it could be doesn't count unless accompanied by some test I can perform to confirm or deny whether that thing is actually the main problem before spending money and time addressing it.

When it started

I'm completely new to Land Cruisers and vehicle maintenance in general. I bought this LC in March with 163k miles and I've been baselining it ever since, so I've put less than 1k miles on it. I thought I had the minimum set of stuff done in September so I took it to an offroad picnic about an hour away by paved roads. Just before hitting dirt, I got my first death wobble around 30 mph. I thought "that was crazy", but the pavement was a little rough and I hadn't heard about death wobble before, so I did a bit of light offroading then started home. A fire forced me to take (paved) back roads for 23 miles and I got probably 8 or 9 wobbles. By the end, I was trying to intentionally trigger them to figure out what the trigger was, and I was trying various things to mitigate them instead of just braking hard, but I couldn't find any reliable patterns.

Behavior

The wobbles always started between ~20 and ~55 mph -- I took it carefully on the freeway on the way home after the wobbles on the back roads and got zero wobbles on 28 miles of freeway, then one more wobble on the 1.5 miles between the freeway and my house. The wobbles seem to be more likely to happen while on a slight curve (especially when the curve direction changes), when hitting small bumps (but larger bumps don't seem to do it), and when slightly braking, but even a combination of all these factors doesn't guarantee a wobble, and not all factors are necessary to produce a wobble. Again, I could never figure out when they would or wouldn't happen.

Initial investigation

When I got home, I found the jam nut of my front adjustable panhard rod completely disengaged, so I tightened that jam nut. I could grab the drag link or tie rod and rotate them on their axis by hand fairly easily, but I didn't feel any play. I jacked up each front wheel one at a time and tried to wiggle the wheel while grabbing at 12 and 6 and I didn't feel any play. I tried to wiggle while grabbing at 3 and 9 and did turn the wheels a bit, but didn't notice any play. I took off the mud guard of the driver front wheel and looked at the frame and panhard tower around the steering box and didn't see any cracks. I measured 30.15 PSI in front passenger tire and 30.65 PSI in front driver tire, and both wheels still had balancing weights attached (though I can't rule out some falling off). The two of four knuckle nuts I could easily access with my torque wrench were still torqued to at least 71 ft-lbs and the other two were "tight" (both sides).

After tightening the panhard jam nut, I took it back out on a 45mph street and got 2 more wobbles within 3 miles. A member of my offroad club diagnosed needing new rod ends.

Attempted fixes

I bought the Trail Gear Heavy Duty Steering Kit which includes a new drag link, tie rod, 4 rod ends, and a steering damper. I took off both rods, damper, and the steering box and had the steering box professionally rebuilt. The old steering damper was pretty much entirely done -- spring only, virtually no oil resistance. When reinstalling the steering box, I replaced the high pressure hose with Gates and the low pressure hoses with Gates from phhkit.com. I installed the new tie rod and used two aluminum angles to set 1/8" toe in at 37" wheel diameter, using two laser pointers to center the steering:

I installed the new drag link and tried to center the steering wheel as closely as possible using the two laser pointers on my alignment jig shown above. All crown nuts torqued to 67 ft-lbs plus whatever was needed to line up the cotter pin holes. The Trail Gear rods use jam nuts and do not have any indents to put a wrench on (!), so I tightened the tie rod jam nuts to TG's recommendation of 75-85 ft-lbs using a giant 14" set of vice grips and a giant adjustable wrench. I tightened the drag link jam nuts with just the wrench to "medium tight" because I knew I would need to adjust the steering wheel position a bit more. I did NOT install the new steering damper because one of the bolts was missing and Trail Gear has STILL today not delivered that missing bolt (they blame PROcomp, the steering damper manufacturer), but my understanding (which could definitely be wrong!) was that the steering damper just masks the issue and is never the root cause, so it seemed ok to leave it out initially. I also got my front wheels professionally balanced. Unrelated(?) to these fixes, I also installed a new Tom Woods DC front driveshaft.

Results

After these fixes, I drove a 38 mile loop including 23 miles of paved mountain roads like the ones that triggered so many wobbles. Zero wobbles. I did feel some "incipient shimmies" (vibrations like the ones that preceded death wobbles) which worried me a little, but I don't know the truck super well so I figured those may just be normal solid axle stuff. Given that I got 2 wobbles in 3 miles before the fixes, I thought for sure I would see wobbles in the big circuit if they were still a problem. The drag link did come loose from its jam nuts during the circuit because I hadn't done the final tightening yet, but even with the drag link working its way loose, still no wobbles. So, I considered the issue probably fixed and moved onto the next work.

Going to the picnic, I also had the AC shut off from overtemp while climbing a steep freeway grade on a hot day, so I did a bunch of cooling work next including replacing all of the heater hoses, replacing thermostat, replacing fan clutch with new 95F/6500cst-modded clutch, replacing radiator, and adding a temperature sensor to the upper radiator hose.

I went to do a short test drive to also re-set the drag link properly and...got a death wobble a short distance before my house. Well crap. I finished dialing in the drag link length and tightened the jam nuts to basically the gripping limit of the vice grips, then drove the same 38 mile loop. No death wobbles, but still a bunch of "incipient shimmies".

So, I don't really know what to do. I don't think tightening the drag link jam nuts should have made the difference between wobble and no wobble since I wasn't getting wobble on the big circuit even when the drag link was loose. But, it's also now apparently hard to actually reproduce the wobble. I feel like I can't take the LC on trips because I'll probably see wobble at some point since it was still present after all the fixes (not taking it on the trip I'm leaving for today because of this).

Configuration

When I bought the LC, it already had:

- 37" Cooper Discoverer STT Pro tires with most of their tread life remaining

- Method 105 beadlock wheels

- OME 419 Comp Coils in front, unknown OME coils in back, resulting in ~5" lift based on DeltaVS's panhard bolt method when lightly loaded (but still have front & rear bumpers + winch on front + full-size spare on back)

- Front sway bar removed

- 5.29 diff gears (net result from 37" tires + 5.29 gears = truck travels 92% as far as speedometer/odometer thinks it went, so slightly lower gearing than stock)

- Air locker front, Detroit locker rear

I had recently removed all wheels (one at a time), deflated, carefully and progressively torqued all 120 beadlock bolts, reinflated, and reinstalled.

Both the previous owner and the one before that are members of my offroad group (I joined shortly after getting this truck). The previous owner had a bunch of stuff put on the truck (including air locker), but drove it only a few hundred miles over 2 years. The second-previous owner (an experienced amateur mechanic) said the front axle "is basically all new" -- he said he thought he did the rebuild at 13Xk, but based on CarFax, I don't think he owned it until 145k (he works on a lot of cars, so not surprising his memory may not be perfect).

Possible things to try

I can think of a number of things that hypothetically might address the issue:

- New non-beadlock wheels + new smaller (35"?) tires

- Knuckle rebuild, including new wheel bearings

- Install steering damper

- Add a front sway bar

- Replace some of the front axle components (not sure which ones)

Thanks for reading; thoughts?

.

. )

)