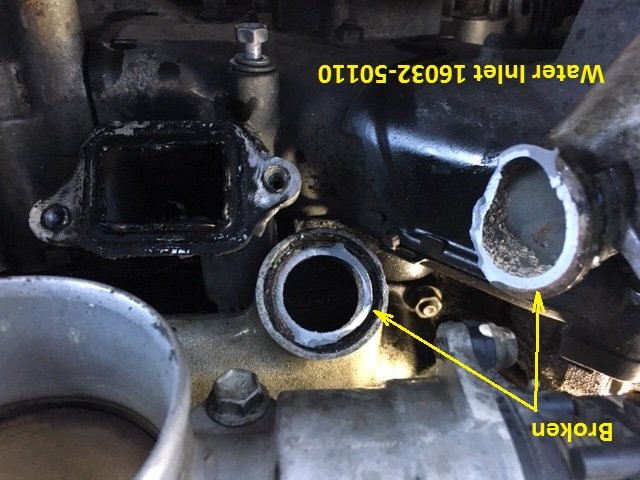

Diving into replacing my timing belt, water pump, etc....this afternoon.

Got to the Water Inlet/Tstat Housing. Knew it might give some trouble so I took my time with it. Tried and tried to wiggle it around in order to free it up, nothing doing.

Noticed that the last person in there used silicone on the bolts (no big deal) but also on the 'neck' of the housing. It wasn't going to budge. I rocked it back and forth for about 45 minutes making no headway. Finally resolved to snap it off of there....since it wasn't going to come out in one piece anyway.

NOW: How in the devil does one remove the broken off neck that is inside the bore? I have a new housing ordered but need to get the remains of the old part out.

I'm sure I'm not the first to experience this.

Sad part is: All previous work was done at a well known DEALERSHIP in Houston. You would think they would have done it right (no silicone where the O-Ring goes), but no...........

Got to the Water Inlet/Tstat Housing. Knew it might give some trouble so I took my time with it. Tried and tried to wiggle it around in order to free it up, nothing doing.

Noticed that the last person in there used silicone on the bolts (no big deal) but also on the 'neck' of the housing. It wasn't going to budge. I rocked it back and forth for about 45 minutes making no headway. Finally resolved to snap it off of there....since it wasn't going to come out in one piece anyway.

NOW: How in the devil does one remove the broken off neck that is inside the bore? I have a new housing ordered but need to get the remains of the old part out.

I'm sure I'm not the first to experience this.

Sad part is: All previous work was done at a well known DEALERSHIP in Houston. You would think they would have done it right (no silicone where the O-Ring goes), but no...........