94trilocked

Supporting Vendor

Out of personal DIY curiosity I am interested in paint products (and other auto care products) that have no VOCs, preferably organic, easy application/cleanup and long lasting. Before the modern petrochemical paint systems there were various other oil based systems. I'm not talking about various epoxys or urethanes.

From my personal experience using linseed oil based paints on wood for restoration - it takes a lot longer to apply (days drying between coats) - but I don't worry about it getting on my person or fight with cleanup or PPE, and it's generally OK to go down the drain or in the grass - there's nothing particularly harmful in it. Bottom line is it is forgiving and protects the parts. The benefit on wood is that it is not encapsulating the same way as a latex 'plastic' paint - the wood breathes and does not trap moisture. When latex fails it is because it traps moisture and essentially steams the wood, leading to paint bubbling and rotted wood - think about a F/G boat with a rotted transom.

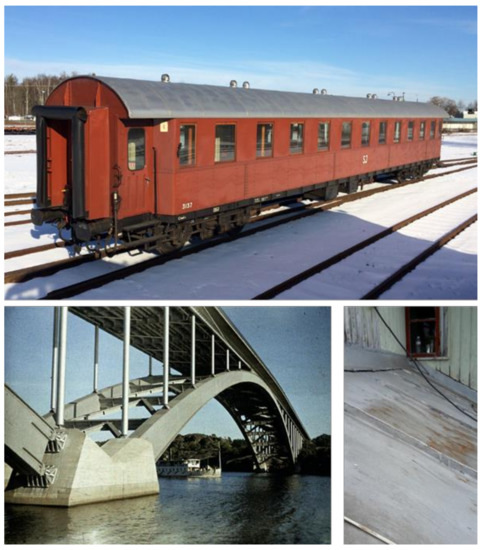

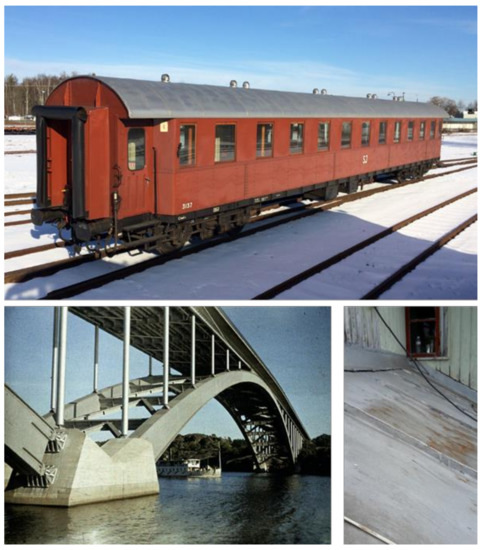

Bridges used to be primer'd with hematite or red lead carried in linseed oil (similar to red oxide primer the auto industry used to use). I suspect these systems were 'too good', inexpensive and not profitable for modern bridge painting outfits where they finish a bridge in 5 years and it's time to go back to the other side and start sandblasting and painting again. Think old formula Rustoleum Rusty Metal Primer, or the red oxide primer the auto industry used to use.

Typically these more organic type paints are long weathering and don't fail in a spectacular way if periodically maintained.

My 94 FZJ-80 has some significant rust in the rear chassis and axle housing/components. So, the plan is to clean them up and apply one of these linseed oil based primer systems and compatible top coat. I will take a bunch of before/after pictures and keep track of it over time.

The hematite carrying primer ("Iron Oxide Minium") is from a Swedish company called Ottoson, which has a distributor in PA. I already have a couple of linseed oil paints in various colors that are compatible with the primer.

Here is a recent study from Sweden on historical metal structures and the paint formulas they used.

www.mdpi.com

www.mdpi.com

Pretty science-y and I don't pretend to understand most of it, but I get the gist.

If anyone has any requests for me to consider on this project - I'll be your monkey - lemme know!

From my personal experience using linseed oil based paints on wood for restoration - it takes a lot longer to apply (days drying between coats) - but I don't worry about it getting on my person or fight with cleanup or PPE, and it's generally OK to go down the drain or in the grass - there's nothing particularly harmful in it. Bottom line is it is forgiving and protects the parts. The benefit on wood is that it is not encapsulating the same way as a latex 'plastic' paint - the wood breathes and does not trap moisture. When latex fails it is because it traps moisture and essentially steams the wood, leading to paint bubbling and rotted wood - think about a F/G boat with a rotted transom.

Bridges used to be primer'd with hematite or red lead carried in linseed oil (similar to red oxide primer the auto industry used to use). I suspect these systems were 'too good', inexpensive and not profitable for modern bridge painting outfits where they finish a bridge in 5 years and it's time to go back to the other side and start sandblasting and painting again. Think old formula Rustoleum Rusty Metal Primer, or the red oxide primer the auto industry used to use.

Typically these more organic type paints are long weathering and don't fail in a spectacular way if periodically maintained.

My 94 FZJ-80 has some significant rust in the rear chassis and axle housing/components. So, the plan is to clean them up and apply one of these linseed oil based primer systems and compatible top coat. I will take a bunch of before/after pictures and keep track of it over time.

The hematite carrying primer ("Iron Oxide Minium") is from a Swedish company called Ottoson, which has a distributor in PA. I already have a couple of linseed oil paints in various colors that are compatible with the primer.

Here is a recent study from Sweden on historical metal structures and the paint formulas they used.

Multianalytical Assessment of Armour Paints—The Ageing Characteristics of Historic Drying Oil Varnish Paints for Protection of Steel and Iron Surfaces in Sweden

The characteristics of armour paints, historically used to protect ferrous industrial heritage, are explored. Amour paints contain lamellar and highly reflexive pigments of micaceous iron oxide (MIO) and metallic, leafing aluminium, bound in linseed oil and linseed oil–tung oil mixtures, on an...

Pretty science-y and I don't pretend to understand most of it, but I get the gist.

If anyone has any requests for me to consider on this project - I'll be your monkey - lemme know!