- Thread starter

- #61

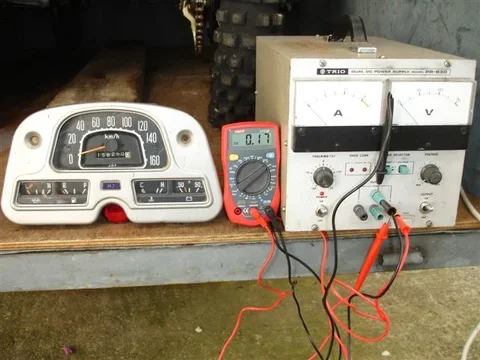

.... is it not also true that one must actually test the circuit to be sure that the voltage is significantly reduced.

Your right Pete. For curiosity's sake at least, I probably should have selected a link sizing that made my ammeter function and then tried taking measurements to discover the actual voltage reductions for various situations like

- Engine off but heater fan running, wipers running & headlights on,

- Engine off and turning the key to start

- Engine running with a relatively-flat battery (which would have the voltage drop in the opposite direction of course)

Or easier still .... I could have just taken these measurements when my original frayed link was there (and was providing good ammeter needle-deflections).

But then I think if I'd done this I'd probably have blown the link (.. if not from the first test ... then from the last one I've listed here)!

...Also we must remember that the majority of the current passes thru the fusible link when the engine is off and the alternator is not turning/supplying elec. And at least on my car this means that the only thing that will be getting current solely from the battery thru that fusible link is the starter and edic relay which if not pulling many amps should not cause much of a voltage drop.

Very true again.

But I wouldn't want my fusible link blowing immediately my alternator decides to fail. And knowing my luck such a thing would happen when I'm driving at night in the freezing cold with my heater and wipers going full-bore. And if that link blew in this situation it would immediately leave me stranded without lighting, heat or wipers. (And I believe the beefier fusible link I'm running now makes this sort of result FAR less likely.)

PS. So I guess you've rightly exposed the fact that my decision to abandon the idea of getting my ammeter to function is not as simple as I pretended it to be.

Edit: I just did some thinking about your choice of fuse size Pete:

...Right now my fusible link is blown and in its place is a 20 fuse as a temporary measure. And I have no problems starting and running my vehicle with just a 20 amp fuse. And as I said once its started current will be supplied by the alternator for the headlights, heater fans etc etc. I do have a spare and I will probably go to a 30 amp just to be o the safe side....

What is the output rating of your alternator? (My 1979 has a 35A alternator.)

I think your fuse should be sized to match your alternator output as a minimum requirement. Because I think you should allow for a dead flat battery absorbing its entire output (without your fuse blowing). So on that basis if I was to replace my link with a fuse I think I'd need one of at least 35A rating.

Or is my thinking flawed here?

(This further shows my reasoning for why I think the fuses/links must be so beefy - for reliability reasons - that their size prevents ammeter sensitivity.)

Last edited:

.

.

Finding these has been driving me crazy!

Finding these has been driving me crazy!