Awl_TEQ

Supporting Vendor

- Thread starter

- #721

Another Sunday swim class for the kids ( WIFI enabled at least )

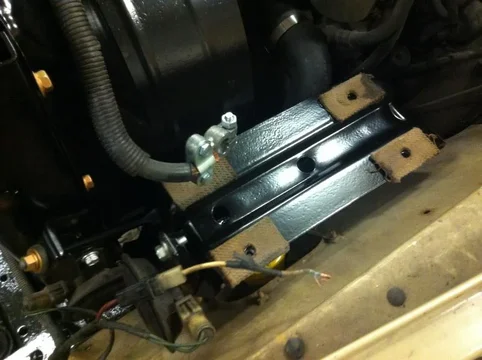

Yesterday I brushed some tremclad onto the visible areas of frame in the engine bay. I think it looks like crap. Hope you guys are happy.

Wasn't expecting it but got my powder and plating back on Friday

Yesterday I brushed some tremclad onto the visible areas of frame in the engine bay. I think it looks like crap. Hope you guys are happy.

Wasn't expecting it but got my powder and plating back on Friday

, might go for a hike today..

, might go for a hike today.. .

.