- Thread starter

- #81

Went out yesterday afternoon to work on the Cruiser. Marked a line to cut..Grab the grinder,...pull off a flap disk, to put on a cut off wheel. I walk to the other side of the garage..Grab the cut off wheel. When I get back, the "nut" that keeps the disk on the grinder is GONE.

Take a breath and start to trace the steps in my mind. "Its got to be right here". Look in all the obvious places that I might have set it. Nope.

Move to stage-two searching. "Maybe I dropped it, didn't pay attention, and it rolled away. Must be under something" Get on the floor, and look under everything in the garage. Nope. Began to mumble obscenities. Started cleaning up. Carry every cruiser part on the floor to my storage room, one by one. Put all my tools away. Grab a flashlight to look under stuff, inside the jackstands under the rig, etc. "It got to be right in front of me".

Stage three searching; Talking/cursing out loud to myself. Questioning my sanity. Pull everything out of the trash can, one by one, and put it in a new bag. "must have had trash in my hand at the time and thrown it away by mistake" Nope.

Stage four; sit down and drink a beer. Talk to myself some more....................

I am an idiot.

Went through my little stack of disks four or five times. I musta wasted 45 minutes to an hour...In a big-damn-hurry to get some work done.

I musta wasted 45 minutes to an hour...In a big-damn-hurry to get some work done.

Moral of the story; Sit down and drink the beer before moving to stage two. At least the garage is clean. (ish)

Take a breath and start to trace the steps in my mind. "Its got to be right here". Look in all the obvious places that I might have set it. Nope.

Move to stage-two searching. "Maybe I dropped it, didn't pay attention, and it rolled away. Must be under something" Get on the floor, and look under everything in the garage. Nope. Began to mumble obscenities. Started cleaning up. Carry every cruiser part on the floor to my storage room, one by one. Put all my tools away. Grab a flashlight to look under stuff, inside the jackstands under the rig, etc. "It got to be right in front of me".

Stage three searching; Talking/cursing out loud to myself. Questioning my sanity. Pull everything out of the trash can, one by one, and put it in a new bag. "must have had trash in my hand at the time and thrown it away by mistake" Nope.

Stage four; sit down and drink a beer. Talk to myself some more....................

I am an idiot.

Went through my little stack of disks four or five times.

Moral of the story; Sit down and drink the beer before moving to stage two. At least the garage is clean. (ish)

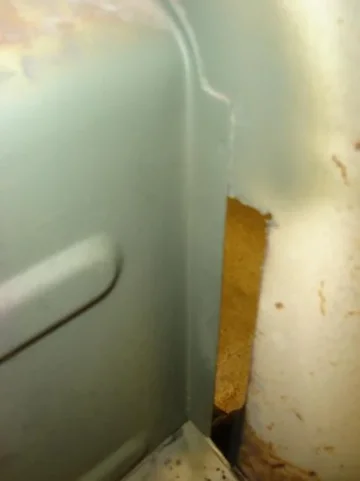

) I cut the door posts free, and then decided to order a spot weld cutter before going any further. I'm tired of using regular bits to drill them out. Since I was determined to get something done, I moved on to plan b. Stripping the frame, and engine of any remaining parts, and doing some preliminary cleaning.

) I cut the door posts free, and then decided to order a spot weld cutter before going any further. I'm tired of using regular bits to drill them out. Since I was determined to get something done, I moved on to plan b. Stripping the frame, and engine of any remaining parts, and doing some preliminary cleaning.

There was no budging 'em. Seized. On the bright side, plenty of stud is left on all three. So, hopefully I'll get them yet. I hate drilling out bolts, especially in the block. I cleaned up the threads at the base real good. I'll continue to hit 'em with PB for a while before I get back to them. I'm hoping to get the engine pulled and on a stand this weekend.

There was no budging 'em. Seized. On the bright side, plenty of stud is left on all three. So, hopefully I'll get them yet. I hate drilling out bolts, especially in the block. I cleaned up the threads at the base real good. I'll continue to hit 'em with PB for a while before I get back to them. I'm hoping to get the engine pulled and on a stand this weekend.