That's exactly what im doing with my air box.

I cut the square section off and added a 4" diameter elbow..

Im being lazy as I need to reroute my heater lines so that the rest of the air-box sits without rubbing into anything....

Im just wondering if the cheap snorkel flexhose will fit into the airbox intake without any more modifications.

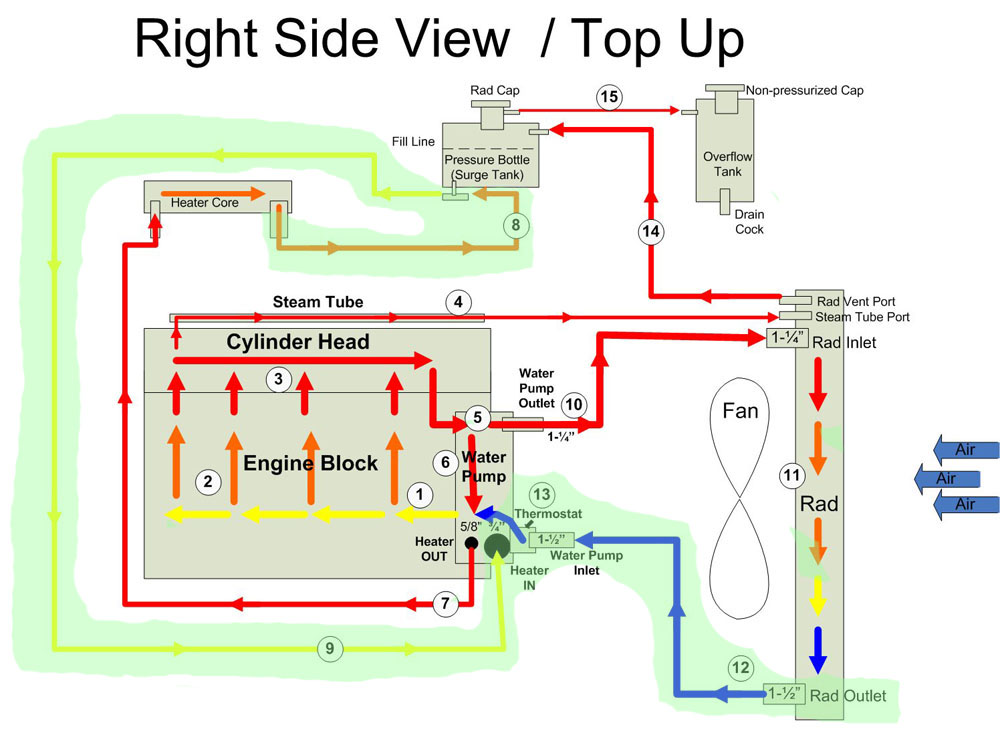

I like the idea of the steam-port into the radiator. I hooked mine to the heater hoses....

Got any more pics of that rad? it looks thicker than the stock rad.

Does it mount to the stock rubber grommets ?

I cut the square section off and added a 4" diameter elbow..

Im being lazy as I need to reroute my heater lines so that the rest of the air-box sits without rubbing into anything....

Im just wondering if the cheap snorkel flexhose will fit into the airbox intake without any more modifications.

I like the idea of the steam-port into the radiator. I hooked mine to the heater hoses....

Got any more pics of that rad? it looks thicker than the stock rad.

Does it mount to the stock rubber grommets ?