Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do with your 60 this weekend? (38 Viewers)

- Thread starter MrMoMo

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?- Joined

- Jun 21, 2011

- Threads

- 233

- Messages

- 21,821

- Location

- Redding, California

- Website

- trail-tailor.com

464 tan BC/CC complete. Now to decide what direction to go with this cruiser.

J

J

suzuguru

SILVER Star

Making a fj60 twin stick kit from cruiser outfitters work on a fj40 because it has a split case from a late 60and 4l60e. What a mess. These were really hard to position on the table lol

View attachment 3282266

View attachment 3282267

View attachment 3282268

I wish I had a TIG welder. I used to be pretty slick with one, but I haven't TIG'ed in about 20 years. I just can't seem to justify buying one. Nearly everything I do, can be done with a MIG.

Man I’ve gotten to the point where unless it’s too big to fit on my table or up under the truck I’m going to tig it. It’s so much cleaner and more precise. No spatter holes in my clothes haha. It also challenges you to get your fit up to be pretty much perfect which means your joints will be stronger anyways.I wish I had a TIG welder. I used to be pretty slick with one, but I haven't TIG'ed in about 20 years. I just can't seem to justify buying one. Nearly everything I do, can be done with a MIG.

As far as the machine, I use an everlast 185DV. I got it on sale for $700 and upgraded the pedal and gas line and couldn’t be happier. It does AC/DC up to 185 amps which is a pretty healthy number. Sometimes the torch can get hot on thick cast aluminum repairs like aluminum engine blocks but a water cooler would fix that. I learned on this machine and was planning on upgrading but I haven’t really found the need to. The one thing I wish I had was more control over pulse settings.

My Mig welder is a miller211 and imo it’s a complete waste of money. The everlast that is similar has the same specs at half the price.

If you don’t need to do aluminum the DC only tigs get even cheaper

suzuguru

SILVER Star

Man I’ve gotten to the point where unless it’s too big to fit on my table or up under the truck I’m going to tig it. It’s so much cleaner and more precise. No spatter holes in my clothes haha. It also challenges you to get your fit up to be pretty much perfect which means your joints will be stronger anyways.

As far as the machine, I use an everlast 185DV. I got it on sale for $700 and upgraded the pedal and gas line and couldn’t be happier. It does AC/DC up to 185 amps which is a pretty healthy number. Sometimes the torch can get hot on thick cast aluminum repairs like aluminum engine blocks but a water cooler would fix that. I learned on this machine and was planning on upgrading but I haven’t really found the need to. The one thing I wish I had was more control over pulse settings.

My Mig welder is a miller211 and imo it’s a complete waste of money. The everlast that is similar has the same specs at half the price.

If you don’t need to do aluminum the DC only tigs get even cheaper

I'm sure if I had one, I would probably use it more than really necessary. The one I used every day years ago was water cooled. It made it really nice. It was a Lincoln Square Wave 250. It had a pulse setting, of course, but I used to pulse manually with the foot pedal. I became really good at that. I could lay down some beautiful welds on the stainless I was working with. I often wonder how long it would take me to get back to that point after not doing it for 20 years.

I'm sure if I had one, I would probably use it more than really necessary. The one I used every day years ago was water cooled. It made it really nice. It was a Lincoln Square Wave 250. It had a pulse setting, of course, but I used to pulse manually with the foot pedal. I became really good at that. I could lay down some beautiful welds on the stainless I was working with. I often wonder how long it would take me to get back to that point after not doing it for 20 years.

Man honestly I bet you could get it back pretty quick. For me it was all seat time to learn. I just did 30 min a day all last summer and now I can not touch the machine for a month and hop on it like nothing changed.

Man I’ve gotten to the point where unless it’s too big to fit on my table or up under the truck I’m going to tig it. It’s so much cleaner and more precise. No spatter holes in my clothes haha. It also challenges you to get your fit up to be pretty much perfect which means your joints will be stronger anyways.

As far as the machine, I use an everlast 185DV. I got it on sale for $700 and upgraded the pedal and gas line and couldn’t be happier. It does AC/DC up to 185 amps which is a pretty healthy number. Sometimes the torch can get hot on thick cast aluminum repairs like aluminum engine blocks but a water cooler would fix that. I learned on this machine and was planning on upgrading but I haven’t really found the need to. The one thing I wish I had was more control over pulse settings.

My Mig welder is a miller211 and imo it’s a complete waste of money. The everlast that is similar has the same specs at half the price.

If you don’t need to do aluminum the DC only tigs get even cheaper

I have a Miller 210 at home, it can even do aluminum.

I’m going to welding school and I’m probably going to buy a tig welder. But I have always found the Mig to be so good.

As someone who is currently dismantling their interior, with plans to take out the whole dash down to the firewall, this picture gives me anxiety.I’m doing tonnes of wiring right now, it seems almost impossible to swap in a 3FE. I could only imagine.

View attachment 3282147

4 new shocks and Boss Airbags in the rear to help when loaded down with gear. This thing drives like a big sports car now!View attachment 3275777View attachment 3275778View attachment 3275783View attachment 3275785View attachment 3275786

Been thinking of replacing the OME shocks on mine. What PN are those? I have a 2" OME suspension. Also, is the Dampening noticeably better?

Been thinking of replacing the OME shocks on mine. What PN are those? I have a 2" OME suspension. Also, is the Dampening noticeably better?

Do it. Bilstein is an improvement over OME.

You could direct it into my driveway.464 tan BC/CC complete. Now to decide what direction to go with this cruiser.

J

View attachment 3282274View attachment 3282275View attachment 3282277View attachment 3282278View attachment 3282279

As someone who is currently dismantling their interior, with plans to take out the whole dash down to the firewall, this picture gives me anxiety.

I bet it’s way easier than you think.

garfieldthecat

SILVER Star

464 tan BC/CC complete. Now to decide what direction to go with this cruiser.

J

View attachment 3282274View attachment 3282275View attachment 3282277View attachment 3282278View attachment 3282279

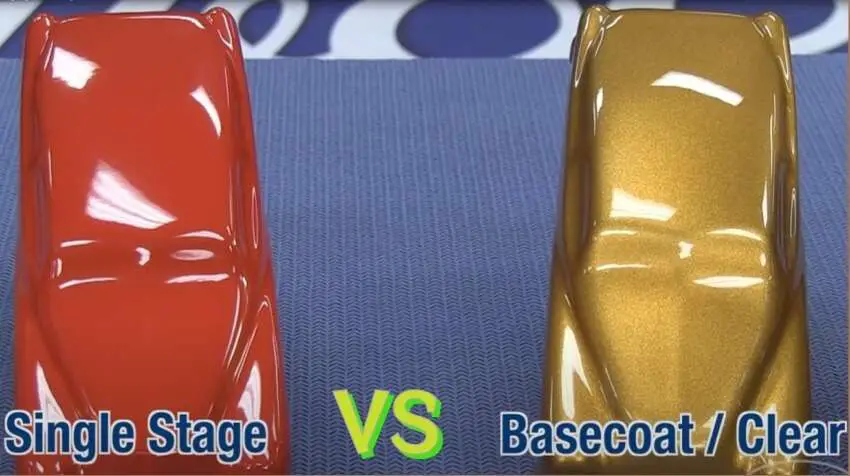

Is the BC/CC preferable to the original single stage paint?

- Joined

- Jun 21, 2011

- Threads

- 233

- Messages

- 21,821

- Location

- Redding, California

- Website

- trail-tailor.com

Is the BC/CC preferable to the original single stage paint?

I prefer BC/CC and 95% of my rigs and customers builds I apply BC/CC

A little reading:

Base Coat Clear Coat Vs Single Stage: What's The Difference

Do you know the difference between base coat clear coat and single stage? Learn how to select the proper paint system for your next project

autoguidehub.com

autoguidehub.com

Hey it works perfect! Im pretty surprised, because I added a TON of length to these, but there isnt any wiggle at all. This setup is way better than whats in my 60. The extra 8 inches of vertical height is because the height of the trans tunnel cover on the fj40 is super super tall

It’s still going to feel stiff because they’re both digressive shocks but the 5100s are a better shock. Try and find a linear or progressive shock if you’re looking for more comfortBeen thinking of replacing the OME shocks on mine. What PN are those? I have a 2" OME suspension. Also, is the Dampening noticeably better?

Finished swapping out the stock seats for some new (to me) Recaro LX seats

I reused the bases/sliders from the stock seats, though I had to break them down and rebuild them to adapt the wider Recaro bolt spacing to the mounting points in the cruiser’s floor.

Plan from here is to strip down the stock front seats and scavenge the reusable upholstery. I’ll eventually replace the diagonal striped fabric on the Recaros with stock striped fabric.

I also plan to cut the headrest portion of the frame out and adapt that to the rear seat so I can get headrests back there. Then I’ll add 3pt belts from seatbelt planet (used a dental pick to confirm the pillar has the anchor in there already, luckily).

This has all been an interruption to the new h55f I’m prepping on the bench for install soon(ish)

I reused the bases/sliders from the stock seats, though I had to break them down and rebuild them to adapt the wider Recaro bolt spacing to the mounting points in the cruiser’s floor.

Plan from here is to strip down the stock front seats and scavenge the reusable upholstery. I’ll eventually replace the diagonal striped fabric on the Recaros with stock striped fabric.

I also plan to cut the headrest portion of the frame out and adapt that to the rear seat so I can get headrests back there. Then I’ll add 3pt belts from seatbelt planet (used a dental pick to confirm the pillar has the anchor in there already, luckily).

This has all been an interruption to the new h55f I’m prepping on the bench for install soon(ish)

Last edited:

These are sooooooo good. Hell yesFinished swapping out the stock seats for some new (to me) Recaro LX seats

View attachment 3282802

I reused the bases/sliders from the stock seats, though I had to break them down and rebuild them to adapt the wider Recaro bolt spacing to the mounting points in the cruiser’s floor.

View attachment 3282805

Plan from here is to strip down the stock front seats and scavenge the reusable upholstery and then cut the headrest portion of the frame out and adapt that to the rear seat so I can get headrests back there. Then I’ll add 3pt belts from seatbelt planet (used a dental pick to confirm the pillar has the anchor in there already, luckily).

Prior to shifting over to cruisers I’d run Recaros in pretty much all of my project cars, though usually with bigger bolsters to keep me more planted in the corners. This particular set has shorter thigh bolsters (“A” model bases), which are intended more for trucks and commercial vehicle use and won’t get as beat up climbing in and out. I tried to mount them as low as possible for a bit more headroom.These are sooooooo good. Hell yes

I have a set of the very 80’s fish net headrests I may recover to match and swap in, too. Besides just liking the appearance, they’d probably also help maintain the cruiser’s good 360 visibility for passengers.

nice! now i have a good idea as to how my 1st gen 4runner seats are gonna look in my 60, thanks. i'd love a set of recaros but i like the 1st gen 4r seats, the price was right, free.95Finished swapping out the stock seats for some new (to me) Recaro LX seats

View attachment 3282802

I reused the bases/sliders from the stock seats, though I had to break them down and rebuild them to adapt the wider Recaro bolt spacing to the mounting points in the cruiser’s floor.

View attachment 3282805

Plan from here is to strip down the stock front seats and scavenge the reusable upholstery. I’ll eventually replace the diagonal striped fabric on the Recaros with stock striped fabric.

I also plan to cut the headrest portion of the frame out and adapt that to the rear seat so I can get headrests back there. Then I’ll add 3pt belts from seatbelt planet (used a dental pick to confirm the pillar has the anchor in there already, luckily).

This has all been an interruption to the new h55f I’m prepping on the bench for install soon(ish)