I was told not to tig weld aluminum ac fittings because the aluminum oxides will contaminate the compressor/condenser/evaporator etc

So that leaves aluminum brazing. I did a little research and picked up some flux filler rod and gave it a whirl.

I spent a long time cleaning and deburring. Chemically cleaning, stainless steel brushing etc.

Fired up the torch and created this !

My own damn fault for not testing on some other material...dummass

Turns out the filler rod they sold me melts at 1050 degrees...

Pool of molten drool.

For reference - the one on the left is what the part is supposed to look like

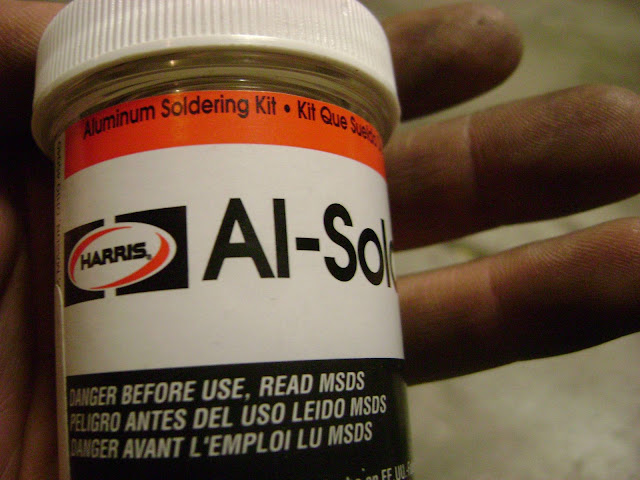

Turns out I need this

other really expensive filler material

Al-solder 500

This little amount cost 30bux !

Coil of solder

The ever important Flux

Heres the mockup

I got the parts mocked up and test fit. Broke out the torch and got to work. This worked about 500% better than the last try, but the fittings leak out of every joint.

I decided I cant wait for these fittings any longer so Im moving on.

Time to move on......without ac