Ok. I'm in same boat. Looking what pitman arm is best. I'm going SUA so more room for the drop but like to keep it tight.No, I didn't have to notch the frame, but it is very tight. The rods were custom length from Marlin. Steering arms were the FJ80 style from Luke at 4x4Labs.

-

North American Clubhouses - East RegionCA.ON- SOTEC CA.ON- Upper Canada Land Cruisers CA.QC- Club TORQ CA.QC- Quebec Cruisers AL- DixieLand Cruisers AL- Hot South Cruisers FL- Florida Land Cruiser Association FL- Northwest Florida Toyota 4WD FL- Tampa Bay Land Cruiser Association GA- Pavement Pounders GA- Georgia Cruisers GA/FL/AL- Red Hills Land Cruiser Club GA- YOTA IL- Windy City Land Cruisers IN- Hoosier Cruisers IN- Indiana Land Cruisers KY- Kentucky Landcruiser MA/NH- Yankee Toys MI- Lake Michigan Land Cruisers MS- CottonLand Cruisers NC- Olde North State Cruisers NJ- Garden State Land Cruisers NY/CT/MA- FJNortheasters NY- Gotham City Land Cruisers OH- The Buckeye Birfield Syndicate PA- Keystone Cruisers PA- Steel City Land Cruiser Club SC- Palmetto State Land Cruiser Association SC- Upstate Cruisers SC- Swamp Fox Land Cruisers SC- Low Country Land Cruisers TN- Appalachia Cruisers TN- Bluff City Cruisers TN- STLCA VA- Bay to Blue Ridge Cruisers VA- COVA CRUISERS VA/DC/MD- Capital Land Cruiser Club VA/NC- Mid-Atlantic TLCA VA- Star City Land Cruisers VT/NH/MA/ME Acadian Overlanders WI- Land Cruiser Legends WV- Mountaineer Cruisers

-

North American Clubhouses - Central RegionCA.AB- Oil Country Cruisers CA.AB- Rocky Mountain Land Cruiser Association CA.AB- Toyota Ghost Wheelers AR- Razorback Land Cruisers AR/MO- Ozark Mountain Cruisers CO- BookCliff Cruisers CO- Colorado Land Cruisers CO- Derailed Cruisers CO- Rising Sun 4WD Club CO/WY- Horsetooth 4 Wheelers Cruiser Club IA- Tall Corn Cruisers KS/MO- Tornado Alley Cruisers LA- Bayou State Land Cruisers LA- Louisiana Land Krewesers MO- Gateway Cruisers MT- 406 Cruisers MT- Big Sky Cruisers NE- Flat Land Cruisers NM- High Desert Cruisers OK- Green Country Cruisers SD- Dakota Territory Cruisers TX- Alamo City Land Cruisers TX- Bayou City Land Cruisers TX- Lone Star Land Cruisers TX- Lone Star Land Cruisers - Austin Chapter TX- The White Trash of the Elwood Chapter TX- Toyota Trail Riders

-

North American Clubhouses - West RegionCA.BC- Coastal Cruisers CA.BC- Okanagan-Similkameen Land Cruisers CA.BC- Peace Canyon Toyota Swamp Donkeys CA.BC- Calgary Chapter: Swamp Donkeys

CA.BC- Vancouver Island Cruisers AZ- Copper State Cruisers CA- Beach-n-Toys CA- Central Coast Land Cruisers CA- Central Valley Crawlers CA- Gold Country Cruisers CA- Inland Empire Cruisers CA- L.A. County Trailcrew CA- Mountain Transit Authority CA- Pacific Mountain Cruisers CA- San Diego Cruisers CA - Santa Cruz Land Cruisers CA- SoCal 80's CA- Southern California Land Cruisers CA- Toyotally Awesome Cruisers HI- Hawaiian Island Land Cruisers ID- Treasure Valley Land Cruisers NV- Battle Born Cruisers of Northern Nevada NV- Southern Nevada Land Cruisers OR/CA- Jefferson State Cruisers OR- Cascade Cruisers OR- Central Oregon Cruisers OR- Portland Metro Cruisers UT- Red Rock Cruiser Club UT- Wasatch Cruisers WA- Central Washington Cruisers WA- North Sound Cruisers WA- South Sound Cruisers WA- Spokane Land Cruisers

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Builds Project "Devil Frog" - Isaac's '69 FJ40

- Thread starter Devil Frog

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?- Thread starter

- #282

So the a/c compressor is right where the factory battery tray goes, so I need to scoot it back a few inches, which entails fabrication of a new tray mount.

- Thread starter

- #283

Nice progress. The battery looks like the factory location. How was it relocated? Also, you have a breather on the valve cover. Keep in mind that you will be sucking in unmetered air through the PCV and that will probably create a problem. In the factory configuration, the breather fitting would be hooked up on the intake tube after the AFM.

- Thread starter

- #285

The factory location interfered with the compressor. I fabricated a new mount, it is still tied into the main frame rail, but moved the location back a few inches just behind the AC compressor. The new mount it’s just some angle iron and sheet-metal I welded up.

With the PCV I am venting to atmosphere which is fine for performance, it’s necessary to not let blow-by products accumulate in the crankcase. The factory set up recirculated this back into the intake tract with vacuum for a emissions purposes, this won’t work for me because with the turbo charger will have positive pressure instead of vacuum pressure which will actually make things worse in side the crankcase. With the filter on the PCV port I am venting to atmosphere which is will allow blow-by to vent, the crankcase. This 40 is a ‘69 so is exempt from emissions.

With the PCV I am venting to atmosphere which is fine for performance, it’s necessary to not let blow-by products accumulate in the crankcase. The factory set up recirculated this back into the intake tract with vacuum for a emissions purposes, this won’t work for me because with the turbo charger will have positive pressure instead of vacuum pressure which will actually make things worse in side the crankcase. With the filter on the PCV port I am venting to atmosphere which is will allow blow-by to vent, the crankcase. This 40 is a ‘69 so is exempt from emissions.

Nice progress. The battery looks like the factory location. How was it relocated? Also, you have a breather on the valve cover. Keep in mind that you will be sucking in unmetered air through the PCV and that will probably create a problem. In the factory configuration, the breather fitting would be hooked up on the intake tube after the AFM.

any new updates???

- Thread starter

- #287

any new updates???

Unfortunately no, between 3 boys under 8 years old and 3-4 jobs progress is slow to non-existent. I was thinking of taking a week of stay-ation in September and just doing FJ40 work. Wiring and hydraulic lines are about all the significant work left.

- Thread starter

- #288

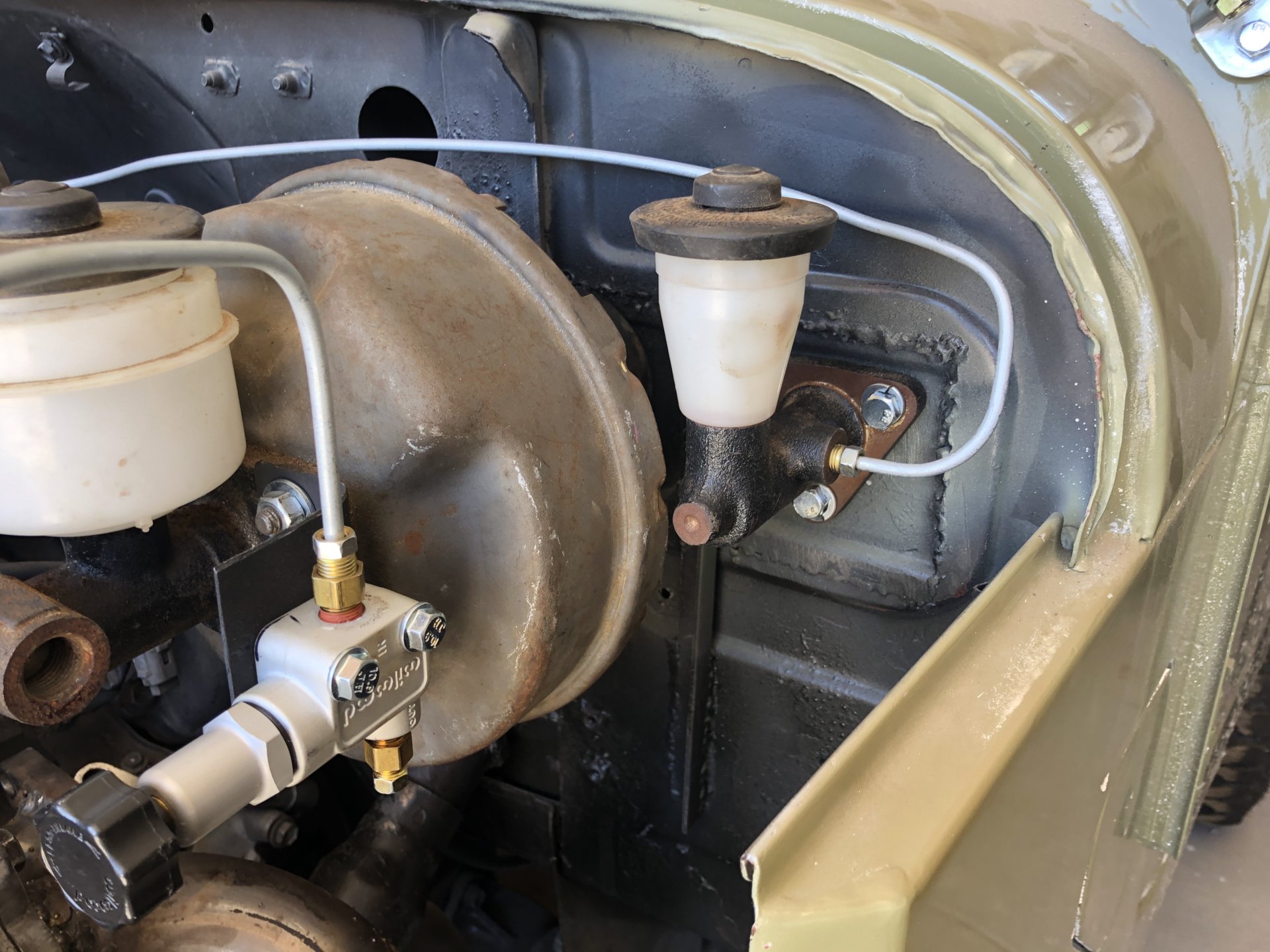

Finally got all the tooling I need to do the brake lines. I started with plumbing in a proportioning valve given the all disc setup.

Last edited:

- Thread starter

- #290

What adapters are you using there? I'm about to buy that same proportioning valve. Looks like I can get one with a M10x1.0 from Willwood (p/n 260-12627)

Used 3/8”-24 for proportioning valve, everything else will be M10x1.0

alia176

SILVER Star

Whats with these lifelong 40 projects, y'all? Get it done already  Pappy did the same thing too.

Pappy did the same thing too.

Pappy did the same thing too.

Pappy did the same thing too.Whats with these lifelong 40 projects, y'all? Get it done alreadyPappy did the same thing too.

So Justin should not buy a new project but rather buy a finished project aka pappys 40? Think he’s funded from the sale of his house....Whats with these lifelong 40 projects, y'all? Get it done alreadyPappy did the same thing too.

- Thread starter

- #294

Yeah I know, well deserved.

I actually welcome the taunts and pressure to finish. I got too many excuses, mainly time, but at least space and money are no longer on the list. All the really expensive items are bought and I have a detached workshop.

That little green man was directed at Ali, who was on the gang that razzed me about getting my FJ40 done.Yeah I know, well deserved.

I actually welcome the taunts and pressure to finish. I got too many excuses, mainly time, but at least space and money are no longer on the list. All the really expensive items are bought and I have a detached workshop.

- Thread starter

- #296

Whats with these lifelong 40 projects, y'all? Get it done alreadyPappy did the same thing too.

Yeah I know, well deserved.

I actually welcome the taunts and pressure to finish. I got too many excuses, mainly time, but at least space and money are no longer on the list. All the really expensive items are bought and I have a detached workshop.

- Thread starter

- #297

That little green man was directed at Ali, who was on the gang that razzed me about getting my FJ40 done.

Yes I got it, screwed up the quoting thing. I am MUD rusty

- Thread starter

- #298

It’s getting tight in the engine bay

Last edited:

alia176

SILVER Star

PORN!!!

- Thread starter

- #300

Started attacking the wiring. I am adapting the FJ62 EFI and main (cowl) harnesses. The big plus is that a lot of things are plug-n-play, the big negative is there’s a lot of unneeded connectors coming off of it, for example power windows power doors. I’ve wired enough where the headlights get power on and I can get the starer to engage with a turn of the key. I will be wiring in a custom instrument panel, engine sensors, OBA, and vintage air HVAC, which will require some modifications. Can’t give enough credit to Jon (Pappy), and trails he has blazed in for 3FE FJ40 retrofit.

Last edited:

Similar threads

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)