TeddyBoy

Knighted by the King of MUD himself

How bout this?

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

.

.Well folks, I am still at it building my rear bumper. Forgot where I left off other than pondering what I should do with my muffler.....

A while back, I was at Chuck's to reinforce my frame brackets and added some 3/16" plate to the 1/4" in one area that has a potential weakness.

I also drilled all of my holes for my brackets, (7 per side including originals) I guess that should be enough...

so anyway here are some pictures....

View attachment 396085

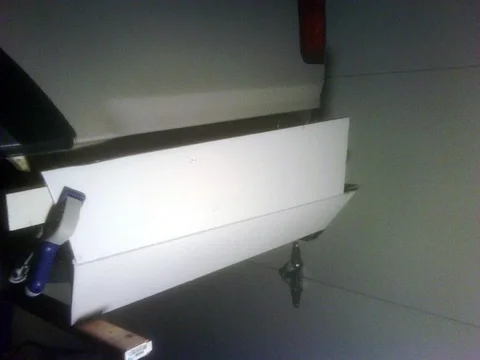

test fit of bumper (above), bit lower than I would like it to be, but I would revise the design in my next life.

View attachment 396086

Here is one of the most tricky parts above, designing the internal frame brackets, everyone said to "plate" the frame, but I have never seen any pictures on the net so here are mine. 2 of them with welded bolts and painted.

They are very difficult to make esp. the back one as it sits about 10" into the frame and had to be cut and ground in a few special areas.

View attachment 396087

again, in the above picture, they are just loosely bolted to test fit. I hope that will be enough steel around them.

Larry, process of elimination I guess would sum it up.Andrew,

Nice work on the internal nut plates. So how did you locate both nuts on that bracket and blind fit all the cuts/contouring so it would fit and bolt up? Build thread within a build thread.

... The file gives me the ability to get a better finish than the grinder. (really needed a bench grinder)

...

Are you using flap disks on your 4 1/2" grinder yet? Depending on grit choice, they can yield a nice surface finish too (and fairly quickly)

Stay away from Makita 4 1/2" angle grinders

Guess you got a lemon thenI have 2 of them that have been put thru very hard use over the years. These are older models, say early 2000's. I have recently retired one of them due to an overworked bearing. I use these two grinders more than any other tool I own, they survived 2 trail rig buildups

. I would stay away from DeWalt 4 1/2" grinders. That POS gets hot within 5 minutes of use on easy cleanups. Dunno about Milwaukee, I don't like their trigger flap on the bottom

it was a "hamedown" tool....

it was a "hamedown" tool....Nicely documented pillguy. Wish I understood more about all that you are doing. Is the bumper really as wide as some of those photos make it look?