I just posted a toyota dealership quote. Two days ago. $580+ per side in parts. Plus another $400 something for labor per side.how much is the shop rate for this job anyone know? dealer or indy. so I can bask in pride LOL

Gaining some confidence in doing this now. thanks for the tips and replies.

I am attempting to remove the old race, cut it and use it to install the new one. second day now still on one side haha. wish me luck.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Noob attempt to replace front rotors pads and bearings (4 Viewers)

- Thread starter bobNoobie

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?I just posted a toyota dealership quote. Two days ago. $580+ per side in parts. Plus another $400 something for labor per side.

Wow. What can I get for a smooth $1400?

Sorry, that did not include brakes either.Wow. What can I get for a smooth $1400?

Just seals and bearings.

Sorry, that did not include brakes either.

Just seals and bearings.

That is insane. I had never done the job before and it took me about 5 hours, and I really took my time getting the preload set and making sure everything was right.

Hell, I wouldn't even trust a dealership to do the job per the FSM. Mine was documented to have been done by a Lexus dealer and my adjusting nut was hand tight, and had chisel marks on it from removing/replacing it. If I paid that much I'd either want to be able to watch the tech do it, or have him explain to me how he was planning to do it.

I just ordered 4 new brake calipers that someone posted in this thread, brake pads for all 4 corners, and two of the bearing kits from CruiserTeq for a total of $391.That is insane. I had never done the job before and it took me about 5 hours, and I really took my time getting the preload set and making sure everything was right.

Hell, I wouldn't even trust a dealership to do the job per the FSM. Mine was documented to have been done by a Lexus dealer and my adjusting nut was hand tight, and had chisel marks on it from removing/replacing it. If I paid that much I'd either want to be able to watch the tech do it, or have him explain to me how he was planning to do it.

I also threw in the Baofeng BF-F8 HAM radio as well.

But don't tell my wife.

But don't tell my wife.

Since you've been driving. The grease (assume you greased the axle bearing and bushing) will be settled. So simple pull grease cap off while tire on ground or jack under lower control arm. This keeps FDS (AKA CV) axle from being pulled inward. Then thread a 8 x1.25mm bolt into end of axle and pull on it. This is all just to make sure axle is pulled out as far as possible, while checking gap. Then place a feeler gauge between hub flange and snap ring. Spec is less than 0.20mm gap. If at or over, go up to next thicker size snap ring that yeild less than 0.20mm gap.

View attachment 2604909

As you can see this gap is way over 0.20mm at 0.56mm. Here we'd go up 2 sizes adding 0.40mm to thickness of current snap ring. The end result would be a gap on 0.16mm. Which 0.16mm would be a gap wider than I like to see, but within spec. I would try to get 3rd size up into grove first, as I pulled out axle as hard as I reasonable can.

View attachment 2604910

I keep bags of new snap rings of various sizes. I start at 2.8mm thickness and work down until I get one that fits in the groove. I use the 2.4mm (90520-31007) the "D" most often and 2.6mm (90520-31006) the "C" second most.

Note: if you use the 2.0mm or 1.80mm snap ring, I'll bet your gap is to wide. I'll bet you've not pulled the axle hard enough or settled the grease. Never, not even when replacing bearings, races, brass bushing, FDS and hubs with all new OEM parts, do use those thin snap rings used.

View attachment 2604938

Most often I'm setting snap ring gap after a full wheel bearing and knuckle service. Where I have greased the axle bearing & bushing (PM is every 30K miles) and installed a new seal.

View attachment 2604926

Or I've used my Slee greasing tool to grease the axle needle bearing and brass bushing.

View attachment 2604944

In these it's important to settle the grease between the FDS outer axle on brass bushing in back of knuckle. Here's old video of tools found in the shop to make a puller. I and other have made various tools for pull axle to settle grease and set snap ring.

Why we need "Slee greasing tool" here? I assume we should already take off all the parts then greased all of them when reinstalling back.

And if I use a Slee greasing tool, how do you tell there is enough grease?

And when to use it? After putting on the first lock nut? Before the preload or after?

Thanks!

Last edited:

ramangain

Clarksonian disciple

The Slee greasing tool is used to get grease inside of the spindle with everything installed EXCEPT the snap ring, outer spindle nut, and spider lock washer (and hub flange obviously). It allows grease to flow into the spindle and oozes out of the back of the spindle around the spindle seal.

If you coat the inside of the spindle with (fresh) grease before installing the axle, you shouldn't need to use the Slee greasing tool. The Slee greasing tool is used to be able to get grease inside of the spindle without removing the axle (which usually involves removing one or more castle nuts and popping ball joints).

If you coat the inside of the spindle with (fresh) grease before installing the axle, you shouldn't need to use the Slee greasing tool. The Slee greasing tool is used to be able to get grease inside of the spindle without removing the axle (which usually involves removing one or more castle nuts and popping ball joints).

2001LC

SILVER Star

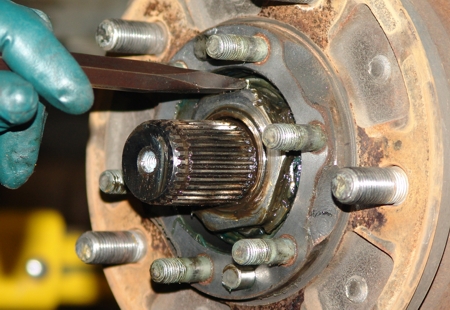

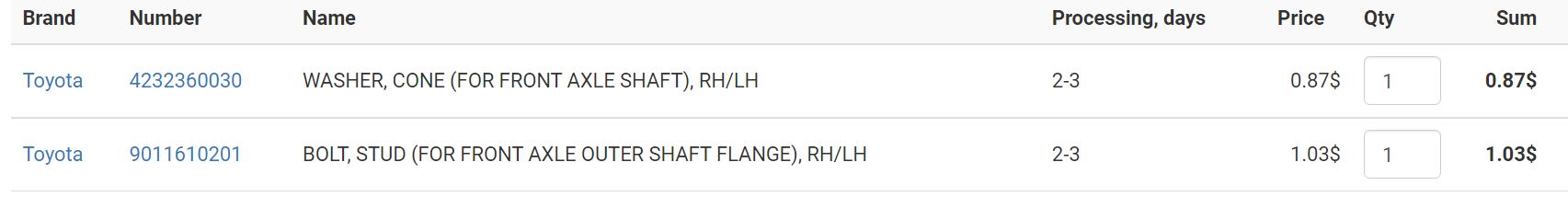

Use either the double nut method, after cleaning threads, or a stud tool. I torqued to ~24-27ft-lbf with thread locker to seal the threads.i had 2 of the hub studs come out with the nut when removing the cone washers. what's the method to get these back in?

Double nut is difficult to get torque to even 21ft-lbf as, as not much thread length to work with..

10x1.25mm stud tool works better, but for DIY not a big deal to have.

You can even make a stud tool with coupling nut DIY.

All to often the steering knuckle spindle, axle passes thought, has gotten dirty due to bad grease cap or rear knuckle seal, etc.. So just greasing with the Slee spindle tool, we may force dirty into axle needle bearing & bushing.Why we need "Slee greasing tool" here? I assume we should already take off all the parts then greased all of them when reinstalling back.

And if I use a Slee greasing tool, how do you tell there is enough grease?

And when to use it? After putting on the first lock nut? Before the preload or after?

Thanks!

So I like removing steering knuckle and recondition it, first time in to any wheel bearing service. Recondition it by removed rust, flattening out surface pounded on to pop ball joint warping boot seat area, rather than using a ball joint puller. The warped area is of concern as boot need the area flat so dirty and water does not get into boot, between warp and flat area.

Final reconditioning is to clean and inspect axle needle bearing & bushing. Than we pack axle needle bearing and bushing with grease. With new seal in back of knuckle and grease cap on front. I know inside of spindle and axle is now clean. So I use the Slee spindle tool on second wheel bearing service at each 30K mile interval.

Greasing front spindle bushing - UZJ100 - Slee Off Road

Once you have removed the dust cap and drive flange, you expose the axle stub shaft were the wheel hub nuts can be accessed.

sleeoffroad.com

sleeoffroad.com

Last edited:

You do not want to pounding on hub flange or wheel hub, Doing so can warp them. Then hub flange may not seal well to wheel hub (water entry issues) and or not center axle well. Also if hit at cone wash seat, it warps the centering hole (seat) for cone washer.

View attachment 2576433

View attachment 2576434

I spent the time needed taking down high spot to correct/flatten these wheel hubs that have been pounded on (warped).

View attachment 2576436

View attachment 2576315

Do not use old race with new wheel bearings. If replacing wheel bearing, use new race provide with bearing. Do not mix up!

These wheel bearing rarely need replacing. If reusing wheel bearing do not mix-up side to side. Keep bearing with same race always.

Here is a bad wheel bearing that did need replacing.

View attachment 2576317

Should I put a little anti-freeze on this surface when installing the new rotor? And should I put Loctite on the bolts for bounding the router and hub?

I thought I am going to log my idiot work here.

I am an idiot when it comes to car repair. I broke things and makes matter worse.

so here it goes my attempt to do front rotors pads and bearing. I need all the wishes

I am sure there will be breakage along the way. I envision that snap ring will go haywire as I am attempting to do it without proper tooling. any other guess what else I will mess up?

Flange Gasket 43422 60070

Axle nut lock washer 90215-42025

Axle nut 54mm socket

Outer bearing 9008036067

Inner bearing 9008036098

Bearing seal 9031170011

Push washer 9021442030

I am equipped with chow cares you tube video

Thank you for the detailed post. I'm looking at doing the same in the next few months. Post like these make me even more secure in my recent LX purchase. The amount of detail and documentation is unparalleled on the Internet. Anyone paying those shop rates who owns a set of tools are fools. I get it, I have a good mechanic and he does great work, but he's old school and encourages me to do the things I can do myself. We have a wink and a nod system, it he says "you can't afford me on that one" it usually means do it yourself, it's a waste of your money. That's exactly what he said about this job and the non-functioning AC compressor. Raise a toast for the last few, honest mechanics out there! I'll drink to em and do this one myself!

Hi, I got a pair of new shiny rear brake calipers like yours, and I want to replace them when I do the new master assembly bleeding.You can drift those pins out with a punch....but yes, I'd be considering some re-manufactured calipers if all of them look like that one. I rebuilt mine....but I started with something not quite so degraded.

Stay after it.

View attachment 2598708

I am curious that should I paint the brake calipers? Is there any benefit of painting them?

- Thread starter

- #75

naah, I got one painted because the reman shop that rebuild these painted it red..

I think that brushed metallic that you have is the same or maybe better rust protection depends on how good of the rebuilder . Or is it new OEM?

where did you get yours?

mine was power stop from rock auto

I think that brushed metallic that you have is the same or maybe better rust protection depends on how good of the rebuilder . Or is it new OEM?

where did you get yours?

mine was power stop from rock auto

2001LC

SILVER Star

Sorry just saw this. No anti-size required no lock-tite, just torque to spec. I do like to add little marine grease around hob where rotor hole fits, after clean up. It's best to keep matting sure dry and free on grease.Should I put a little anti-freeze on this surface when installing the new rotor? And should I put Loctite on the bolts for bounding the router and hub?

View attachment 2633177

I did this job and made a video of doing it.

Hope it helps someone.

Nice job. and perhaps I missed a few things, as I jumped through video.

Spring scale is used to set breakaway preload as we torque adjusting nut (1st 54mm nut). If grease cold, we get a false preload reading. We need hub/grease/bearing above ~65F. I saw you check preload, after locking nut torque and was in 9.5-15LB range (spec). But with adjusting nut at only around ~5ft-lbf, you'd have way to loose wheel bearings. So ether you had adjusting nut tighter than I saw, or grease cold. They will start chattering/vibrating very soon, and score claw washer.

Also I did not see you check snap ring gap. Needs to be less than 0.20mm.

Best to use a new grease cap, if loose (easy to pond on), to prevent water entry.

Setting snap ring gap. Series 100 Toyota Land Cruiser 6 of 6

Used a "D" snap ring which is 2.4mm, factory stock is 2.2mm. Very important to settle grease at back of knuckle between axle brass bushing and front drive sh...

I'll play the cone game for a few minutes, if they don't break free right away, I use this stud extractor tool and pull them.

One minute of my time is worth more than the cost of a stud and cone. I throw studs and cones in in with other PS orders so shipping cost is mostly covered by the heavier items. I keep these in stock for when I might need them.

Plan ahead and make it easy on yourself.

One minute of my time is worth more than the cost of a stud and cone. I throw studs and cones in in with other PS orders so shipping cost is mostly covered by the heavier items. I keep these in stock for when I might need them.

Plan ahead and make it easy on yourself.

2001LC

SILVER Star

I hadn't though of using that, good idea. I once spent and hour on just one side. Found the cone washer and hub flange had been glued in.I'll play the cone game for a few minutes, if they don't break free right away, I use this stud extractor tool and pull them.

View attachment 2905450

One minute of my time is worth more than the cost of a stud and cone. I throw studs and cones in in with other PS orders so shipping cost is mostly covered by the heavier items. I keep these in stock for when I might need them.

Plan ahead and make it easy on yourself.

View attachment 2905446

These days I've a supper fast method. Kicks out cone washers, even ones glued in fast.

Last edited: