I watch movies on long trips on my head unit, so I'll take all the boom I can get.

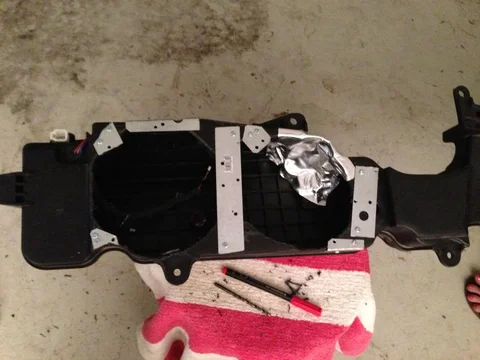

I'm sticking with two subs that are only 6.5 inches compared to the original 5 inch subs. That's only 30% more sub. I'm keeping some of the original port opening to some extent, so I really just need to find some extra port space and make sure I've accounted for anything I take from the original port. Two ports, in the corners, should do it.

Why do you think I need double the air space?

I'm sticking with two subs that are only 6.5 inches compared to the original 5 inch subs. That's only 30% more sub. I'm keeping some of the original port opening to some extent, so I really just need to find some extra port space and make sure I've accounted for anything I take from the original port. Two ports, in the corners, should do it.

Why do you think I need double the air space?