No problem gotta give a little back to those who give so much.

Flint what do you think of a fill hole at the fill level on the side of the case and a drain further down maybe on the bottom radi? That way you could fill the case like you do other things, when it's full it dribles out. Also drain it like your oil pan.

James

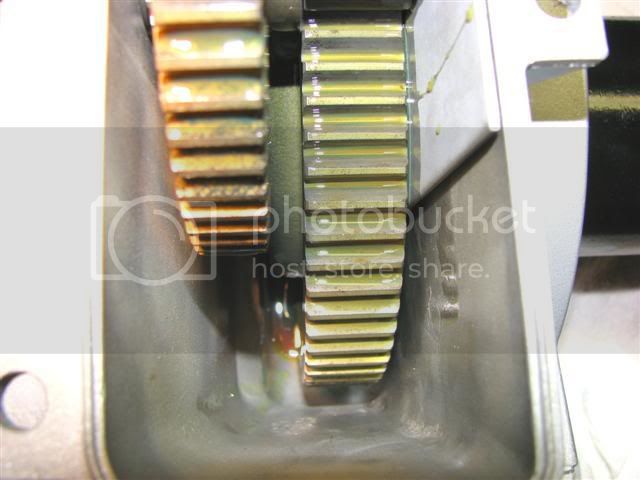

Unfortunately, we are somewhat limited as to where we can put the fill and drain plugs… owing largely to the arrangement of the gears inside the case.

I like your idea of having a fill hole at a point on the case that the lubricant spills out when at correct capacity.

The only problem is…. finding a place to put it. As you can see in the pic. below….the lower part of the case is heavily reinforced with ribbing limiting what we can do there.

We can’t go to the motor side for obvious reasons…and the front of the case would likely be covered by the mounting bracket… so we are left with only the clutch side to work with.

The level of the oil if filled per factory recommendations (6 fl. ozs), barely covers the bottom of the main gear. I fear that putting a hole that far down on the case (unless very small) would place it too close to the drain hole…thus weakening the case.

Here is a pic. looking straight down into the lower case with 6 ozs. of lube in it. As you can see, it is barely detectable.

At this level, leakage from the drum seal is highly unlikely because it just barely reaches the seal. I put a new seal in mine and about 12-14 ozs. of a mixture of Synthetic Gear Lube & Marvel Mystery Oil and have had no leaks.

Even if I develop a leak at a later date…the problem will be self correcting. It will simply leak down to the recommended level. Of course….this doesn’t take into account off camber angles your vehicle is subjected to, so additional oil loss is possible if you have a leaky seal.

Regardless of where you put your fill/drain holes and what size you choose…I would recommend that you stay away from any radius on the case, so as not to compromise its integrity. Aside from the reinforcing ribs, the radii are sources of strength.

My drain plug (while unsightly) allows me to place a 3/8" tube inside the fitting as soon as the cap comes off. This way I can drain the lube away without making much of a mess.

But, I'm sure there are at least a half dozen ways to do it.

Let us know what you come up with. I am always eager to learn.

Flint.