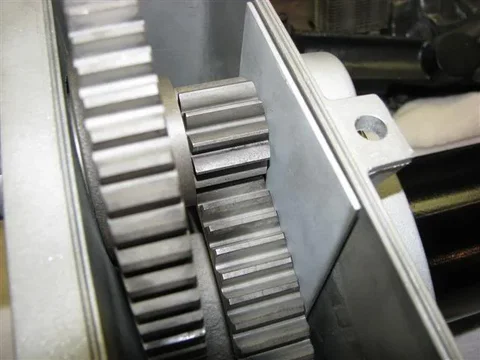

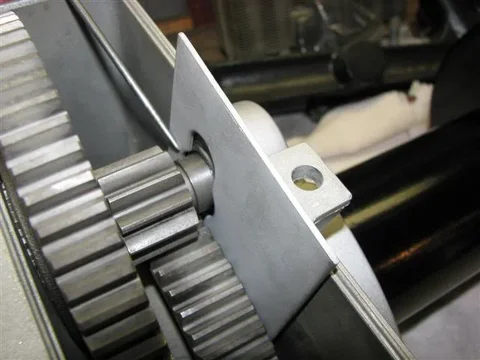

Warn 8274 Rebuild

I had to remove the gears in the upper housing do to rust. Has anyone been able to replace those needle bearings that fall out when you drive out the pin? I'd like to buy them somewhere if possible as opposed to buying the entire housing kit from Warn.

I had to remove the gears in the upper housing do to rust. Has anyone been able to replace those needle bearings that fall out when you drive out the pin? I'd like to buy them somewhere if possible as opposed to buying the entire housing kit from Warn.