DanS HJ-45

SILVER Star

- Thread starter

- #101

Sure, it looks ok....but boy would it look outstanding in a 40....say an LX, perhaps.

Man, that was a good try.

Too late though, we tightened the nuts and bolts and everything.

Dan

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

Sure, it looks ok....but boy would it look outstanding in a 40....say an LX, perhaps.

DanS HJ-45 said:Man, that was a good try.

Too late though, we tightened the nuts and bolts and everything.

Dan

Wow.

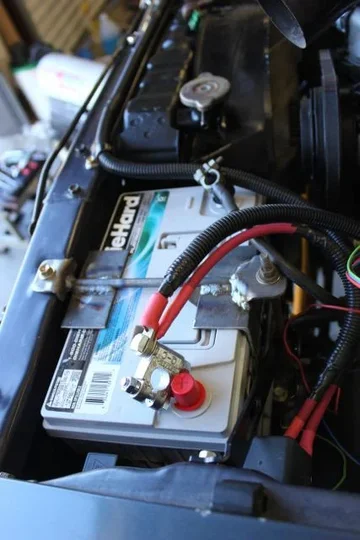

As always, Casa Silbaugh does epic work.

And the fact I can be the "parts fairy" makes me especially happy.

Hey Dan, luv you quote about Aussies don't use coolant, only water.

So in true Aussie fashion "what a load of cocky crap"

Keep up the good work mate

I think it all depends on where and what the cruiser was used for. All our 3 cars are filled with coolant (pictorial proof available on request), but again, if a machine was low on water on the farm, we'd just wack in the nearest water and call it done.

I'll take my camera to Supercheap and catch a buyer, old days yes, these days nothing but coolant

Ok enough blah blah...get this thing fired up

DanS HJ-45 said:Trying!

I am busy with work until sometime friday, when I will hopefully make it back to the shop for a few solid days of wrenching/soldering to get it done.

But we shall see. I have a bad feeling that some work related stuff will pop up that will take a lot of my free time away for a month or two.

Dan

Get busy ya slack prick. Lazy, lazy, lazy.