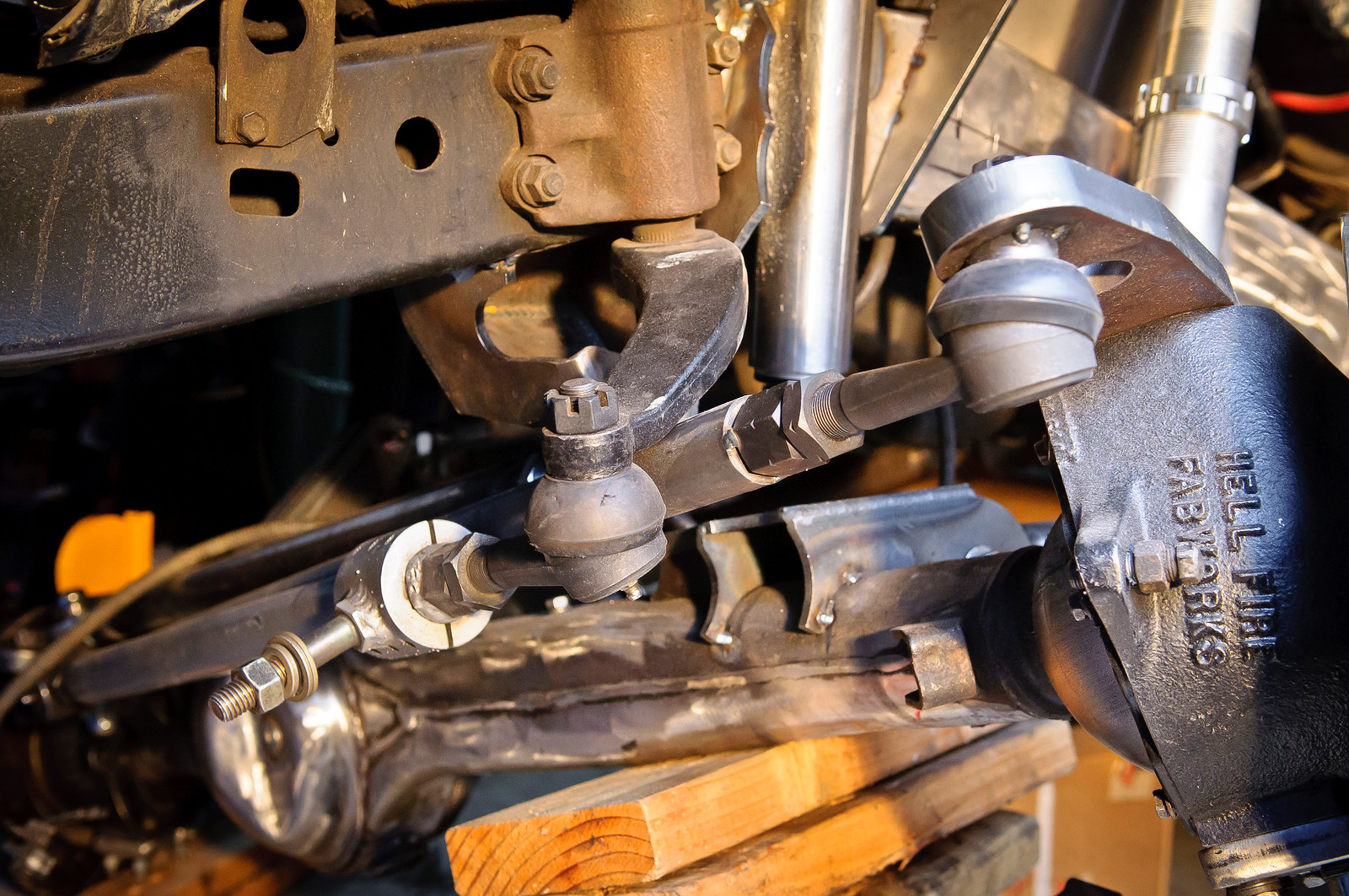

EMF Tie Rod Ends just got better! Do you have an application that requires a straight bolt to go through? No problem!! We took out the tapered pin and developed a straight "Hat Pin" as we like to call it. Eliminating the need for a separate bolt, the Hat Pin incorporates a 3/4" straight Pin which takes the place of the bolt, giving it total strength built all into one. The "hat" gives some space between the mounting surface and the joint to allow maximum deflection.

THIS IS A HIGH-DEFLECTION PIN USED FOR DRAGLINK APPLICATIONS (KNUCKLE TO STEERING BOX). This specific 3/4" High Deflection pin has a deflection rate of 29 degrees one way, making the total amount of deflection 58 degrees.

Available in a 7/8"-14 Shank (Heim Joint Thread), a 7/8"-18 Shank (Tie Rod End Thread), or a 1.0"-18 TPI - Left-hand and Right-Hand threads available and features a 3/4" straight pin. All components of our Tie Rod Ends are made in house from a billet 4140 Chromoly and coated with zinc, aside from the pins which are coated with a black liquid nitride to ensure the best possible wear and corrosion resistance. You should be able to go many years without needing to replace any of the internal components. Unlike any other Tie Rod End on the market, EMF's TRE's are serviceable, greaseable and REBUILDABLE. If you ever start to feel a little slop in the joint, you just tighten the cap. If you ever have to replace the inner components, you just have to buy a rebuild kit!

All EMF Joints are available with our Patent-Pending Technology that will ensure all inner components of any of our EMF Tie Rod Ends, Rod Ends or Ball Sockets will remain in place, thus, not allowing the back locking cap to loosen. ** Added pressure and friction on the joint will generally cause the cap to back off, resulting in play within the joint and wear on the internal components - We have solved this issue. See our Friction Testing video Even if the set screw and threaded cap back out completely during your trail ride, you can still run with the joint in place and not have to worry about the inner components coming loose - which ensures you have time to get back to camp without having to make a trail fix. It also ensures that you have a longer wear of your components because it reduces the ability of the joint to have premature play.

or guys that run a shop doing bends all day

or guys that run a shop doing bends all day