Ok plucked up courage to go for the Central Diff Lock motor.

Dropped the central diff with aid of jack. It did not come down as far as I thought so still a bit of a wiggle to get the CDL motor out.

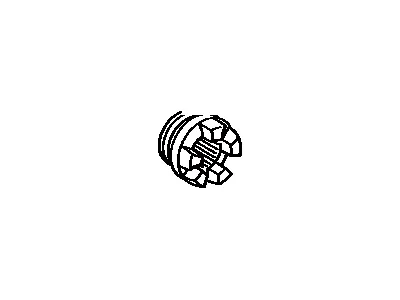

So after getting into the unit and only breaking one screw bolt head off (so more corrective action needed) here are pics of what greeted me.

Ugly EH?!

So the good news is that the contact makers and breakers were ok.

The motor winding is burnt out and a consequence of that is that the plastic that partly mounts the brush holders has melted. This means the brushes are fixed in.

So I will be off to have motor rewound and brush holders repaired.

Now the real issue is that the breather connection pipe which is plastic is broken off so the breather pipe cannot connect. I'll have to figure out a fix for that. Here is a pic or two for you.

You can see the hole on top pic and the little area that looks like it is sticking out but it is not as it is moulded on the other side - otherwise it would be easy to re attach the breather pipe. No such luck.

Looks like I can drill the hole wider and insert/glue a tube so that it sticks out and I can re-attach the breather tube. was thinking that some old cleaned out ball pen ink tubing might work metal/plastic and will glue easily with super glue. Not sure yet.

Now while I was under there I could feel the cog that turns to engage lock position. And according to all advice I must put the motor back with both central diff and motor in locked positions. I could not turn the cog by hand.

Any advice??

regards Chalky

my official 1999 Electrical Wiring Diagram manual arrived all the way from JFK.

my official 1999 Electrical Wiring Diagram manual arrived all the way from JFK.