You have no idea. Sitting on an apple crate in the tub on a stand off the frame, with a disconnected steering wheel in my hands, making motor noises. It's embarrassing but its all I have.

I work when I get the time and I've tried to do work in a project type basis but is does come out chaotic and random. Both the axles are done, all painted up with new knuckle bearings in front and wheel bearings in the back, new springs and brake pads and shoes. The top is done as well, painted with the headliner installed. And there is a few parted painted 854 blue.

Currently I am working on the tcase, trans and motor. The tcase and trans were just a matter of cleaning and painting. I got a master gasket set for the small block since everything including the rear main would probably leak oil like a sieve. I wasn't planning on using the head gaskets since the motor is fairly low mileage since overhaul but I noticed corrosion around the front coolant crossover in the intake gasket. Ok, ok, do the head gaskets. Turned out the head gaskets were fine but I found 2 chipped push rods so it wasn't a wasted effort.

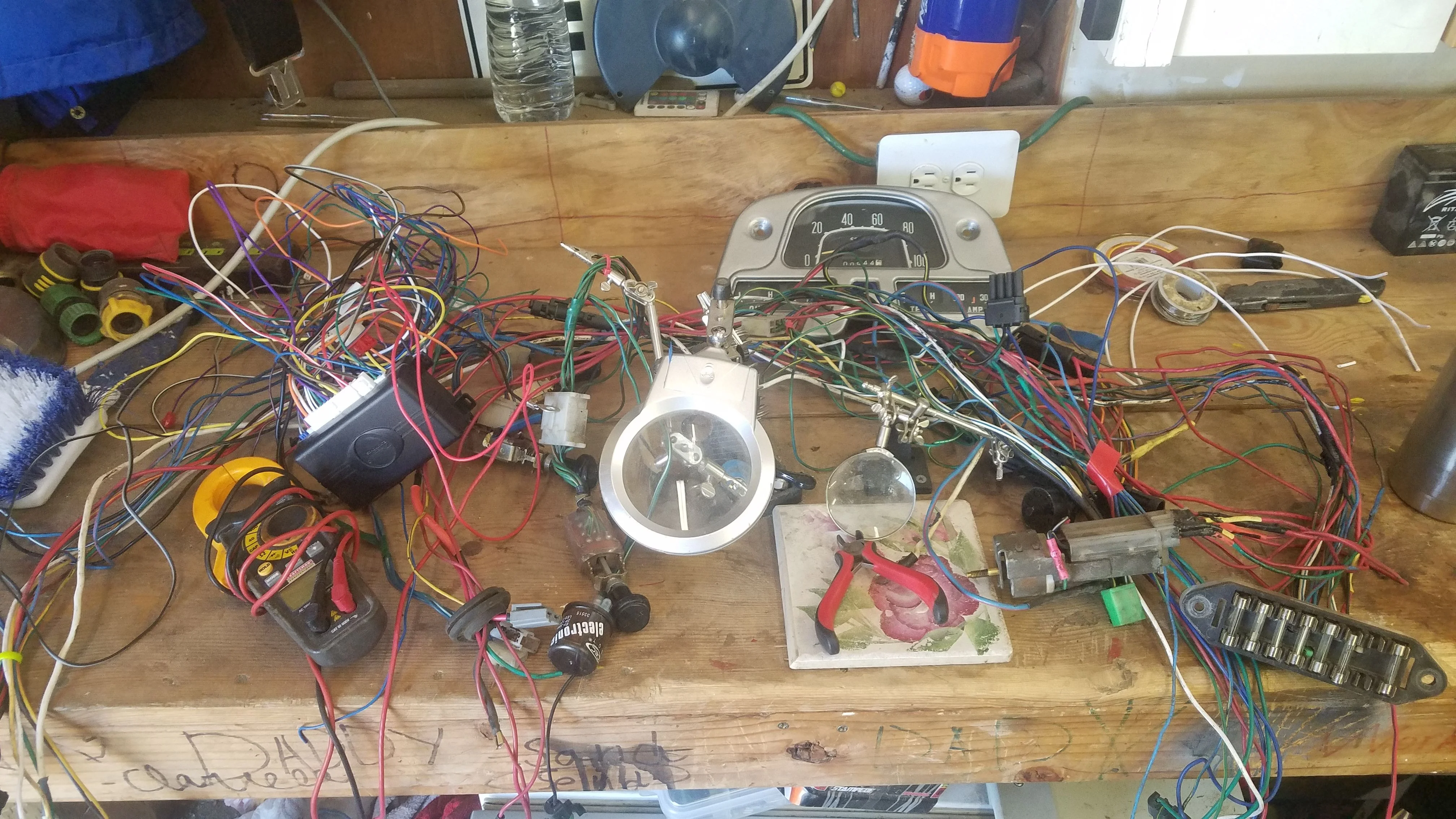

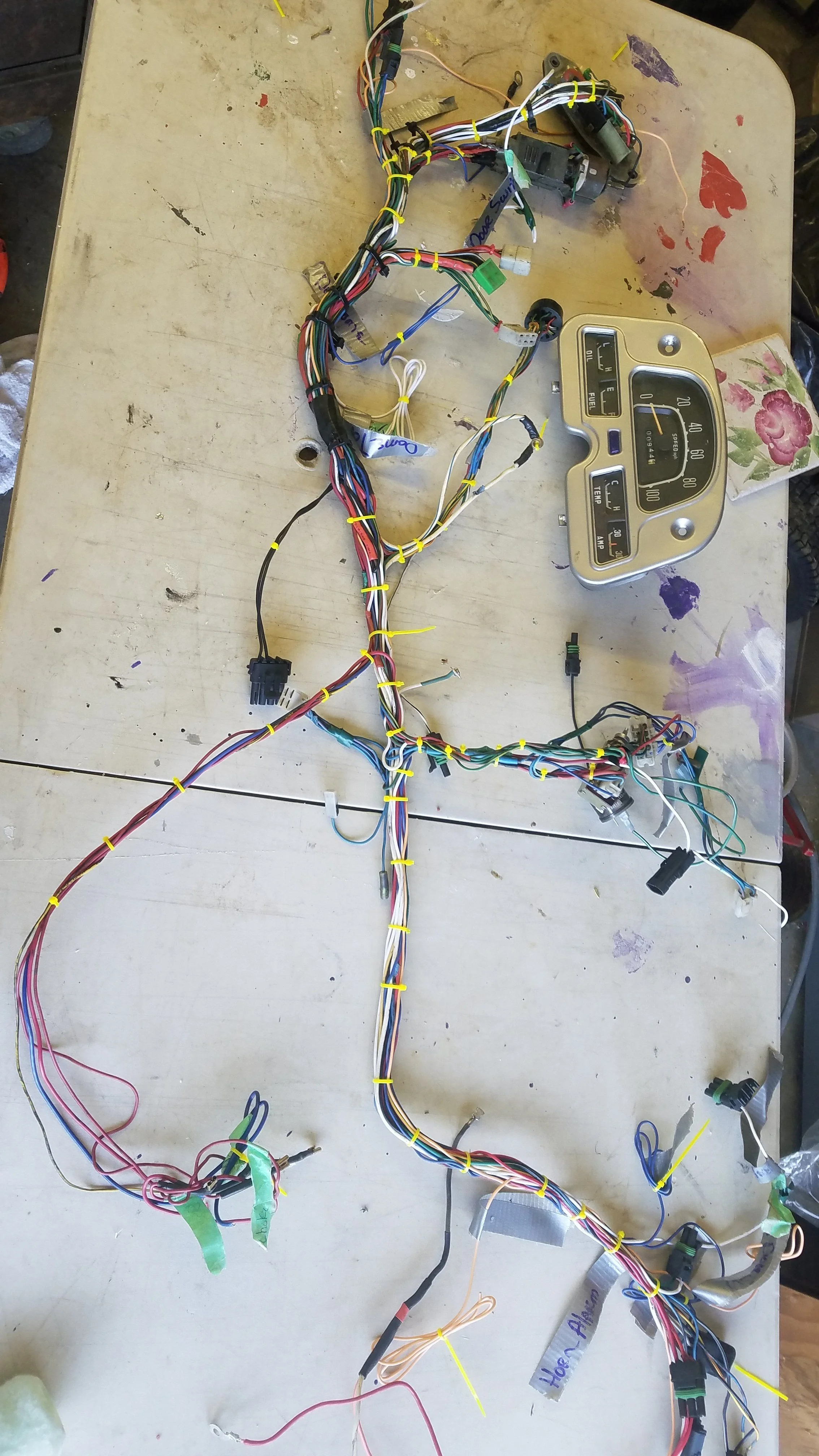

I've decided anything with a seal it in gets replaced so I have a new water pump, fuel pump, the vacuum advance leaks so one of the fancy new distributors, I kitted the quadrajet recently and last time I ran it, it worked fine. I bent one of the old crusty valve covers lifting the motor out, the front cover had the timing mark bent (making timing it an educated guess) and the oil pan drain plug is stripped. My tracking number says replacements for all 3 are out for delivery today. Soon as it gets the new skin, I'll primer, paint it and bolt the big pieces back together.

The trans and tcase in primer a couple of days ago. Its now coated with high temp GM corporate blue.

The top is visible in background of the pic above. Its supposed to be Cygnus white. Or its as close to the secret recipe that I could get to.

I painted the bezel the same as the top.

Axles were one of the first things I tackled on a project basis.

Painting little parts is an endless task. Or it seem so. Or I'm wayyyy too anal about this stuff.