sleeoffroad

Supporting Vendor

I'm not being argumentative, Christo, since we all know the level of expertise I have (edited: if it wasn't evident, in humor), but think there's a sliding scale on value perception.

Added smiley faces for you

Personally, if I could've replaced the housing for double the amount I spent on the cobble-a-thon double, double cardan, I'd have considered it worth the cost and effort, if it were the end all to the great caster debate.

The problem is that you need to get the pinion angle and caster spot on. Not an easy process, and impossible to do with a pre-fab housing that all done at the manufacturer. We did that when we built the White Rhino and the Blueberry. We used a Diamond housing, set it all up with correct pinion angle / caster, then verified with caster sweep and then final welded. Not going to work for the average DIY.

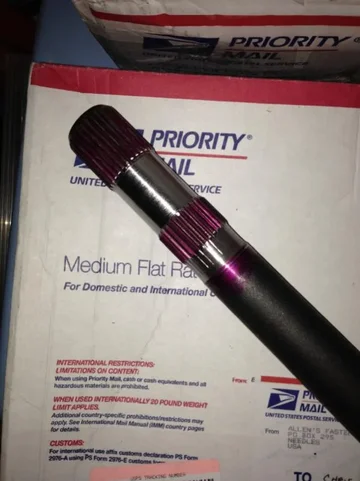

This is how we set the caster

So a prefab housing would be nice, but you can not do a one fits all housing.

Plus, I wouldn't be faced with trying to cobble hydro through the cobbled arms.

Bandaid, upon bandaid, upon bandaid, in my case.

Hydro is always an issue to fit. Doesn't matter where you fit it. We did it on the drag-link on the Blueberry and it worked decently.

PS, this last photo was taken on day 5 of the Ultimate Adventure. This is not how you want to see your truck. Broke the front diff fdr the 2nd time on the trip, as well as one of the rear axle shafts. Stupid thing twisted due to E-locker and we had to cut the actuator fork apart to get it out. We had to leave the trail with 1 wheel drive. We replaced the ring and pinion in the front twice in 5 days.

And the rust, that was from 1 day in the mud at General Sams off-road park. That was some nasty stuff. The truck was on 40" tires with 7 " of lift and the mud was up to the hood.

Last edited: