- Thread starter

- #21

I'm not doubting the validity of the theory.

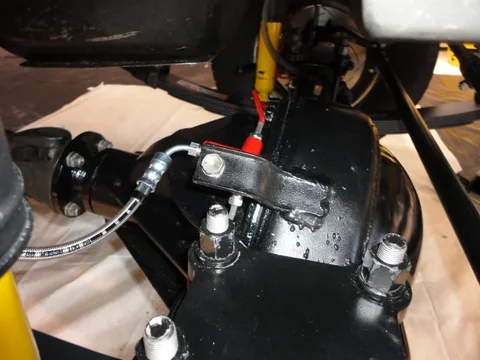

The hose they used on these is labeled DOT-GY-03/13-1/8-HL

Is this 1/8" hose? Is this the right or wrong hose given what you have said?

And again: given the 20" length of each hose is this something that will make any discernible difference (when compared to stock hoses)?

The hose they used on these is labeled DOT-GY-03/13-1/8-HL

Is this 1/8" hose? Is this the right or wrong hose given what you have said?

And again: given the 20" length of each hose is this something that will make any discernible difference (when compared to stock hoses)?