Do you have an aftermarket coolant temp gauge?Yeah I just replaced it last year with an OEM unit so was hoping it wasn’t the culprit. I also replace a sensor when I did it, but looking back I can’t remember which one.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Registry 3FE Owners Check-In

- Thread starter alkaline747trio

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?I’m gonna go out in the limb and say its the water temp sender off the theromstat housing, the back wire tends to get real corroded. Make sure u replace with OEM or a used OEM that works. Aftermarket will give you these symptoms, at least my autozone one did, but it would go above the middle mark and back down again, multiple times a day. And burp ur system by driving the front right tire onto a ramp and let her cool down overnight, then top off the resevour.

Last edited:

Get an aftermarket temp gauge and never have to worry about the stock idiot gauge anymore...I’m gonna go out in the limb and say its the water temp sender off the theromstat housing, the back wire tends to get real corroded. Make sure u replace with OEM or a used OEM that works. Aftermarket will give you these symptoms, at least my autozone one did, but it would go above the middle mark and back down again, multiple times a day.

Coolant and tranny temp is all you need.,,

I looked up my receipt from Partsouq- replaced the temp sensor 8942220010 and thermostat at the same time. I’m thinking it’s probably the wire like was mentioned.

Marco- I’ll have to dig into the aftermarket solution at some point, right now I’m trying to get this thing baselined. Feel free to drop any links or products that would be good to research them.

Marco- I’ll have to dig into the aftermarket solution at some point, right now I’m trying to get this thing baselined. Feel free to drop any links or products that would be good to research them.

You are on the right track. My advise is to add a digital or analogue aftermarket coolant temp gauge ASAP. Kill 2 birds w/ 1 stone while you baseline your cooling system, etc.I looked up my receipt from Partsouq- replaced the temp sensor 8942220010 and thermostat at the same time. I’m thinking it’s probably the wire like was mentioned.

Marco- I’ll have to dig into the aftermarket solution at some point, right now I’m trying to get this thing baselined. Feel free to drop any links or products that would be good to research them.

I had no idea removing a radiator from the ol fj80 was such a job…. More than half way done and I’m whooped.

I am really curious about this. I am semi skilled mechanic. I but not never really broke into transfer cases or transmissions. I have been looking into re-gearing and the hi gear seemed like a better option rather then doing the diffs right now. Long story short.I am kind of in the budget camp- but I still went for 33” tires. I did the T-case regear (hi gear under drive and low low gear)and it made a big difference.

I actually did it first on 31s and felt a big difference and then again felt the rig get peppier when I went to 33s.

T Case regear was the cheaper option rather than do differentials.

Also I was able to do the whole job myself.

Again my aim isn’t a rock crawling machine but a capable and good looking rig that doesn’t cost me $20k

What has your experience been on the highway with it?

Do you have any information or references or guides?

Is there lash issues and shimming like a diff?

etc

Any information would be helpful. I appreciate.

Been looking everywhere.

I have had my 91 for 8 yrs now, it was bone stock when i picked her up, then 33s, 35s w/ 4.10. 35s w/ 4.88, 37s w/ 4.88, and now 37s w/ 4.88 and high/low range underdrive. To be honest, it pulls much harder and faster now w/ 37s than it was stock. It will keep up with 1FZs on highway and steep grades w/ lots of skinny pedals and the downside is that you will burn more fuel doing it. However, with the 4.88 and high range underdrive equates to around 5.38 allows it to be in within the powerband @ 70-75mph, 2700rpm effectively keeps my rig in OD without having to downshift to 3rd all the time and increase fuel efficiency. BTW, my rig is desmogged and also has a Nomad Wholesale valve body upgrade in the A440F, so that also helps tremendously with the performance.I am really curious about this. I am semi skilled mechanic. I but not never really broke into transfer cases or transmissions. I have been looking into re-gearing and the hi gear seemed like a better option rather then doing the diffs right now. Long story short.

What has your experience been on the highway with it?

Do you have any information or references or guides?

Is there lash issues and shimming like a diff?

etc

Any information would be helpful. I appreciate.

Been looking everywhere.

CHeers.

hello ,

since becoming a 3FE owner operator myself now as of recent , i have been working of a few new and unique 3FE .........

lets just say little problem solvers kits ...

- if anyone has a suggestion for the 3FE anything suggestion box feel free ...

kindly

matt

since becoming a 3FE owner operator myself now as of recent , i have been working of a few new and unique 3FE .........

lets just say little problem solvers kits ...

- if anyone has a suggestion for the 3FE anything suggestion box feel free ...

kindly

matt

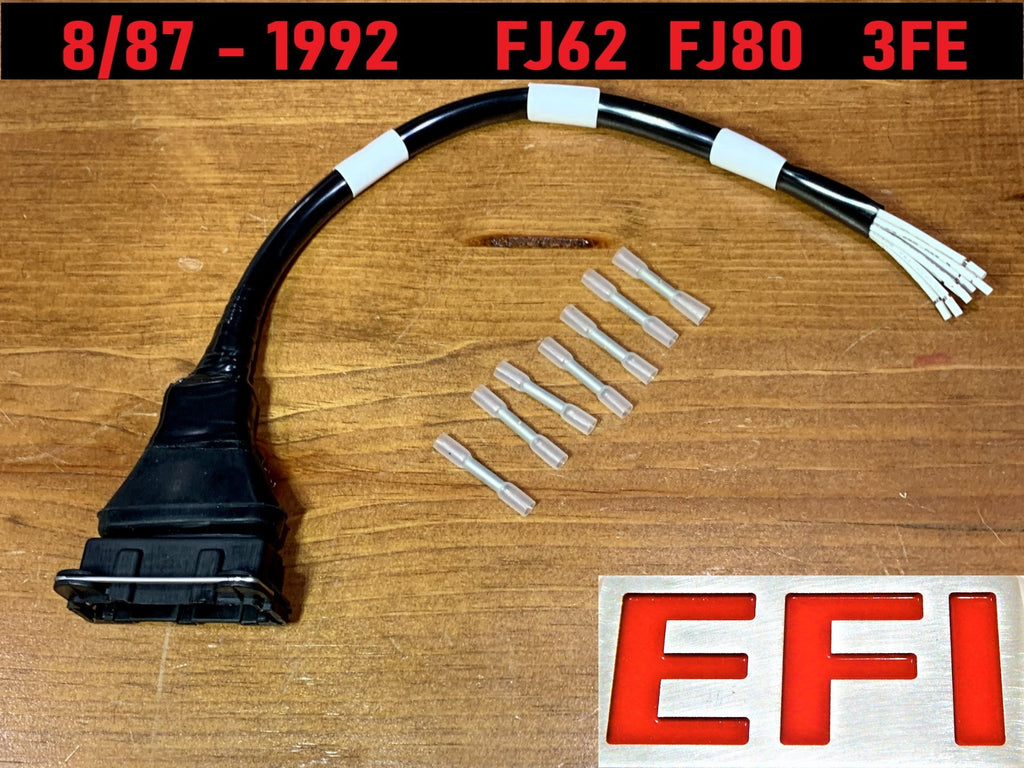

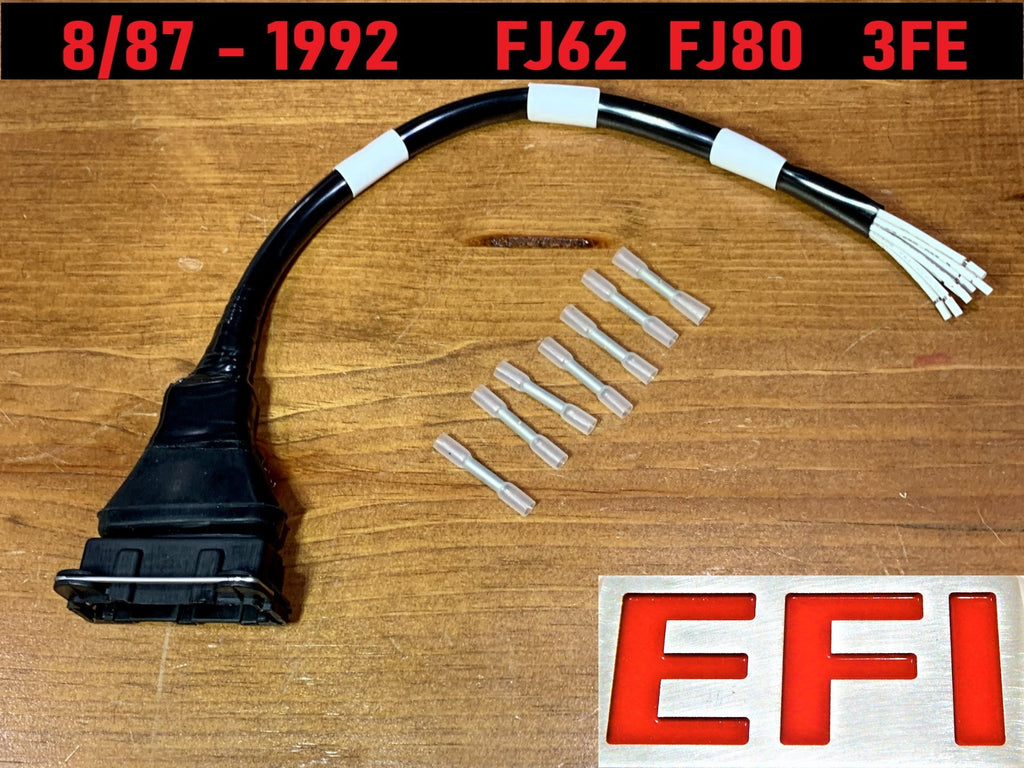

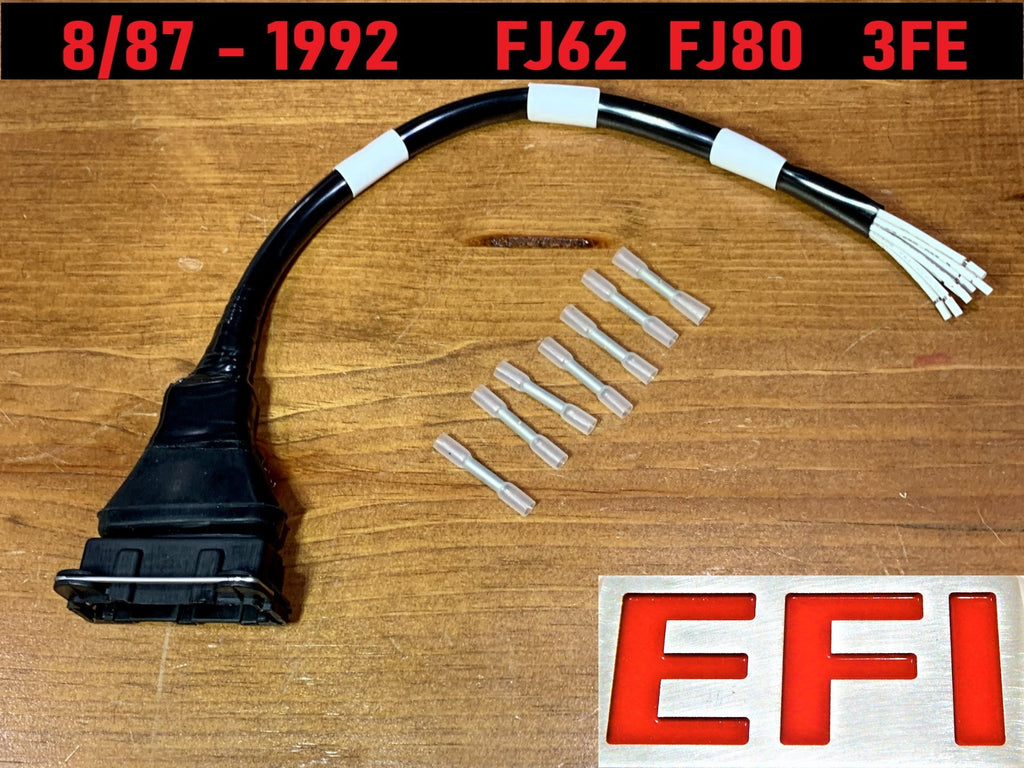

FJ62 / FJ80 3FE MAF AIR FLOW METER Repair Connector Plug Harness Side Kit Comes With 3M Marine Grade Heat Shrink Butt Connectors Also - VintageTEqParts.com

- MAF - FJ62 / FJ80 - 3FE - ALL WEATHER SNOW - VERSION RUBBER BOOT Incorporated into this design -...

vintageteqparts.com

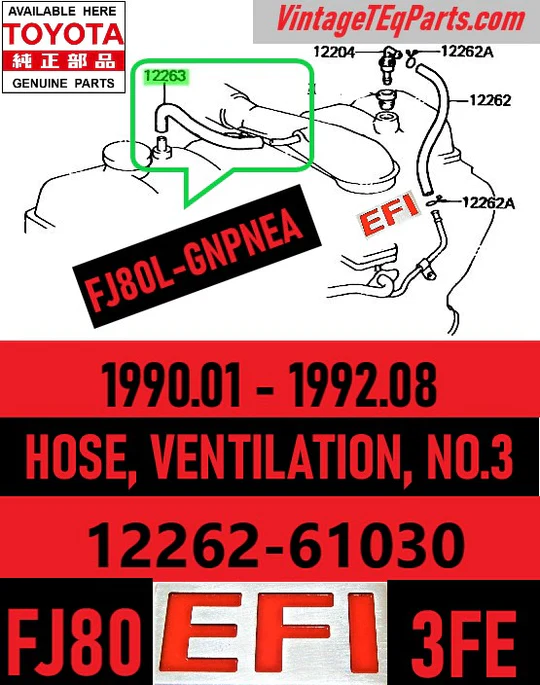

FJ80 3FE OEM TOYOTA Genuine Parts Breather Hose Valve Cover to Air Intake Ventilation Crankcase PCV 12262-61030 Fits 1/90-8/92 FJ80 KIT Comes w/ 2 OEM Yellow Zinc Clamps - VintageTEqParts.com

- FJ80 3FE Toyota OEM JAPAN Spec. Parts Breather Hose - 100% TOYOTA GENUINE Parts - Valve Cover to Air Intake...

vintageteqparts.com

3F 3FE FJ62 FJ80 OEM TOYOTA YAZAKI Alternator Repair Plug Connector Kit 3F-E 3 WIRE Round Plug Type Includes Seal Grommets & Extra Terminals - VintageTEqParts.com

3F 3FE 3F-E FJ62 FJ80 OEM TOYOTA YAZAKI Alternator Repair Plug Connector Kit 3 WIRE Round Plug Type Includes Seal...

vintageteqparts.com

Alternator Install and Mounting Kit 100% Toyota Genuine Parts F , F1.5 , 2F 3F 3FE Adjustment Feature Restoration & Needed Repairs Kit 1962-1992 FJ40, FJ55, FJ60, FJ62, FJ80 - VintageTEqParts.com

- - Alternator Install and Mounting Kit - 100% Toyota Genuine Parts - F , F1.5 , 2F...

vintageteqparts.com

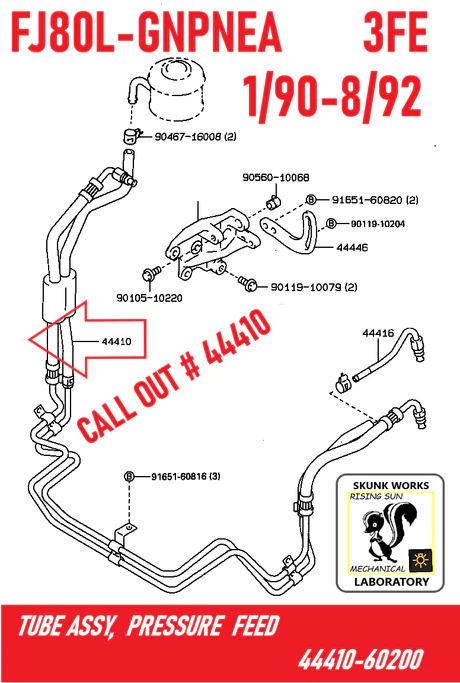

FJ80 3FE High Pressure Power Steering P/S LINE HOSE TUBE Feed 1/90 - 8/92 - VintageTEqParts.com

FJ80 3FE High Pressure Power Steering LINE HOSE TUBE Feed P/S Fits 1/90 - 8/92 FJ80L-GNPNEA - SPECIALTY MADE...

vintageteqparts.com

Last edited:

Does anyone have a link/source to buy a genuine Toyota OEM accelerator cable for a 1992 80 series 3FE?

Bonus points for a few pics showing the accelerator linkage routing under the hood.

TIA

Bonus points for a few pics showing the accelerator linkage routing under the hood.

TIA

if I’m remembering right OEM was discontinued, at least from the cruise control to the TB. I know there was conversation in this thread about it, I think I posted a picture too.

since becoming a 3FE owner operator myself now as of recent , i have been working of a few new and unique 3FE .........

lets just problem solvers kits ...

- if anyone has a suggestion for the 3FE anything suggestion box feel free ...

kindly

matt

FJ62 / FJ80 3FE MAF AIR FLOW METER Repair Connector Plug Harness Side Kit Comes With 3M Marine Grade Heat Shrink Butt Connectors Also - VintageTEqParts.com

- MAF - FJ62 / FJ80 - 3FE - ALL WEATHER SNOW - VERSION RUBBER BOOT Incorporated into this design -...vintageteqparts.com

View attachment 3185645

FJ80 3FE OEM TOYOTA Genuine Parts Breather Hose Valve Cover to Air Intake Ventilation Crankcase PCV 12262-61030 Fits 1/90-8/92 FJ80 KIT Comes w/ 2 OEM Yellow Zinc Clamps - VintageTEqParts.com

- FJ80 3FE Toyota OEM JAPAN Spec. Parts Breather Hose - 100% TOYOTA GENUINE Parts - Valve Cover to Air Intake...vintageteqparts.com

View attachment 3185647

3F 3FE FJ62 FJ80 OEM TOYOTA YAZAKI Alternator Repair Plug Connector Kit 3F-E 3 WIRE Round Plug Type Includes Seal Grommets & Extra Terminals - VintageTEqParts.com

3F 3FE 3F-E FJ62 FJ80 OEM TOYOTA YAZAKI Alternator Repair Plug Connector Kit 3 WIRE Round Plug Type Includes Seal...vintageteqparts.com

View attachment 3185648

Alternator Install and Mounting Kit 100% Toyota Genuine Parts F , F1.5 , 2F 3F 3FE Adjustment Feature Restoration & Needed Repairs Kit 1962-1992 FJ40, FJ55, FJ60, FJ62, FJ80 - VintageTEqParts.com

- - Alternator Install and Mounting Kit - 100% Toyota Genuine Parts - F , F1.5 , 2F...vintageteqparts.com

View attachment 3185649

FJ80 3FE High Pressure Power Steering P/S LINE HOSE TUBE Feed 1/90 - 8/92 - VintageTEqParts.com

FJ80 3FE High Pressure Power Steering LINE HOSE TUBE Feed P/S Fits 1/90 - 8/92 FJ80L-GNPNEA - SPECIALTY MADE...vintageteqparts.com

View attachment 3185650

Matt, a bracket to handle the 90A alternators would be peachy. I mangled one of mine with a grinder to allow juuuust enough room to get the belt to tension, but either a block with proper angling (to go between the motor and the bracket) or a longer bracket would both be great.

Matt, a bracket to handle the 90A alternators would be peachy. I mangled one of mine with a grinder to allow juuuust enough room to get the belt to tension, but either a block with proper angling (to go between the motor and the bracket) or a longer bracket would both be great.

i have observed this topic being discussed many many times in my mud life ,

i have never ever seen a single TECH Photo or video on the topic ?

- i offer a industrial version Genuine NipponDenso 90A External Fan unit , also the OEM internal FAN unit for a 3FE

i know the bottom pivot tabs spacing is different ?

- why does the external fan unit work all years 3FE and the internal fan unit only some years 3FE is how i understand this to be a issue ?

GENUINE NipponDenso / DENSO 90A amp 12V Alternator Comes With B+ OEM RING Terminal Rubber DENSO Boot and Pigtail , Also Special HEX NUT Fits 1/90-7/92 FJ80 3FE Part # Part # 27060-61100 - VintageTEqParts.com

- NOS GENUINE NipponDenso / DENSO - Part # 27060-61100 / 27060-61100-84 - 90A amp NOS 12V Alternator - Comes...

vintageteqparts.com

OEM Genuine NipponDenso / DENSO Japam Spec. Alternator 90A amps 1988-1992 FJ62 FJ80 3FE 3F Carb - VintageTEqParts.com

NO CORE REQUIRED ! MADE IN JAPAN GENUINE OEM NipponDenso / DENSO Alternator 90A amps MADE IN JAPAN 1988-1992 FJ62 FJ80 3FE ...

vintageteqparts.com

Last edited:

do you offer the 90 amp bracket for the 80 amp users who wants to convert to 90 amp unit?i have observed this topic being discussed many many times in my mud life ,

i have never ever seen a single TECH Photo or video on the topic ?

- i offer a industrial version Genuine NipponDenso 90A External Fan unit , also the OEM internal FAN unit for a 3FE

i know the bottom pivot tabs spacing is different ?

- why does the external fan unit work all years 3FE and the internal fan unit only some years 3FE is how i understand this to be a issue ?

GENUINE NipponDenso / DENSO 90A amp 12V Alternator Comes With B+ OEM RING Terminal Rubber DENSO Boot and Pigtail , Also Special HEX NUT Fits 1/90-7/92 FJ80 3FE Part # Part # 27060-61100 - VintageTEqParts.com

- NOS GENUINE NipponDenso / DENSO - Part # 27060-61100 / 27060-61100-84 - 90A amp NOS 12V Alternator - Comes...vintageteqparts.com

OEM Genuine NipponDenso / DENSO Japam Spec. Alternator 90A amps 1988-1992 FJ62 FJ80 3FE 3F Carb - VintageTEqParts.com

NO CORE REQUIRED ! MADE IN JAPAN GENUINE OEM NipponDenso / DENSO Alternator 90A amps MADE IN JAPAN 1988-1992 FJ62 FJ80 3FE ...vintageteqparts.com

View attachment 3186319

View attachment 3186320

not yet

its on the board now for sure !

my 90 amp external fan unit has the wider spacing between the tabs

fyi ...

its on the board now for sure !

my 90 amp external fan unit has the wider spacing between the tabs

fyi ...

@ToyotaMatt this the use case I meant: 90A alt in an 80A truck.do you offer the 90 amp bracket for the 80 amp users who wants to convert to 90 amp unit?

Grinding the motor mount with an angle grinder, in place, isn't difficult:

I see I'm a bit late to answer you in realtime, but I'm replacing my alternator too.

I'm modding my 80A bracket per 3FE 90 amp alternator sanity check - https://forum.ih8mud.com/threads/3fe-90-amp-alternator-sanity-check.1020821/post-11324130.

The discussion in that thread begins at 3FE 90 amp alternator sanity check - https://forum.ih8mud.com/threads/3fe-90-amp-alternator-sanity-check.1020821/post-11323004.

But the different tab/ear location starts you very close the extreme end of adjustment range on the 80A bracket, as seen in this photo:

Actually it's installed and works great and I saved enough money to buy about 50 gallons of gas but thanks for all your support!

and the difference (another inch of throw?) in this one:

3FE 90 Amp upgrade, round 2, son of a

So I have the $21.07 bracket from the dealer, this bracket is for the 90 amp alternator, and the part number is 16381-61060. As you can see from the first pictures, the bracket is slightly different from the original one used with the 80 amp alt. However, I still could not get the 90 amp alternator to fit at the lower mounting point. This mounting point is part of the DS engine mount, so is there also a different engine mount used for the 90 amp?

Has anyone successfully bolted on the 90 amp(part number 27060-61100-84) without grinding the alt. to fit? Try as I might, I couldn't find the hole and get the bolt in. In the end I just put the 18 year old cruddy 80 amp alt back in and put everything back together. I think when I try to replace the water pump, I'll give the new alt. another try, since there will be a lot more room to work in and inspect/see whats going on, and where to grind.

Anyone do the 90 amp upgrade without grinding?

3FE powwa

View attachment 409610View attachment 409611View attachment 409612

The 90A bracket (16381-61060) being NLA:

16381-61060 - Mount Bar Adjust Bracket 1991-1992 Toyota Land Cruiser | Ourisman Toyota Parts

Save Money On Your Mount Bar Adjust Bracket (1638161060) For Your 1991-1992 Toyota Land Cruiser When You Shop With Ourisman Toyota Parts!

16381-61060 - Toyota Parts Deal

You have the 80A one circled in this image, on your site:

https://cdn.shopify.com/s/files/1/0064/9216/0085/products/3FECooling1_900x.jpg?v=1622581953

You seem to have magical powers of finding sources for NLA Toyota parts, so my suggestion box submission is that this one would be helpful for those of us whose 80A alts die and need to move to 90A.

Does anyone have a link/source to buy a genuine Toyota OEM accelerator cable for a 1992 80 series 3FE?

Bonus points for a few pics showing the accelerator linkage routing under the hood.

TIA

I was Mia-remembering what cable was NLA, it’s the one from the cruise box to the TB.

3FE Cruise Control Cable Solution?

forum.ih8mud.com

forum.ih8mud.com

@ToyotaMatt this the use case I meant: 90A alt in an 80A truck.

Grinding the motor mount with an angle grinder, in place, isn't difficult:

But the different tab/ear location starts you very close the extreme end of adjustment range on the 80A bracket, as seen in this photo:

and the difference (another inch of throw?) in this one:

The 90A bracket (16381-61060) being NLA:

16381-61060 - Mount Bar Adjust Bracket 1991-1992 Toyota Land Cruiser | Ourisman Toyota Parts

Save Money On Your Mount Bar Adjust Bracket (1638161060) For Your 1991-1992 Toyota Land Cruiser When You Shop With Ourisman Toyota Parts!toyotaparts.mcgeorgetoyota.com

16381-61060 - Toyota Parts Deal

www.toyotapartsdeal.com

You have the 80A one circled in this image, on your site:

https://cdn.shopify.com/s/files/1/0064/9216/0085/products/3FECooling1_900x.jpg?v=1622581953

You seem to have magical powers of finding sources for NLA Toyota parts, so my suggestion box submission is that this one would be helpful for those of us whose 80A alts die and need to move to 90A.

i will admit to not fully understanding this topic in it's entirety , as i have a 10/88 FJ62LG-PNEK 3FE ......

but know about it in a general way as being a issue requiring a grinder to allow proper fitment of the internal fan 3FE alternator that is actually still available at your local Toyota dealer by Special Order means .......

- is this one part the simple solution bolt on problem solver ?

- or we are talking grinding away at the cast iron lower PIVOT bracket for the 2 lower tabs on the internal fan unit install ?

- or both ?

Thanks very much for the pics, those will help!View attachment 3186975View attachment 3186974

I was Mia-remembering what cable was NLA, it’s the one from the cruise box to the TB.

3FE Cruise Control Cable Solution?

forum.ih8mud.com

Thanks very much for the pics, those will help!

what is the issue exactly with your current cable ?

Similar threads

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)