Is the front driveshaft double cardan?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3 Link Questions

- Thread starter VCCruzr

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?- Thread starter

- #82

Is the front driveshaft double cardan?

Negative.

I don't believe either are an accurate depiction of the OE configuration, but here's what little I do know.

Disregard all verbiage in the first pic. It doesn't depict a "broken back" configuration, nor an accurate depiction of the OE geometry.

The first pic should require a DC shaft, based on any info you'll find on High Angles or Tom Wood's web pages, or billa vista's PBB dissertations. Point the diff at the TC and it's a DC shaft.

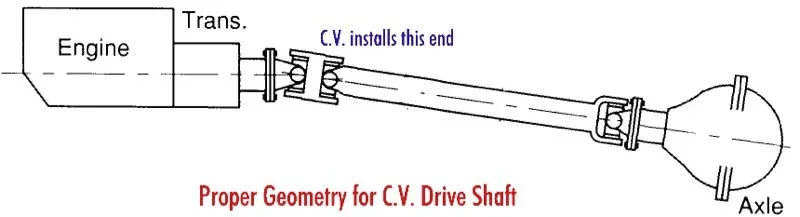

The second pic is the proper geometry for a standard drive shaft (meaning no CV joints) as long as the flanges are perfectly parallel ( think a margin of. 1-2 degrees is stated acceptable)

Thing is, especially with a 3-link, I'd think caster would trump driveline angle, unless cutting the knuckle balls off and turning the entire housing. If cutting and turning, guess the options there for either, but the flanges parallel is the same as the rear and shouldn't require a CV jointed DS.

Disregard all verbiage in the first pic. It doesn't depict a "broken back" configuration, nor an accurate depiction of the OE geometry.

The first pic should require a DC shaft, based on any info you'll find on High Angles or Tom Wood's web pages, or billa vista's PBB dissertations. Point the diff at the TC and it's a DC shaft.

The second pic is the proper geometry for a standard drive shaft (meaning no CV joints) as long as the flanges are perfectly parallel ( think a margin of. 1-2 degrees is stated acceptable)

Thing is, especially with a 3-link, I'd think caster would trump driveline angle, unless cutting the knuckle balls off and turning the entire housing. If cutting and turning, guess the options there for either, but the flanges parallel is the same as the rear and shouldn't require a CV jointed DS.

Yep, with the front housing caster trumps "pointing the pinion at the output flange" you can do it in the rear, but the front you would either need to do a cut and turn or a custom housing. I fought it with my 55, the only way I could solve it was run mostly parallel I think I was within 2 or 3 degrees.

- Thread starter

- #85

The first pic should require a DC shaft, based on any info you'll find on High Angles or Tom Wood's web pages, or billa vista's PBB dissertations. Point the diff at the TC and it's a DC shaft.

My driveline angle looked like the first pic for the last couple of years and I never had any vibes with my stock DS. I must have been really lucky. Is the angle of the diff in this first pic showing good caster (3ish degrees)?

VCCruzr said:Is the angle of the diff in this first pic showing good caster (3ish degrees)?

Search "caster". Bahahaha.

I can't say what's depicted, caster wise.

Based on my own drive shaft(s), it wouldn't surprise me that yours may not have, but a lot of variables can account for why it may not have.

For reference.

Source.

http://www.4xshaft.com/driveline101.html

The most cost effective way is to set your caster and go with hubs and forget about the drive line

The most cost effective way is to set your caster and go with hubs and forget about the drive line

X 1 million. They have not addressed the problem or fixed anything. Just swept it under the rug until it appears again further down the track. I'm not having a dig at anybody here. Just saying to save yourself a few years and instead build the housings you need to address the issues.

But people don't like to accept anything knew, and all think their way is the best. Mean while Chris is spending big $$$ actually seeing what WILL work. And I think others should commend him for spending the time/money to show what works.

Search "caster". Bahahaha.

I can't say what's depicted, caster wise.

Based on my own drive shaft(s), it wouldn't surprise me that yours may not have, but a lot of variables can account for why it may not have.

For reference.

Source.

http://www.4xshaft.com/driveline101.html

View attachment 715010

View attachment 715011

Let me just say, that second pic is only barely workable at factory lift. And is way out at a decent lift height. As the first pic, that is the correct set up. No vibs regardless of lift height.

TheBigBoy said:No vibs regardless of lift height.

The biggest issue in some linked suspensions utilizing this method is the driveline binds, negating the effectiveness.

Derrick,

I tried to find, but the app continually crashes, a thread on PBB by " billybob" of Hellfire Fabworks, where he linked an LX.

May be useful info.

The biggest issue in some linked suspensions utilizing this method is the driveline binds, negating the effectiveness.

Derrick,

I tried to find, but the app continually crashes, a thread on PBB by " billybob" of Hellfire Fabworks, where he linked an LX.

May be useful info.

It doesn't bind. I'm maxing 14" shocks and still not binding. It's with in the cv's working angles.

Going part time is only needed if you have a lift height where proper caster yields drive shaft angles that are out of spec for either of the two excepted designs.

The hardest of the two designs to satisfy for is a DC shaft. The front u-joint operating angle must be 0* +/- 1*. So it's a small target window that takes some precision to hit.

When you are around 4" you are where angles intersect and caster meets a zero operating angle at the diff. In this area a stock shaft won't work but a DC will. However since there is such a small target window for the shaft you must now put it's needs first other wise chance having a vibrating drive line.

So if you are at 4" and have a vibrating drive line you likely missed the mark and can easily verify this by measuring the operating angle of the front u-joint.

Higher lifts start to move away from a DC shaft setup back to a stock shaft with a traditional setup.

The problem areas are the operating angles just outside of the what a DC shaft requires but not far enough out for a stack shaft to work.

The hardest of the two designs to satisfy for is a DC shaft. The front u-joint operating angle must be 0* +/- 1*. So it's a small target window that takes some precision to hit.

When you are around 4" you are where angles intersect and caster meets a zero operating angle at the diff. In this area a stock shaft won't work but a DC will. However since there is such a small target window for the shaft you must now put it's needs first other wise chance having a vibrating drive line.

So if you are at 4" and have a vibrating drive line you likely missed the mark and can easily verify this by measuring the operating angle of the front u-joint.

Higher lifts start to move away from a DC shaft setup back to a stock shaft with a traditional setup.

The problem areas are the operating angles just outside of the what a DC shaft requires but not far enough out for a stack shaft to work.

This is exactly what I don't understand. In factory form its pretty close to what you call a "traditional" set up. Bottom uni at 0. Top taking all the angle. Lift it 1" and your already over your 1 degree angle allowance. Caster HAS TO BE RIGHT. So it's simply impossible to have the dc shaft to work. That window doesn't exist. Not without alot of modification. And if your going to modify it. It's way more beneficial to do a parallel flange set up. That way it's always correct.

Ill even put the pics here for you to see.

Ill even put the pics here for you to see.

This is exactly what I don't understand. In factory form its pretty close to what you call a "traditional" set up. Bottom uni at 0. Top taking all the angle. Lift it 1" and your already over your 1 degree angle allowance. Caster HAS TO BE RIGHT. So it's simply impossible to have the dc shaft to work. That window doesn't exist. Not without alot of modification. And if your going to modify it. It's way more beneficial to do a parallel flange set up. That way it's always correct.

Are you taking your reading while the truck is on a lift and the suspension at full droop?

Are you taking your reading while the truck is on a lift and the suspension at full droop?

That would be stupid wouldn't it. Stock 80, stock lift, correct caster. Lets decifer this by the means of elimination. Yes or no answers.

1. Do you agree that - to keep correct caster, the pinion angle (diff centre angle) never changes regardless of lift height?

Cut-n-turn  problem solved

problem solved

Cut-n-turnproblem solved

I've said that a few times. And then it would work dc shaft. But you would be better off with the PF design. That way if you change your lift at any stage, it will always be correct.

Cut-n-turnproblem solved

Cut and turn's even on a FJ40/60 housing require relocating the spring perches. Think of all the brackets that would need to be cut off and welded back on afterwards. Not really a feasible option.

Similar threads

- Replies

- 1

- Views

- 392

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)