I am new to Ih8mud. I have posted a couple of threads looking for a gear for my FJ55 1973 aft glass. I am not sure I am posting them in the right place. I received several suggestions that I have followed to no avail. Shapeways is gone, Spector can't get them, etc. Someone sent me the code for 3D printing, but I can't find the message. ANY HELP WOULD BE REALLY APPRECIATED.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1973 FJ55 Rear Window Gear

- Thread starter Drice

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?May I suggest you broaden your audience by submitting your request to the FJ55 Iron Pig Preservation Society in the forum at the bottom of the forum page. I believe there are a couple of folks down there making that gear.

If they direct messaged you, click on the envelope icon up by your name on the top right

- Thread starter

- #4

Not There. I am really frustrated by my inability to figure out the site and threads.If they direct messaged you, click on the envelope icon up by your name on the top right

- Thread starter

- #5

Thank You. I thought I did, but maybe not..May I suggest you broaden your audience by submitting your request to the FJ55 Iron Pig Preservation Society in the forum at the bottom of the forum page. I believe there are a couple of folks down there making that gear.

FJ55 Iron Pig Preservation Society

Home for the "Knights" to discuss restoration items unique to the FJ55 Series wagons.

forum.ih8mud.com

forum.ih8mud.com

The is a 3d printing thread for files to download - maybe its there. There are places online that will print or machine parts for you. Not a fan of plastic gears, myself.

- Thread starter

- #7

Thank You..I appreciate the start.

FJ55 Iron Pig Preservation Society

Home for the "Knights" to discuss restoration items unique to the FJ55 Series wagons.forum.ih8mud.com

The is a 3d printing thread for files to download - maybe its there. There are places online that will print or machine parts for you. Not a fan of plastic gears, myself.

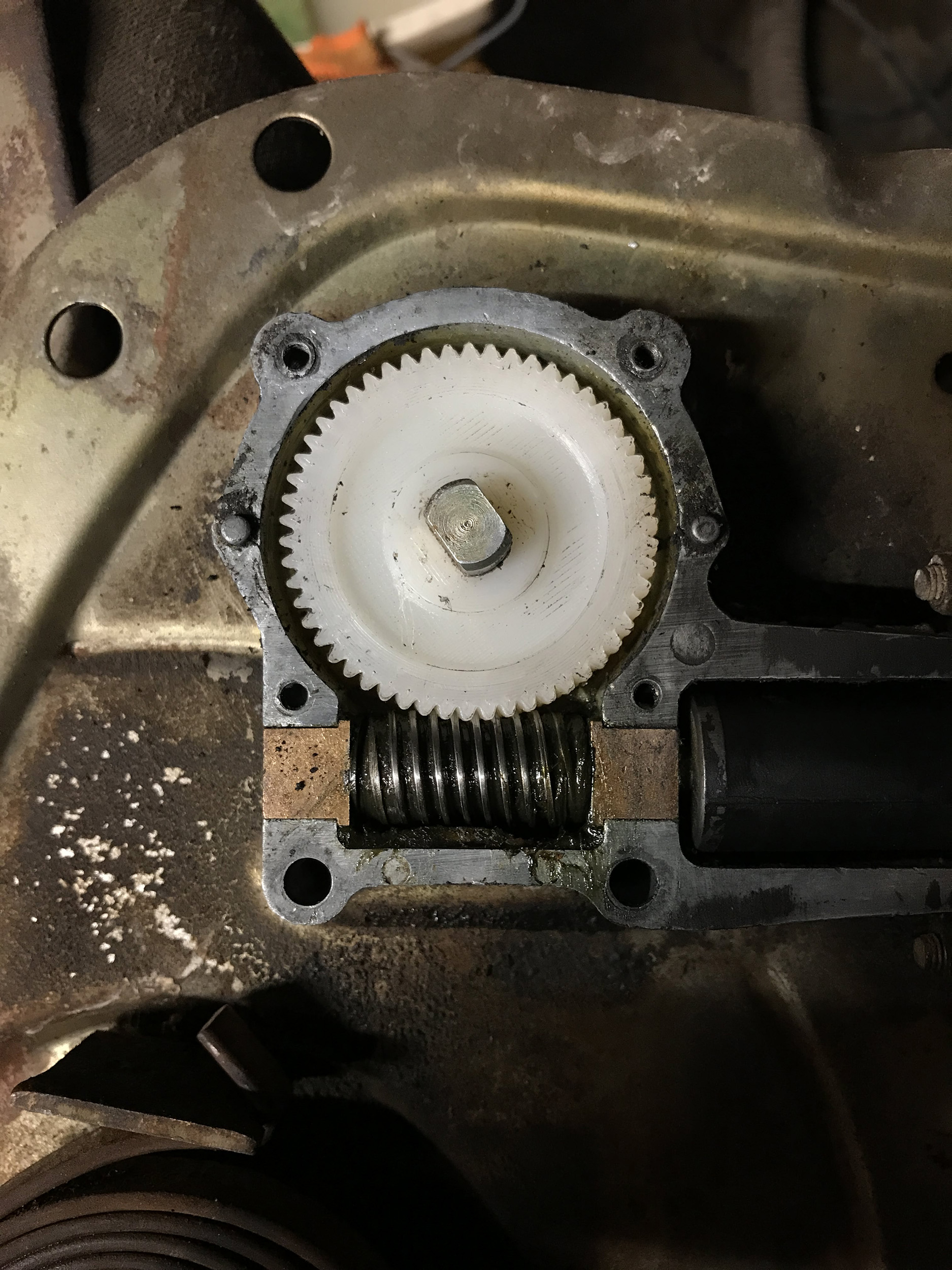

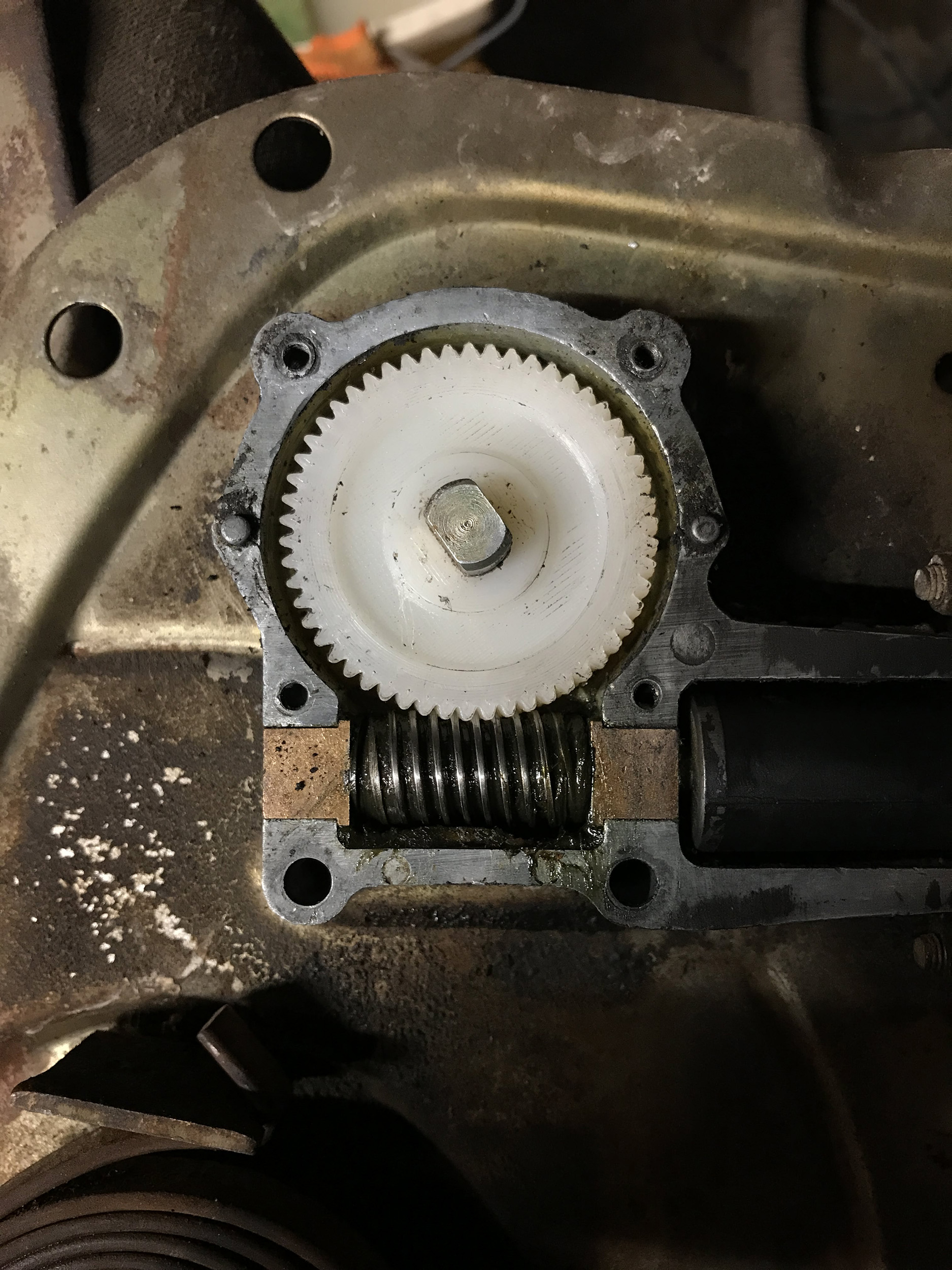

Well, they were plastic from the factory. Replacements were available from the dealer for a long time. I think the plastic gear was supposed to be the "fuse" and break before the worm gear broke.Not a fan of plastic gears, myself.

It was Toyotas first try at a power window...

Green Bean

SILVER Star

By the way...if you find a CAD drawing but don't have the ability to 3D print, I recommend using "Send-Cut-Send" Their prices are reasonable and service is fast.

POTATO LAUNCHER

TLCA #6928

I have had great success with this product. They offer a few things that are NLA for the 55 series.

Shapeways Marketplace Update - Shapeways Blog

We wish the circumstances were different, but unfortunately the marketplace won’t be available in the way it existed before July 2024. We understand this

www.shapeways.com

- Thread starter

- #11

I have tried them. They are either out of business or unresponsive. One person said they were bankrupt.I have had great success with this product. They offer a few things that are NLA for the 55 series.

Shapeways Marketplace Update - Shapeways Blog

We wish the circumstances were different, but unfortunately the marketplace won’t be available in the way it existed before July 2024. We understand thiswww.shapeways.com

POTATO LAUNCHER

TLCA #6928

Haven't used them in a while. Good product when you could get it.I have tried them. They are either out of business or unresponsive. One person said they were bankrupt.

- Thread starter

- #13

Just looked them up. Bankrupt. I am on a total goose chase. I have tried every supplier to no avail. I don't have the information to provide a 3D printer. It has gotten totally crazy.Haven't used them in a while. Good product when you could get it.

Do you have the bad gear? Is it just like a few stripped out teeth? My dad, back in the early 70's repaired the speedometer drive gear for a Rambler. He hot rodded (melted in place) brass welding rod pieces were the stripped teeth were. He hand filed the the brass rod tips to match the tooth profile - worked like a champ.

There is a youtube where the guy using some sort of silicon to cast like a quarter section of a plastic gear where the teeth are good. He filed out the bad area, installed some small screws provide a good bite for the repair. He moves the mold over to where the bad teeth are and pours in some sort of fiber reinforced plastic/epoxy. Super glue and baking soda is fairly tough.

Measuring/drawing the gear isn't all that hard. Fusion 360 is sort of free. There are other cad programs too.

There is a youtube where the guy using some sort of silicon to cast like a quarter section of a plastic gear where the teeth are good. He filed out the bad area, installed some small screws provide a good bite for the repair. He moves the mold over to where the bad teeth are and pours in some sort of fiber reinforced plastic/epoxy. Super glue and baking soda is fairly tough.

Measuring/drawing the gear isn't all that hard. Fusion 360 is sort of free. There are other cad programs too.

- Thread starter

- #15

You know what, this might lead me to the answer. I don't think it can be repaired, but a 3D place can probably replicate. Thanks for re-engaging my brain.Do you have the bad gear? Is it just like a few stripped out teeth? My dad, back in the early 70's repaired the speedometer drive gear for a Rambler. He hot rodded (melted in place) brass welding rod pieces were the stripped teeth were. He hand filed the the brass rod tips to match the tooth profile - worked like a champ.

There is a youtube where the guy using some sort of silicon to cast like a quarter section of a plastic gear where the teeth are good. He filed out the bad area, installed some small screws provide a good bite for the repair. He moves the mold over to where the bad teeth are and pours in some sort of fiber reinforced plastic/epoxy. Super glue and baking soda is fairly tough.

Measuring/drawing the gear isn't all that hard. Fusion 360 is sort of free. There are other cad programs too.

Well if you go to all the work to make one, then do several, to help out others. Unit cost isn't much compared to the time to draw it up and proof the code. What the plastic gears was like $20, I doubt there was more than fiddy cents worth of plastic involved. Besides you will want a spare or two.

You could also 3d print a little larger (5%), then cast it in brass using the lost PLA technique.

You could also 3d print a little larger (5%), then cast it in brass using the lost PLA technique.

WarDamnEagle

SILVER Star

I'm pretty sure someone on here uploaded the file to Shapeways so it should be available - maybe.

MOTOV8R

SILVER Star

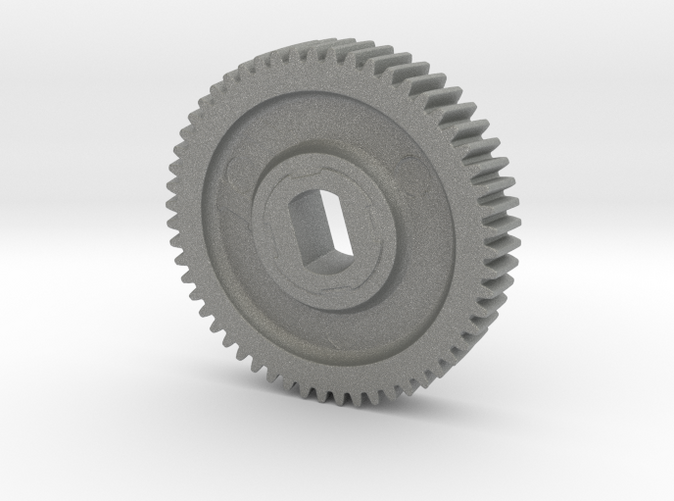

fj55 rear window gear by fj55_100 on Shapeways

Check out fj55 rear window gear by fj55_100 on Shapeways and discover more 3D printed products in Mechanical Parts.

MOTOV8R

SILVER Star

Can also download the stl here:

Fj55 Rear Power Window Driven Gear - Classic Expedition Vehicles

Part Files: Fj55 Fj55 Rear Power Window Driven Gear Download STL Material PCTPE or Nylon (I used Taulman PCTPE) Infill Density 100% Infill at 0.05mm layer height and .25nozzle Infill Pattern Rectilinear Perimeters I used 10 perimeters to add some extra structure around the hub. Notes Check...

classicexpeditionvehicles.com

MOTOV8R

SILVER Star

@ChaserFJ60 does printing. If you get the file or direct him to it he can probably get you one made.

Similar threads

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)