Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

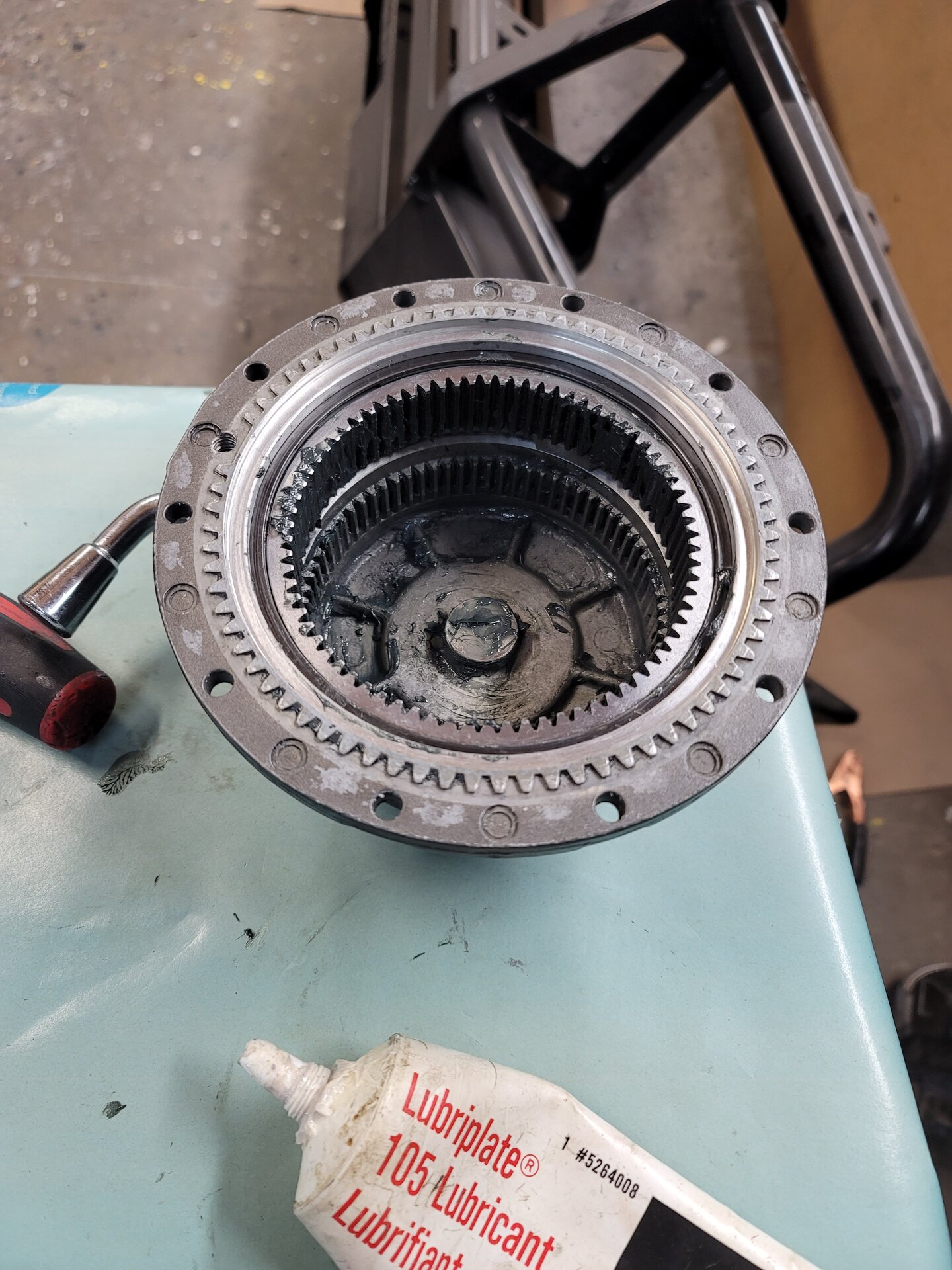

Warn M15000 Rebuild. (2 Viewers)

- Thread starter JDMGoodness

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?- Thread starter

- #62

With the smoothed burrs and the removal of the grease it works as it should.

I had to adjust the 2 circlips that lock in the free spool gear. They were slightly tweaked but a little reshaping and they fit right in.

Now I know not to grease the free spool.

Bench tested the winch with a battery pack. Works and sounds like it should.

Can anyone confirm the wong/theory of the brake/free spool?

When in free spool it can be hand spun forward and back. It can also be powered in and out and if you hold the drum it will not spin the drum. That is how it should work in free spool.

My question is when it locked. What holds the weight when locked and powering in and out? I don't think the brake itself holds the weight?

All my observations are bench testing with no line or weight on the winch.

With the winch in locked position it powers in and out no problem. Once I let off it will not rotate any further than the detents in the free wheel gear. The free spool lever stops it from moving any further forward or back. Rotating it by hand not under load you can hear it hit the stop forward and back.

What 'holds' the weight of the vehicle when winching up a hill? If I power the winch and stop I can't turn the winch any further by hand as if the brake is holding it. If I rotate it the other way it frees itself a bit until it rotates and hits the free spool lever detent which I can rotate like previous under no load. It seems iediately after witching it is being stopped and held. Is it the brake assembly or the free spool lever detent not allowing to physically move because it's resting against it.

I'm pretty sure I have everything together the right way. Without it mounted or under real load it's hard to duplicate a real world load on it.

I had to adjust the 2 circlips that lock in the free spool gear. They were slightly tweaked but a little reshaping and they fit right in.

Now I know not to grease the free spool.

Bench tested the winch with a battery pack. Works and sounds like it should.

Can anyone confirm the wong/theory of the brake/free spool?

When in free spool it can be hand spun forward and back. It can also be powered in and out and if you hold the drum it will not spin the drum. That is how it should work in free spool.

My question is when it locked. What holds the weight when locked and powering in and out? I don't think the brake itself holds the weight?

All my observations are bench testing with no line or weight on the winch.

With the winch in locked position it powers in and out no problem. Once I let off it will not rotate any further than the detents in the free wheel gear. The free spool lever stops it from moving any further forward or back. Rotating it by hand not under load you can hear it hit the stop forward and back.

What 'holds' the weight of the vehicle when winching up a hill? If I power the winch and stop I can't turn the winch any further by hand as if the brake is holding it. If I rotate it the other way it frees itself a bit until it rotates and hits the free spool lever detent which I can rotate like previous under no load. It seems iediately after witching it is being stopped and held. Is it the brake assembly or the free spool lever detent not allowing to physically move because it's resting against it.

I'm pretty sure I have everything together the right way. Without it mounted or under real load it's hard to duplicate a real world load on it.

Last edited:

When in free spool it can be hand spun forward and back. It can also be powered in and out and if you hold the drum it will not spin the drum. That is how it should work in free spool.

CORRECT

My question is when it locked. What holds the weight when locked and powering in and out? I don't think the brake itself holds the weight?

THE BRAKE HOLDS THE WEIGHT OF THE LOAD.

CORRECT

My question is when it locked. What holds the weight when locked and powering in and out? I don't think the brake itself holds the weight?

THE BRAKE HOLDS THE WEIGHT OF THE LOAD.

Most winches of that vintage used a brake that has some form of cam or ramp action from the geartrain where if you apply pulling force to the cable on the drum the brake force increases when the motor is not running.

The brake works only in one direction and yes, it holds all the load through the gear reduction.

The earliest design Bellview's had an external band brake. Then the 8274 used the external ratchet pawl brake. The newest design consumer grade winches use more complex mechanisms that interact with the freespool lever so you can just hit the button instead of having to walk back and engage the lever. Industrial winches use electric or hydraulic releasing brakes.

The consumer winches have the most problems with the brake. That's what's going to fail if you push it too far. The planetary gears will hold. It will be parts of the brake or that hex driveshaft if it's part of the brake at all.

The brake works only in one direction and yes, it holds all the load through the gear reduction.

The earliest design Bellview's had an external band brake. Then the 8274 used the external ratchet pawl brake. The newest design consumer grade winches use more complex mechanisms that interact with the freespool lever so you can just hit the button instead of having to walk back and engage the lever. Industrial winches use electric or hydraulic releasing brakes.

The consumer winches have the most problems with the brake. That's what's going to fail if you push it too far. The planetary gears will hold. It will be parts of the brake or that hex driveshaft if it's part of the brake at all.

- Thread starter

- #65

When I spool it as it sits on the bench with a battery pack it rotates the drum. As soon as it stops I can't move it by hand. When I rotate the drum a little the other way I can then spin the drum back and forth until it hits the detents of the free spool ring.

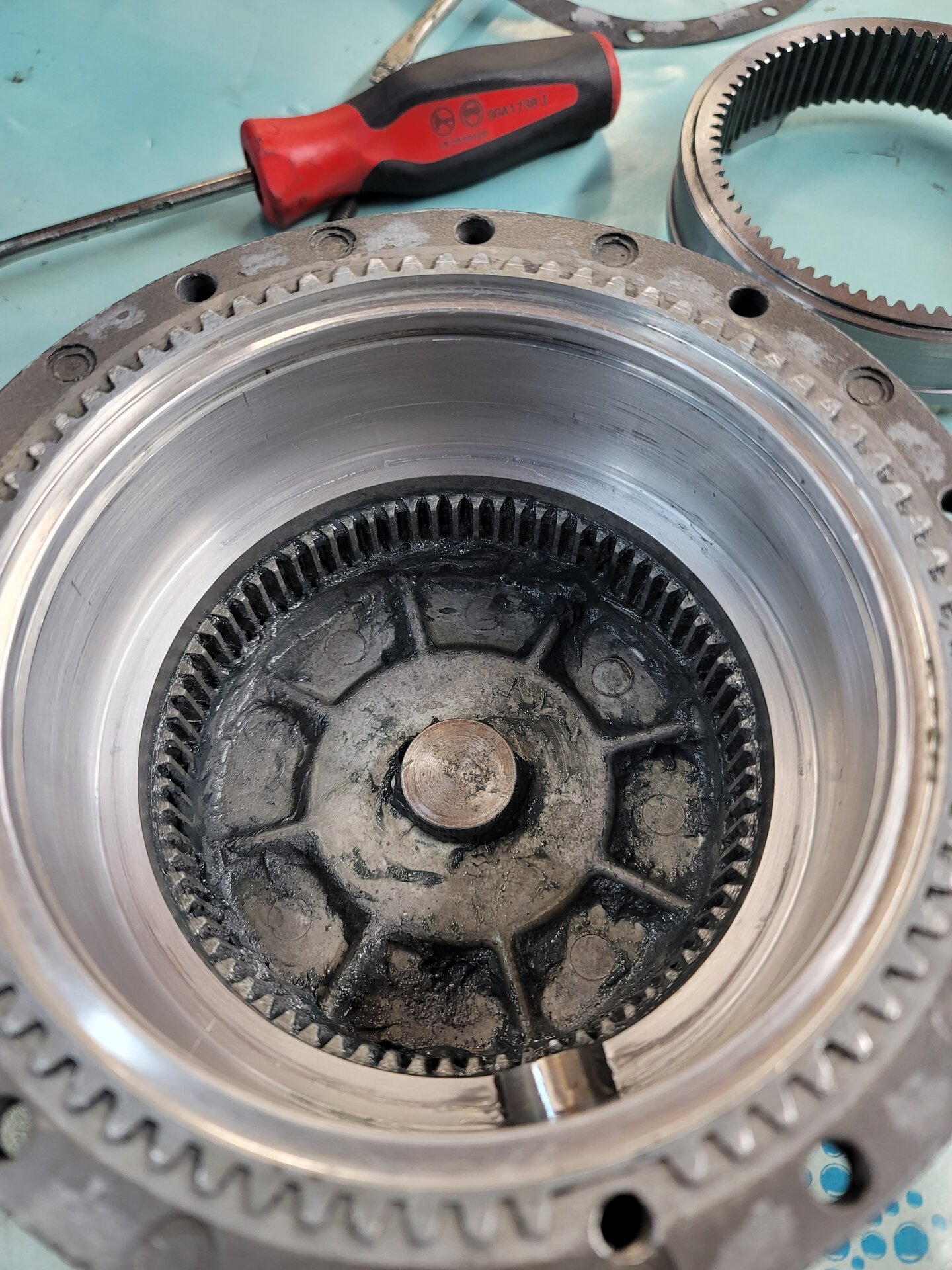

When that ring hits the lever. Pics for clarity.

When that ring hits the lever. Pics for clarity.

Not sure what problem you are describing. Trouble getting out of freespool?

- Thread starter

- #67

Hopefully no problem. Freespool engages and disengaged with the lever. That's

working.

Trying to confirm what holds the winch under load when you can't put it under load when bench testing only.

working.

Trying to confirm what holds the winch under load when you can't put it under load when bench testing only.

Hopefully no problem. Freespool engages and disengaged with the lever. That's

working.

Trying to confirm what holds the winch under load when you can't put it under load when bench testing only.

You're trying to confirm if the brake is working properly?

The way we did it at the OEM level was to mount a winch on a test frame, essentially a pair of 14" I-beams about 10' long with a plate and modular bracketry on top, hook the winch cable to a hydraulic cylinder and apply an appropriate amount of hydraulic pressure pulling on the cable.

For testing, you need to have the winch mounted solidly to a frame. These little winches are not designed to self support, they need a solid substrate to hold them together.

Hope this helps.

The brake holds the load. To test the brake I install the winch in something, run a snatch block over a stout tree limb and pick up a log or something (front end of your vehicle or another vehicle if you are brave.

FYI, for lifting/hoisting, a vehicle winch is designed for minimum 25% of it's rated capacity. So if you have a 15K winch it should lift and the brake should hold 3750 lbs. Over that and it'll work until it doesn't lol.

That’s actually great info. Gives me an idea of what the test load should be for my 8274 rebuilds.FYI, for lifting/hoisting, a vehicle winch is designed for minimum 25% of it's rated capacity. So if you have a 15K winch it should lift and the brake should hold 3750 lbs. Over that and it'll work until it doesn't lol.

sleepycruiser

I will get by….I will survive -Touch of Grey LC200

Can this winch run off the vehicle battery or would I need to add an additional battery?

Similar threads

Users who are viewing this thread

Total: 3 (members: 0, guests: 3)