- Thread starter

- #61

Spent a bit of time in the garage today. Nothing to exciting though. Removed some misc bolts out of the tub. Got the dash pretty well disassembled. Sadly some of the screw heads broke off while removing the dash pad so will have to get those out.

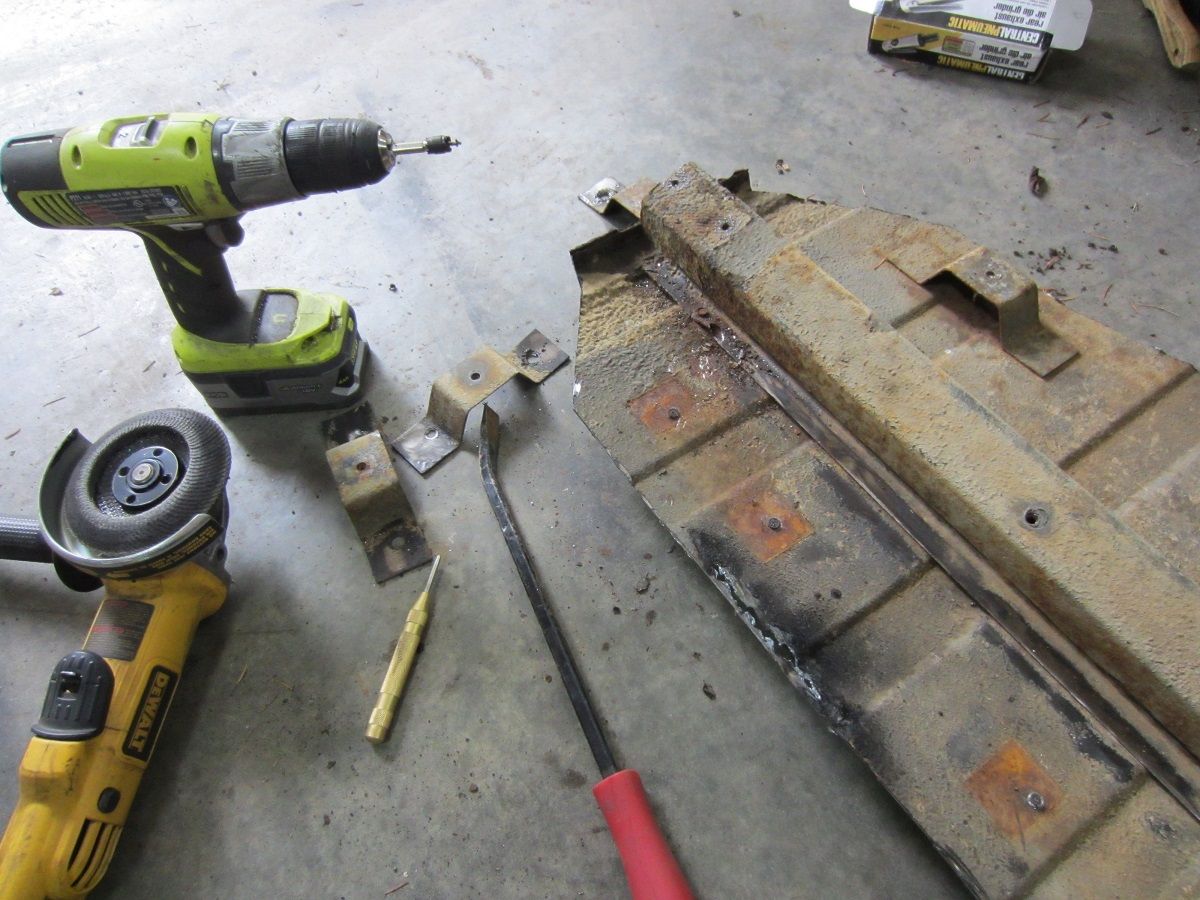

I did take advantage of the break in the rain to cut the brackets off the old tub. Got the "skid plate" off to find them in pretty dang good condition really.

So i cut out the section and took it into the garage to work on it. Of course the rain didnt come back so i could have just done this on the old tub. But the old tub is scrap anyways.

I tried out the harbor freight spot weld cutter and have to say it works pretty well. Hardest part is finding the spot weld. The brackets were easy but the channel piece doesnt seem to be as easy.

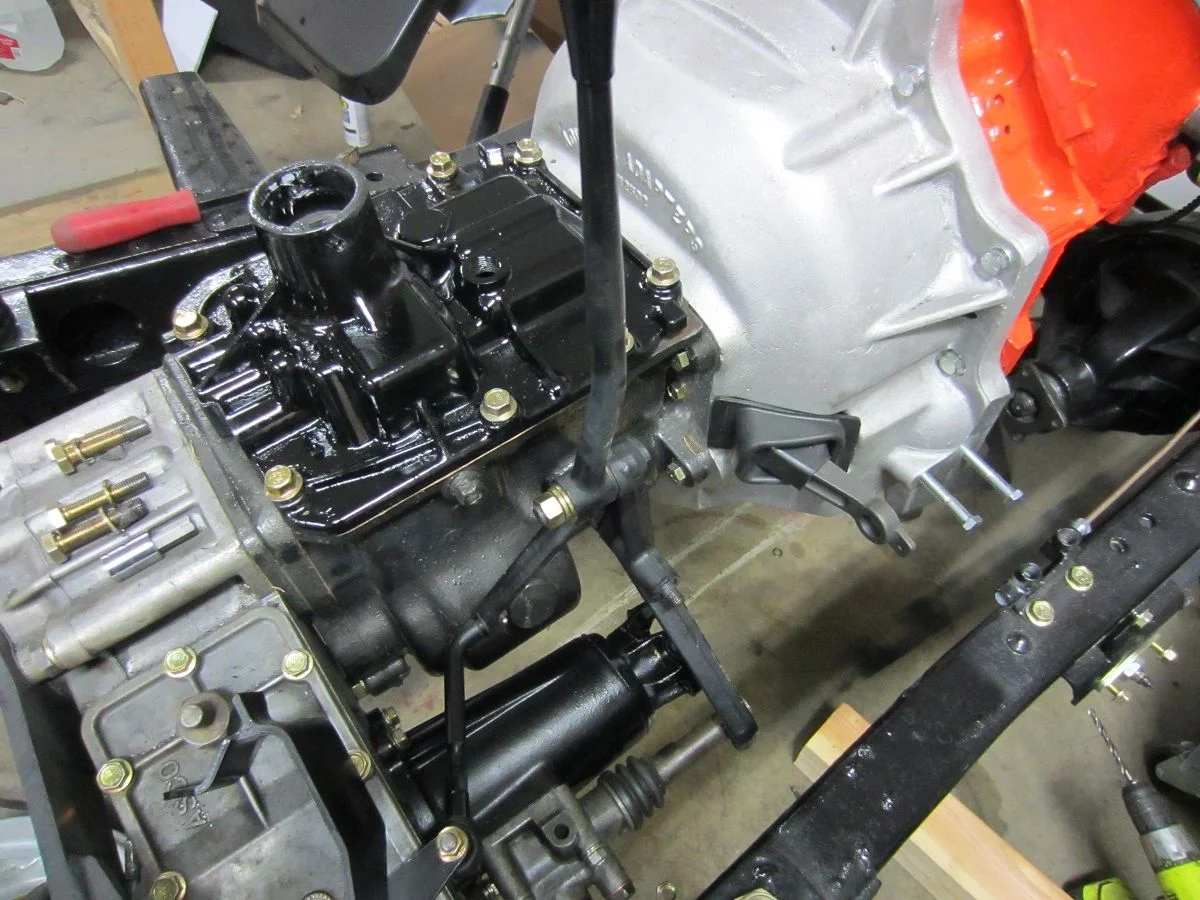

I also tackled a few little things too. Got the transfer case fill plug removed finally (needed the air hammer). So filled it up and attached the bypass hose finally. Also got the rear pinon nut torqued. So filled the rear axle with gear oil. Then checked the front and topped it off. Id filled it when not on the vehicle so it was a cup or two low.

I did take advantage of the break in the rain to cut the brackets off the old tub. Got the "skid plate" off to find them in pretty dang good condition really.

So i cut out the section and took it into the garage to work on it. Of course the rain didnt come back so i could have just done this on the old tub. But the old tub is scrap anyways.

I tried out the harbor freight spot weld cutter and have to say it works pretty well. Hardest part is finding the spot weld. The brackets were easy but the channel piece doesnt seem to be as easy.

I also tackled a few little things too. Got the transfer case fill plug removed finally (needed the air hammer). So filled it up and attached the bypass hose finally. Also got the rear pinon nut torqued. So filled the rear axle with gear oil. Then checked the front and topped it off. Id filled it when not on the vehicle so it was a cup or two low.