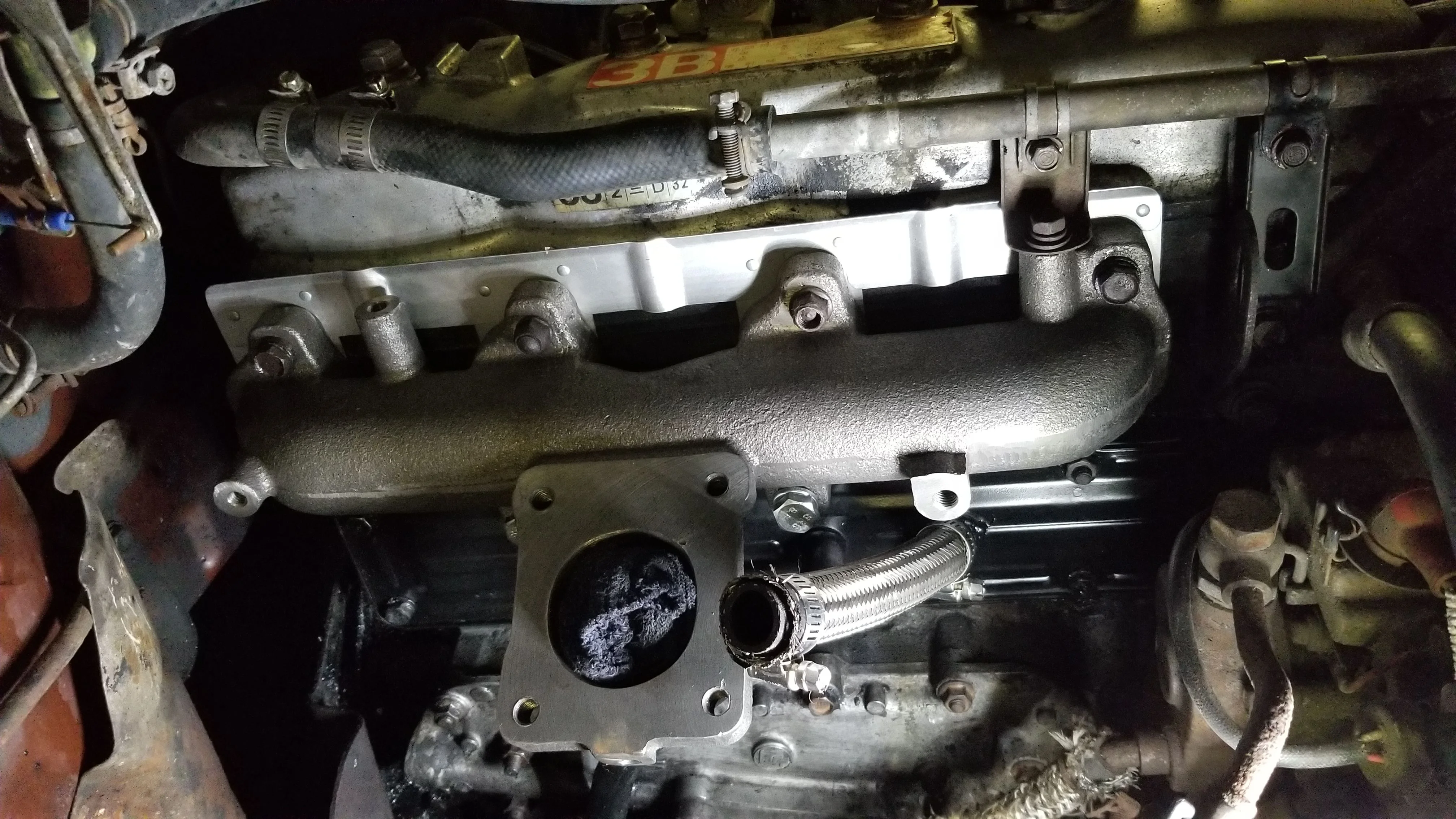

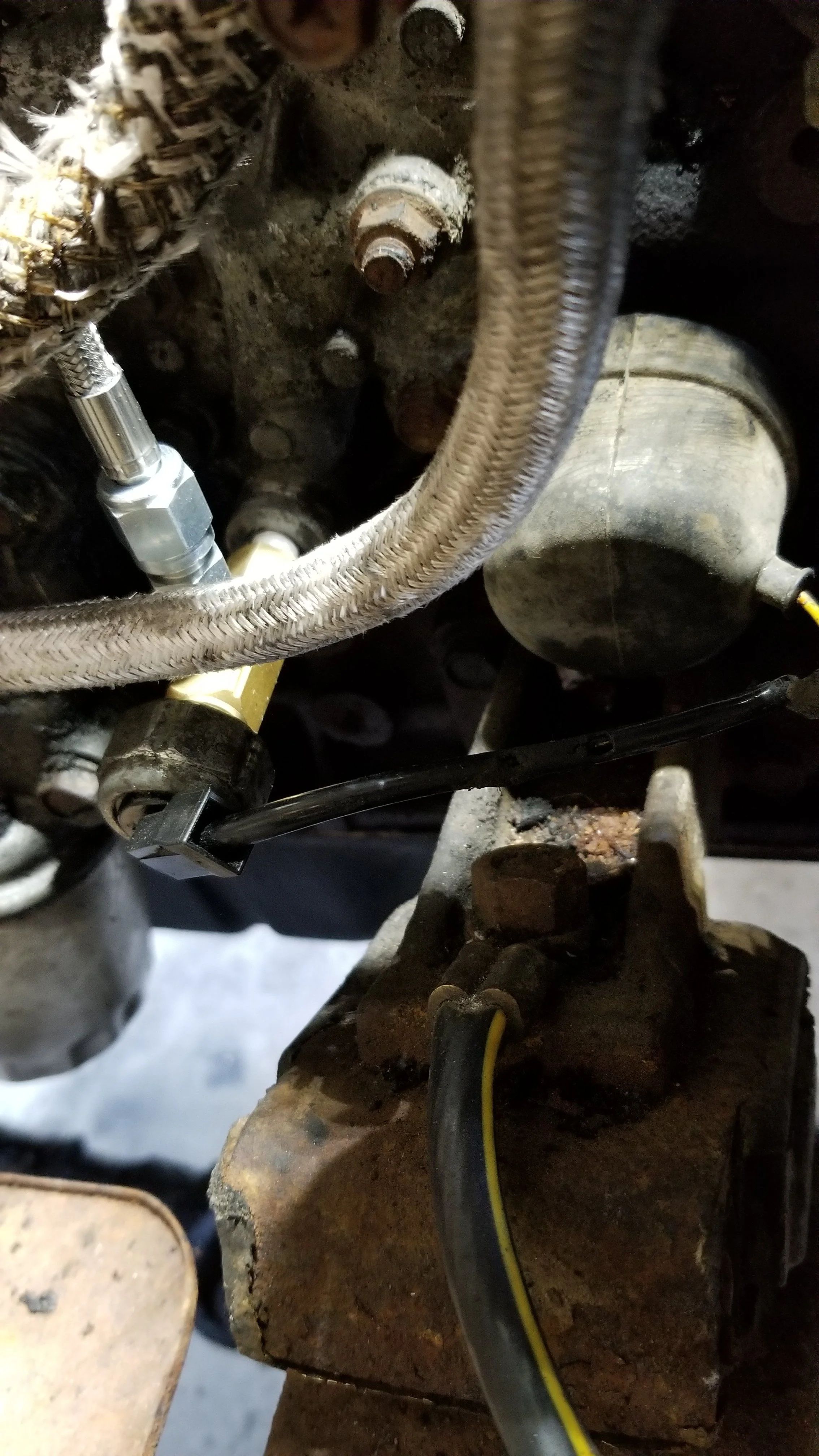

I have the upfacing oilfilter and I used a 13bt manifold for my turbo, I use a wix 51085 like Greg mentioned with no problems Its basically half the size of the original. It fits in there just fine though and been doing that for 8 years.

Looks like a great product from a great guy. I wouldnt hesitate to buy one!

Looks like a great product from a great guy. I wouldnt hesitate to buy one!

Last edited: