tucker74

Moderator

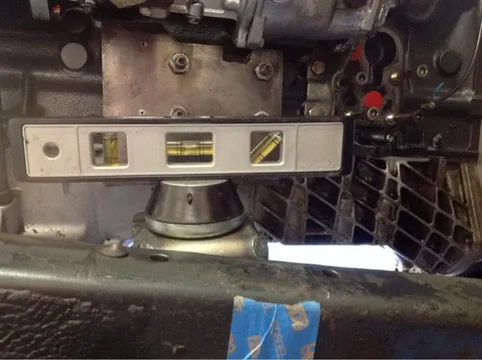

Should be fine with 1", really depends how soft of mounts you go with. You want some dampening so you don't rattle to deathIt's an Advance Adapters 712577 NV4500 bellhousing. Do you think 1" is enough clearance? I may go with a little more since I don't want the fan to eat the radiator.

Looking good!

Tucker