WarDamnEagle

SILVER Star

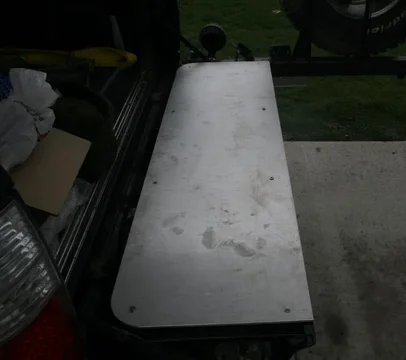

The holes are 8mm.

I'm going to call Great Western on Monday to see if they have shipped yet. If not I'm going to check on having them round the top edge. A carbide router bit cost over $20 and I am guessing they can do it for less than that.

If they had the blueprint on file I would have them drill and counter sink the holes as well. I considered shipping them my carpet but have to agree with Cdan - there is too much slop using the carpet as a blueprint for an accurate product. I say this because even with all 16 of the plastic connectors in, the carpet still slides around slightly. If you have ever had the carpet off you will know what I am talking about. The plastic connectors slide into an over sized hole and float around a bit.

Now if they had an actual tailgate to work from I think they could make it work.

Thanks. I would mail you my bit but it's at my MIL's and I don't think she could find it. 1/16" radius is not easy to find!

This might help. I don't know the hole size.

-B-

Thanks Beowulf. That does help. I've never taken my carpet off so I had no idea what the bare tailgate looked like.