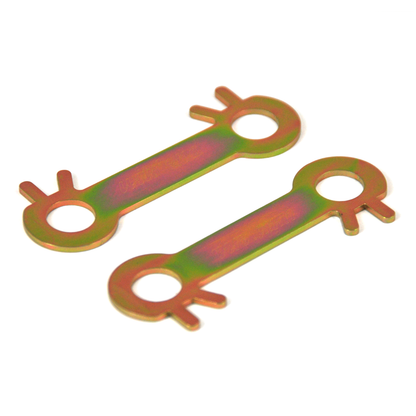

I have been wheeling on 35's for 8 years and just last week i installed 37" tires and drove up coyote ridge. Its not a difficult trail, however i manages to break off my steering knuckle studs and left my truck stranded. I had to drive 2.5 hours with my friend truck into Bishop and pickup up some bolts at Napa and drove back out to my truck. I was able to recover some of the cone washers on the trail and was able to secure the steering arm back on the knuckle and drive 6 hours home without issue. I was suffering from altitude sickness and was feeling miserable so i wasn't thinking about taking pictures of the carnage. I find the breakage timing questionable since I have been wheeling harder and more technical trails for over 8 years on 35"s without failure.

Questions;

Are 37" the breaking point of the stock steering and without upgrade failure to inevitable?

Was the breakage directly a result of failure to recheck the torque on the steering studs?

As long and the steering studs are constantly re-torqued with stronger upgraded studs is it safe to run 37"s on hard trails.

I know the best answer is Hellfire, Slee arms, for Front range, however that is not an option at this time, but definitely in the future.

Im just considering to going back to 35's (315's) if steering breakage is common with 37's

Input appreciated...

Questions;

Are 37" the breaking point of the stock steering and without upgrade failure to inevitable?

Was the breakage directly a result of failure to recheck the torque on the steering studs?

As long and the steering studs are constantly re-torqued with stronger upgraded studs is it safe to run 37"s on hard trails.

I know the best answer is Hellfire, Slee arms, for Front range, however that is not an option at this time, but definitely in the future.

Im just considering to going back to 35's (315's) if steering breakage is common with 37's

Input appreciated...