What's that tranny? In layman's terms, not the number. What's it out of? What are it's capacitys? It looks like it is out of a tank. Or a Kennworth.

I like the progress.

Thanks!

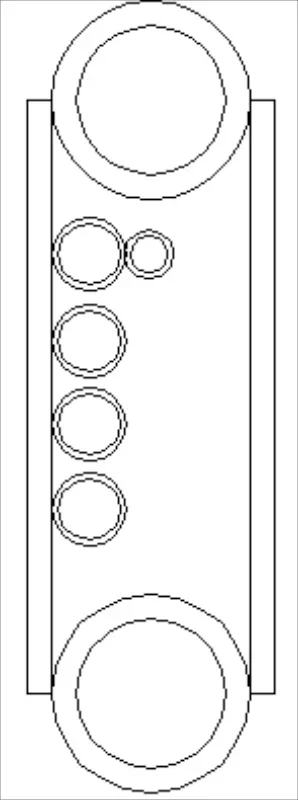

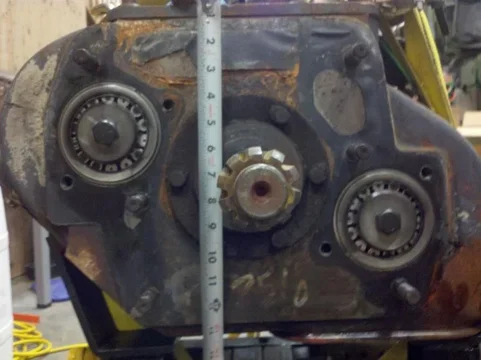

The transmission is an Eaton Fuller. It is part of Eaton's truck drivetrain component line they call Roadranger. That includes axles, clutches, etc. These transmissions come in a wide range of styles. Hundreds. Mine is a RTO-14709mll. To break that down: rto stands for Roadranger Twin countershaft Overdrive. The 14 is the nominal torque input rating, in hundreds of foot-pounds (actually 1450 for this model). The 7 is the design level (6 had straight cut auxiliary gears [loud!], 7 had helical cut ones, and 9 has an improved rear output seal design.) The last two digits are the number of forward road gears. 9 in my case. The next letter is the ratio identifier (in my case, the M is a lower deep reduction reverse gear than the A gearset that was also available). The last two letters indicate that there are two deep reduction gears below the 9 road ratios, meaning this transmission is actually an 11 speed. The two deep reduction gears are not meant for progressive shifting, only for speed control. Whew!

This particular transmission was used extensively in cement mixers and dump trucks, so they could go slow enough to keep pace with paving machines and not burn clutches. Usually those trucks have GVW's around 60,000 pounds. Often they had the Cummins ISC (8.3L) or ISL (8.9L) as a powerplant, too... It is not a very common model, so I looked for a while to find one that I could get for a good deal. They are spendy otherwise.

The RTO line of transmissions are known for being extremely tough, long lasting, and easy to shift (even though there are no synchronizers in the front half of the transmission). It's not unheard of for these to go 500,000-750,000 miles between overhauls, and millions before they are scrapped. And those are hard miles. Mine has 130,000 on it and internally looks new from what I can see.

I will post a link to all of Eaton's literature on the beast as soon as I get to a computer since the app on my phone is not cooperating. The service manual is an excellent read, I think. Lots of pictures, and has all the power flow diagrams for each gear ratio to help visualize how it works.