That looks pretty damn good man.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

I have the same issues to tend too. This has inspired me to start a daily driver face lift thread.

I would like to address the many body issues I have but it is my daily driver. Now that I am in between jobs and states, I think I can pull it off! I have about 2 weeks to do it..... Off to store for bondo, paint, pads, grinding wheel......ect! I'll start the thread soon.

Thanks for the inspiration.

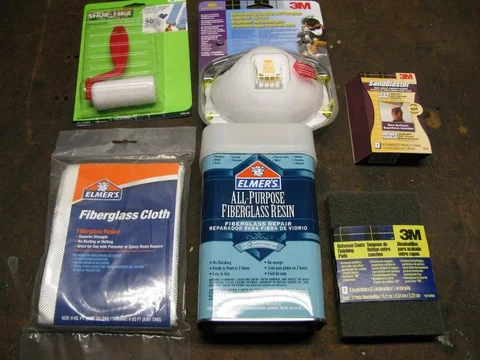

Don't forget the disposable gloves, dust masks and glasses/face shield. Working with the fiberglass can be quite a mess. Might be good to get a bit of extra hardener for the resin too, I found I ran out of hardener before I was through the can of resin.

)

)

I've been doing the same thing to patch up the rust holes in the Bantha's rear fenders. I only get a bit of time to work on it on the weekends, provided that the weather cooperates, so it's taken me almost two months at this point. But every new layer of mat makes it all look and feel more solid, and when I've ground the high spots out and put some cloth on, it actually looks pretty good. Tomorrow's supposed to be rainy, so I probably won't finish up this weekend, but I'm really hoping to be able to post up some pictures of the finished work soon. Unfortunately, I didn't take any "before" or "in progress" pictures to compare against, but they're basically like the ones that have been posted here. At any rate, it's good to see at least two other Mudders going the same route. I guess we'll have to compare notes in a year or two to see how these patches hold up.

Anyhow, a couple of hints that I've found:

- Get yourself a 100 count box of nitrile gloves. Each pair will only last for a single 15-minute application.

- Get a 15-pack of 2" chip brushes from Home Depot. You'll use one for each application.

- Get an extra bottle of hardener. The ones that come with the resin won't last for the entire can.

- Mat builds up faster and feels stronger when cured, but is way harder to work with than fabric. Depending on your application, it might be better to go with more layers of fabric than fewer layers of mat.

- Use just the tip of the brush when pressing out bubbles/smoothing the mat (or fabric). Especially with the mat, the sides of the brush will grab the fibers and make a total mess of your work.

- You might find it easier to mix the resin a little hot, and work in smaller batches, than risk a batch that doesn't cure, wasting time, resin, brushes, gloves, and mat in the process. (Ask me how I know.)

Given your success, I am tempted to do my rear quarters in fiberflass. Has anyone tried to span a gap of about 4" with fiberglass or would I have to build some sort of structure to support it?

4" span should be fine - use several layers of cloth maybe.

But please take care of the underside rust before you go slathering on fiberglass. That rust will come back - treat it before you glass.

Oh believe me, I will. Just throwing ideas out there because it's a pain in the nuts to weld sheetmetal, especially upside down. My rig will be getting a diet session with the plasma cutter in a week or so I hope.

Welding upside down isn't fun but I would rather weld than deal with resin and cloth.

16 ga sheet is fun to work with!