They just pull the rebar as they go.

it's a poor way to do it and it isn't per the ACI code, but it is done quite often...

as far as your idea of using some constuction adhesive between the aluminum and concrete, that would be a great use!

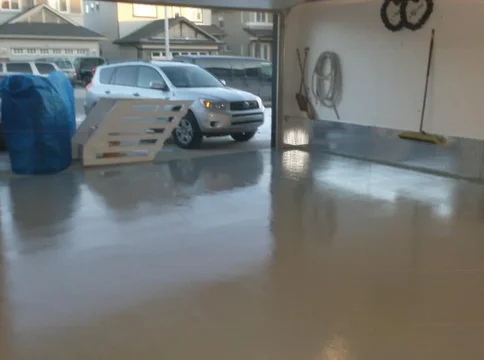

lookin good!

bk