- Thread starter

- #101

next

So here we are with the bend complete, one thing I forgot to mention is you really have to think in 3 dimension and backwards as well because if you lay the template down the wrong way, you end up cutting the groove on the wrong side.

Sorry not to show the welded up back side, I blew threw in one area and had to carefully, fix it filling it in. Looks OK.

next, as mentioned I figured out how to hold it in place, duh... using a strap, worked like a charm. I did have to place a clamp at the bottom as it tended to drop a bit when I ratcheted down on it

next, welded up. I will cut off about 3/4" on bottom and about 1-2 inches in to match it up real nice.

Question to all, what should I do about the top of the side, leave it or add a small piece at a 90 degree angle to the side plate. Problem is , I wanted to leave some room for any body flex.

the plan is to put my mud flaps back on if every thing works out.... cannot have any unnecessary stone chips in my nice new shiny bumper

next steps. finish fabing other pieces, weld on, remove bumper, strip, etch and paint. I should be done in time for Durhamtown....

So here we are with the bend complete, one thing I forgot to mention is you really have to think in 3 dimension and backwards as well because if you lay the template down the wrong way, you end up cutting the groove on the wrong side.

Sorry not to show the welded up back side, I blew threw in one area and had to carefully, fix it filling it in. Looks OK.

next, as mentioned I figured out how to hold it in place, duh... using a strap, worked like a charm. I did have to place a clamp at the bottom as it tended to drop a bit when I ratcheted down on it

next, welded up. I will cut off about 3/4" on bottom and about 1-2 inches in to match it up real nice.

Question to all, what should I do about the top of the side, leave it or add a small piece at a 90 degree angle to the side plate. Problem is , I wanted to leave some room for any body flex.

the plan is to put my mud flaps back on if every thing works out.... cannot have any unnecessary stone chips in my nice new shiny bumper

next steps. finish fabing other pieces, weld on, remove bumper, strip, etch and paint. I should be done in time for Durhamtown....

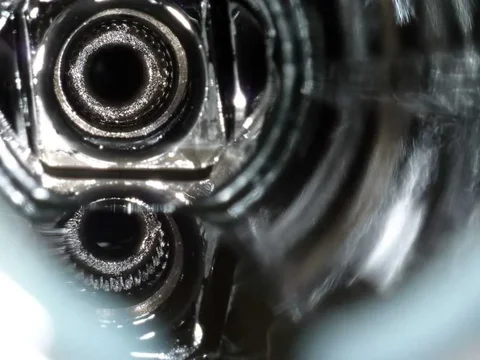

. I will be sleeving it and welding to sleeve and then weld the sleeve to the bumper.

. I will be sleeving it and welding to sleeve and then weld the sleeve to the bumper.

.

.