I am interested too, can you post up some shots?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need your input - would you buy a rear storage drawer "kit"

- Thread starter cruzerDave

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?Following, because I was about to look into doing this exact same thing

I'm rebuilding a set that I did 4 years ago, improving on some things and making changes. Honestly I think you are gonna have a hard time at $750 just breaking even...Maybe on a basic 2 drawer side by side system without locking slides? Just my 2c

Curious to see what you come up with. Good luck!

I'm rebuilding a set that I did 4 years ago, improving on some things and making changes. Honestly I think you are gonna have a hard time at $750 just breaking even...Maybe on a basic 2 drawer side by side system without locking slides? Just my 2c

Curious to see what you come up with. Good luck!

cruzerDave

Land Shark Outfitters

- Thread starter

- #43

To everyone that has responded, thank you. There is some good feedback in the thread, and the comments and votes as of 6/27 (50% <$750, 47% <$600, and only 3% <$500) indicate a low cost, basic kit that can be the basis for customizing is worth spending my time to put together and sell. If everyone had been insistent on sub 500, well, as anyone who has built one or read the threads will know, that is extraordinarily difficult or impossible for strength, quality, and a few bucks profit to bother.

To all asking for photos and specs - I totally get it, but please recall this was an early 'test-the-waters' sort of question. I would not want to post pics of my current system because it is me prototyping - extra holes where things moved, gap where something changed design, etc. That said it has been out twice now and scored by the whole family a 10/10 for quiet and usefulness

Based on what I have heard I think I might be able to sell 10-20 of these over the next 2-3 months, so enough interest to justify me burning dollars on tweaking and making more user-friendly.

I plan to offer the unit at cost to up to 3 good quality beta testers, based on who expresses interest in this thread and what rig they drive (I need an LX) as well as plans to use the drawers in the field in the near future. This will be via PM soon.

As for timing, I have a good sliding mechanism now that works great and I have never seen before, but is $$ and I feel obligated to test bearings and slides first to compare - those are the standbys everyone is used to - parts on the way and that'll take a couple weeks. I'll then get a couple kits to beta testers for feedback. THEN I'll post detailed pics, specifications, testing results, installation instructions (so folks can feel comfortable with what is required before they buy), transparent pricing, and open it up for orders.

In general I can tell you the system is built of 15mm, 12mm, and 10mm true 7-layer baltic birch plywood, and extruded aluminum. Many pieces will be cut on a CNC waterjet for accuracy of assembly and minimization of my time. The unit's design is simple and basic - if someone wants cubby pocket slots in the back they can certainly cut and modify before they install based on this solid, basic platform, but I'm not including in order to keep cost, construction, and assembly down for those that do not want them.

The initial units will be unfinished because finishing reduces potential for individual customization just too much, and if I learned one thing looking at a hundred drawer posts and videos it is that 100 people really have 100 specific wants and needs. I *may* consider a finished system based on a group purchase of the same finish type, but suspect no 10 people will be able to agree on what that finish would be

After I build a batch of the whole drawers and refine my shipping, ordering, and supply chain logistics I *may* propose a group buy for half drawers, to be based on the full set, and only built if I hit enough demand.

Finally, and likely of most interest, I continue to track a likely sale price in the $550-$650 range, with production in lots of 10 taking 2-3 weeks each. But I'm not asking you to believe me yet, just stay tuned

To all asking for photos and specs - I totally get it, but please recall this was an early 'test-the-waters' sort of question. I would not want to post pics of my current system because it is me prototyping - extra holes where things moved, gap where something changed design, etc. That said it has been out twice now and scored by the whole family a 10/10 for quiet and usefulness

Based on what I have heard I think I might be able to sell 10-20 of these over the next 2-3 months, so enough interest to justify me burning dollars on tweaking and making more user-friendly.

I plan to offer the unit at cost to up to 3 good quality beta testers, based on who expresses interest in this thread and what rig they drive (I need an LX) as well as plans to use the drawers in the field in the near future. This will be via PM soon.

As for timing, I have a good sliding mechanism now that works great and I have never seen before, but is $$ and I feel obligated to test bearings and slides first to compare - those are the standbys everyone is used to - parts on the way and that'll take a couple weeks. I'll then get a couple kits to beta testers for feedback. THEN I'll post detailed pics, specifications, testing results, installation instructions (so folks can feel comfortable with what is required before they buy), transparent pricing, and open it up for orders.

In general I can tell you the system is built of 15mm, 12mm, and 10mm true 7-layer baltic birch plywood, and extruded aluminum. Many pieces will be cut on a CNC waterjet for accuracy of assembly and minimization of my time. The unit's design is simple and basic - if someone wants cubby pocket slots in the back they can certainly cut and modify before they install based on this solid, basic platform, but I'm not including in order to keep cost, construction, and assembly down for those that do not want them.

The initial units will be unfinished because finishing reduces potential for individual customization just too much, and if I learned one thing looking at a hundred drawer posts and videos it is that 100 people really have 100 specific wants and needs. I *may* consider a finished system based on a group purchase of the same finish type, but suspect no 10 people will be able to agree on what that finish would be

After I build a batch of the whole drawers and refine my shipping, ordering, and supply chain logistics I *may* propose a group buy for half drawers, to be based on the full set, and only built if I hit enough demand.

Finally, and likely of most interest, I continue to track a likely sale price in the $550-$650 range, with production in lots of 10 taking 2-3 weeks each. But I'm not asking you to believe me yet, just stay tuned

I have a 2004 LX and I am interested in either beta testing or full purchase once the kinks are worked out.

I've been thinking on a design for about six months now and I'd prefer a metal framed system over all-wood for weight savings, overall strength, and reduce rattles/squeaks.

I have a fair bit of woodworking experience but no metalworking experience. This is primarily what has held me back.

Your proposed set up of a simple design sounds perfect. All I'm looking for is a very basic set of drawers and would prefer unfinished so that I can control the finish process myself. I'm picky and if a mistake is made I want it to be my mistake.

I assume that I would be able to add locking slides or other modifications at a later date as I find need. If this is the case then again I think your plan sounds perfect.

If needed I can take precise measurements on my LX. Just pm me.

I've been thinking on a design for about six months now and I'd prefer a metal framed system over all-wood for weight savings, overall strength, and reduce rattles/squeaks.

I have a fair bit of woodworking experience but no metalworking experience. This is primarily what has held me back.

Your proposed set up of a simple design sounds perfect. All I'm looking for is a very basic set of drawers and would prefer unfinished so that I can control the finish process myself. I'm picky and if a mistake is made I want it to be my mistake.

I assume that I would be able to add locking slides or other modifications at a later date as I find need. If this is the case then again I think your plan sounds perfect.

If needed I can take precise measurements on my LX. Just pm me.

Bandit

SILVER Star

I am interested as well. Thread Followed!

I am interested as well, and can beta test. 04 LX470

i'm interested in beta. that said, if you had a kit that got to a point like this (with a top obviously) and didn't do anything in the way of a latch/lock and left that to the buyer to do, you would save on the cost of the unit, allow the end user to chose the method they prefer - i.e. lock, no lock, plastic latch versus steel (these can range from $20 to $100) i think you'd have a winner on your hands.

aaronrules

Coolest person you know!

To everyone that has responded, thank you. There is some good feedback in the thread, and the comments and votes as of 6/27 (50% <$750, 47% <$600, and only 3% <$500) indicate a low cost, basic kit that can be the basis for customizing is worth spending my time to put together and sell. If everyone had been insistent on sub 500, well, as anyone who has built one or read the threads will know, that is extraordinarily difficult or impossible for strength, quality, and a few bucks profit to bother.

To all asking for photos and specs - I totally get it, but please recall this was an early 'test-the-waters' sort of question. I would not want to post pics of my current system because it is me prototyping - extra holes where things moved, gap where something changed design, etc. That said it has been out twice now and scored by the whole family a 10/10 for quiet and usefulness

Based on what I have heard I think I might be able to sell 10-20 of these over the next 2-3 months, so enough interest to justify me burning dollars on tweaking and making more user-friendly.

I plan to offer the unit at cost to up to 3 good quality beta testers, based on who expresses interest in this thread and what rig they drive (I need an LX) as well as plans to use the drawers in the field in the near future. This will be via PM soon.

As for timing, I have a good sliding mechanism now that works great and I have never seen before, but is $$ and I feel obligated to test bearings and slides first to compare - those are the standbys everyone is used to - parts on the way and that'll take a couple weeks. I'll then get a couple kits to beta testers for feedback. THEN I'll post detailed pics, specifications, testing results, installation instructions (so folks can feel comfortable with what is required before they buy), transparent pricing, and open it up for orders.

In general I can tell you the system is built of 15mm, 12mm, and 10mm true 7-layer baltic birch plywood, and extruded aluminum. Many pieces will be cut on a CNC waterjet for accuracy of assembly and minimization of my time. The unit's design is simple and basic - if someone wants cubby pocket slots in the back they can certainly cut and modify before they install based on this solid, basic platform, but I'm not including in order to keep cost, construction, and assembly down for those that do not want them.

The initial units will be unfinished because finishing reduces potential for individual customization just too much, and if I learned one thing looking at a hundred drawer posts and videos it is that 100 people really have 100 specific wants and needs. I *may* consider a finished system based on a group purchase of the same finish type, but suspect no 10 people will be able to agree on what that finish would be

After I build a batch of the whole drawers and refine my shipping, ordering, and supply chain logistics I *may* propose a group buy for half drawers, to be based on the full set, and only built if I hit enough demand.

Finally, and likely of most interest, I continue to track a likely sale price in the $550-$650 range, with production in lots of 10 taking 2-3 weeks each. But I'm not asking you to believe me yet, just stay tuned

Let me know what you need. My 06 LX is begging for drawers and will be very utilized as I already have a bunch of crap back there all the time! Measurements, pics...you name it and I'll do it.

Let me know what you need. My 06 LX is begging for drawers and will be very utilized as I already have a bunch of crap back there all the time! Measurements, pics...you name it and I'll do it.

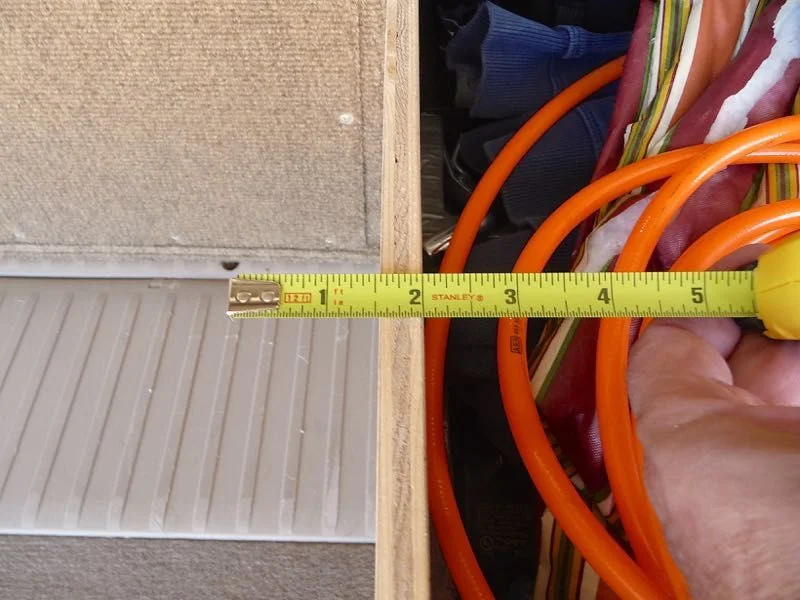

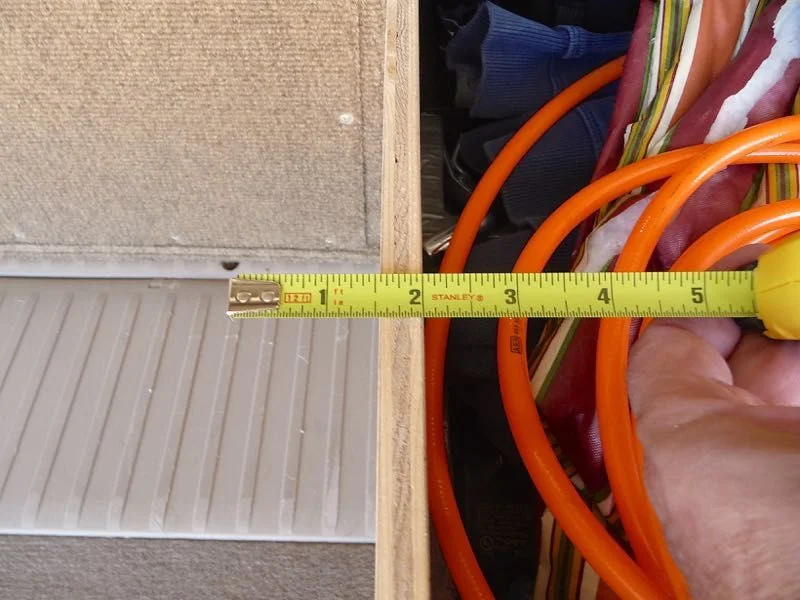

42x40x11 there are the dimensions.

cruzerDave

Land Shark Outfitters

- Thread starter

- #50

@RobRed lol, thanks but I need some dims to bolt holes and holes to sides and such, and to the nearest 1/16"... I'm not there yet and will keep your willingness to help in mind

@therealdutch you are correct in thinking of omitting latches/handles/etc - I bought and tested cheap circular, locking latches, and while they work fine they hurt like heck pulling 100 lbs open. Yes $100 latches would likely be more comfortable and provide security, but a) price, and b) it seems to me that if someone gets through the tailgate that a wooden drawer is not going to stop them either. Metal drawers costing $3000 probably would, but that's not this product. So I'm either going with top hand cutouts or spring-loaded external handles - testing both and trying to decide which balances KISS vs customization against cost, assembly, and user experience best - every little decision is tough!

@therealdutch you are correct in thinking of omitting latches/handles/etc - I bought and tested cheap circular, locking latches, and while they work fine they hurt like heck pulling 100 lbs open. Yes $100 latches would likely be more comfortable and provide security, but a) price, and b) it seems to me that if someone gets through the tailgate that a wooden drawer is not going to stop them either. Metal drawers costing $3000 probably would, but that's not this product. So I'm either going with top hand cutouts or spring-loaded external handles - testing both and trying to decide which balances KISS vs customization against cost, assembly, and user experience best - every little decision is tough!

I’ve never been able to understand the angst about LC100 drawer systems. I took one look at the commercial offerings, decided that >$1,000 did not make sense for me, designed and built my own for a little over $100, and have never looked back.

For context, note that my carpentry and indeed engineering skills are essentially nil. I can glue, drill a hole and screw in a screw and that’s about it. I’m a retired economist (see cost analysis in the previous paragraph). I even used carpet tape for part of this project without realizing that you’re supposed to iron it to activate the glue (I mostly used a 3M spray-on glue not particularly meant for carpets).

My clever trick, if I had one, was to build a prototype out of hot glue and 1/2” thick insulating pink foam sheet, the kind you find in Home Depot, and then use the result as a pattern to get the plywood components to fit precisely. Then, knowing the exact dimensions I needed, I was able to persuade a helpful guy at Home Depot to cut the pieces I needed out of a single 4’ x 8’ sheet of plywood (may have been two sheets, I don't recall for sure).

My critical insight, so to speak, was that because the LC’s rear area with the third row seats removed is essentially flat and the tailgate descends to flat and level and is carpeted, slides are not necessary. They just take up useful space, add cost and add weight. My drawers function perfectly well without them.

The tailgate area inside is not perfectly flat, but I was able to correct for this by screwing an old broom handle across the front of the box that holds the drawers (the front of the box being towards the front of the vehicle). The drawer system is attached in 4 places near the corners to the tie-downs the LC already has in exactly the right places, and is easily removed when I need to reinstall the third row seats, as I did over the Christmas holiday period.

More than a year later I have driven with these drawers loaded up and without a single problem through several Western states, put in thousands of miles on dirt roads and travelled a lot of routes that barely deserve to be called tracks. Two weekends ago for example I drove up La Bajada hill between Santa Fe and Albuquerque, which for those who know it is a rock garden of a road that hasn’t been part of Route 66 since the 1930’s.

My rear drawers have frequently been admired, and function in one respect better than any others I have seen: they are very light weight. That’s critical for me because a key goal has been enhancing my LC’s off-road capability while keeping the suspension totally stock.

Pictures:

My 70lb+ dog sits back here with no problem, often with a pile of luggage beside him:

No slides necessary:

Half inch plywood throughout, plus cheap outdoor carpeting from Home Depot:

Rear anchor point:

Forward anchor point:

The hinged flaps are held up by some wooden Home Depot bookshelf brackets. Not elegant or space-efficient, but as firm as I need them to be:

I keep them pretty loaded up:

Barely over $100! YMMV.

For context, note that my carpentry and indeed engineering skills are essentially nil. I can glue, drill a hole and screw in a screw and that’s about it. I’m a retired economist (see cost analysis in the previous paragraph). I even used carpet tape for part of this project without realizing that you’re supposed to iron it to activate the glue (I mostly used a 3M spray-on glue not particularly meant for carpets).

My clever trick, if I had one, was to build a prototype out of hot glue and 1/2” thick insulating pink foam sheet, the kind you find in Home Depot, and then use the result as a pattern to get the plywood components to fit precisely. Then, knowing the exact dimensions I needed, I was able to persuade a helpful guy at Home Depot to cut the pieces I needed out of a single 4’ x 8’ sheet of plywood (may have been two sheets, I don't recall for sure).

My critical insight, so to speak, was that because the LC’s rear area with the third row seats removed is essentially flat and the tailgate descends to flat and level and is carpeted, slides are not necessary. They just take up useful space, add cost and add weight. My drawers function perfectly well without them.

The tailgate area inside is not perfectly flat, but I was able to correct for this by screwing an old broom handle across the front of the box that holds the drawers (the front of the box being towards the front of the vehicle). The drawer system is attached in 4 places near the corners to the tie-downs the LC already has in exactly the right places, and is easily removed when I need to reinstall the third row seats, as I did over the Christmas holiday period.

More than a year later I have driven with these drawers loaded up and without a single problem through several Western states, put in thousands of miles on dirt roads and travelled a lot of routes that barely deserve to be called tracks. Two weekends ago for example I drove up La Bajada hill between Santa Fe and Albuquerque, which for those who know it is a rock garden of a road that hasn’t been part of Route 66 since the 1930’s.

My rear drawers have frequently been admired, and function in one respect better than any others I have seen: they are very light weight. That’s critical for me because a key goal has been enhancing my LC’s off-road capability while keeping the suspension totally stock.

Pictures:

My 70lb+ dog sits back here with no problem, often with a pile of luggage beside him:

No slides necessary:

Half inch plywood throughout, plus cheap outdoor carpeting from Home Depot:

Rear anchor point:

Forward anchor point:

The hinged flaps are held up by some wooden Home Depot bookshelf brackets. Not elegant or space-efficient, but as firm as I need them to be:

I keep them pretty loaded up:

Barely over $100! YMMV.

Above system is practical, usable, and very well thought out/executed. That being said, because of how I use my setup, it wouldn't fit my needs at all

It perfectly illustrates how hard it's going to be to accomplish the goal set forward in this thread. For some reason, the drawer system setups in the 100 series seem to be a highly personal, custom setup for each and every owner. I hope @cruzerDave can get it figured out, because i do think there is a need.

It perfectly illustrates how hard it's going to be to accomplish the goal set forward in this thread. For some reason, the drawer system setups in the 100 series seem to be a highly personal, custom setup for each and every owner. I hope @cruzerDave can get it figured out, because i do think there is a need.

cruzerDave

Land Shark Outfitters

- Thread starter

- #53

@ntsaint - agreed, at times I think it might've been easier to create a new religious political party than a drawer system!

@Desert100 that's a real nice, simple system - good job. I think you oversell your capabilities though, as getting drawers perfectly square, drilling dozens of screws into 1/2" plywood without splitting, and even knowing which plywood to use or that HD folks will cut for you is not an across-the-board skillset. I am trying, by stripping back to the minimum necessary and designing a unique frame, to be the solid starting point for folks without table saws, woodworking experience, time, or design acumen. One question, you mention it being light but I see an awful lot of 1/2" plywood, what does it weigh empty? (and good job nuking slides, those things are HEAVY)

Finally, I want to collect customizations from users on a webpage with helpful links to purchase options (not through me, this is not my biz) for people to get design inspiration or jump-start their own projects. I think it would be pretty cool to have a place to go and see a recessed bottle opener (for example) or two, and links to go buy them. Searching through drawer threads can be a massive time suck

@Desert100 that's a real nice, simple system - good job. I think you oversell your capabilities though, as getting drawers perfectly square, drilling dozens of screws into 1/2" plywood without splitting, and even knowing which plywood to use or that HD folks will cut for you is not an across-the-board skillset. I am trying, by stripping back to the minimum necessary and designing a unique frame, to be the solid starting point for folks without table saws, woodworking experience, time, or design acumen. One question, you mention it being light but I see an awful lot of 1/2" plywood, what does it weigh empty? (and good job nuking slides, those things are HEAVY)

Finally, I want to collect customizations from users on a webpage with helpful links to purchase options (not through me, this is not my biz) for people to get design inspiration or jump-start their own projects. I think it would be pretty cool to have a place to go and see a recessed bottle opener (for example) or two, and links to go buy them. Searching through drawer threads can be a massive time suck

like this? half drawer w/ cupholder integrated for 3rd row passenger...

I guess there's alot of truth in the idea that we all have different expectations on what we'll use drawers for. One of the most desireable features for me was the ability to get access with out having to unpack your gear. So top access would not be necessary (except for maintenance). Also, for me, as little as possible, more room for storing camping chairs, tents & gear or luggage on top. Just a place to stow jacks, chains, snatch block, D-shackles, tools, spare parts, etc.... These things need to be accessible at all times, so you can't just put them on top of all your other gear that's packed, because they're heavy and dirty and would settle to the bottom anyway. You'd be hunting for them forever. So for me strength and reliability in the drawers is non-negotiable. I tried a couple of plywood and plastic bin setups that left me unsatisfied. Plastic and wood didn't fill my purpose, plus I wanted a fridge and slide setup. I didn't want an impressive storage unit stacked in the back with edges following the contours - like it appears is popular. My minimum Outback Solutions works perfect for my purposes and you might consider as a basic setup option model, Dave.

Last edited:

I have an 07 LC definitely need a drawer system in the rear. I would absolutely be interested in a kit.

Hello Dave. Pm sent.

I'm watching this as a competitor and am excited to see what you come up with!

Your materials sound similar to mine and I think we're aiming for a similar price point. The Cruiser market might be flush with options soon where there's currently a big black hole, haha!

Your materials sound similar to mine and I think we're aiming for a similar price point. The Cruiser market might be flush with options soon where there's currently a big black hole, haha!

cruzerDave

Land Shark Outfitters

- Thread starter

- #59

@suprarx7nut even if you hadn't said you were a competitor I would've known from your name.

I still drive my modified 1997 TSi AWD.

As there are only so many ways to skin a cat, this should be interesting!

I still drive my modified 1997 TSi AWD.

As there are only so many ways to skin a cat, this should be interesting!

cruzerDave

Land Shark Outfitters

- Thread starter

- #60

My latest prototype of a user-friendly way to assemble drawers [SQUARELY] from a kit... KICKS BUTT!

*DONE*

Well, done except for making 2 key design decisions... both work but I have to choose one. I've PM'd some of you for your opinions, and your answers in the next day or two are greatly appreciated.

I will then do one final proto to make sure the waterjet program is correct, then contact the betas.

THIS IS HAPPENING

*DONE*

Well, done except for making 2 key design decisions... both work but I have to choose one. I've PM'd some of you for your opinions, and your answers in the next day or two are greatly appreciated.

I will then do one final proto to make sure the waterjet program is correct, then contact the betas.

THIS IS HAPPENING

Similar threads

- Replies

- 5

- Views

- 378

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)