I searched and surprisingly did not find much info on this

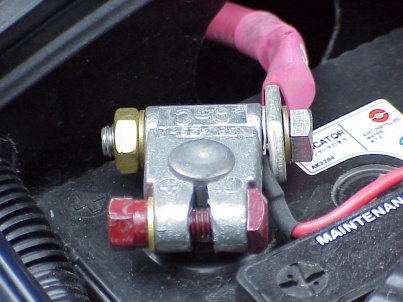

I am installing a second battery soon. For now I am looking at using 2/0 cable for both the second battery and to replace the stock cables. Built for a 200A continuous draw, I plan to add a winch later on as funds allow

I have crimped my battery cables in the past and they worked just fine, but I am also considering soldering these,

I did some googling on the subject and there is no consensus, lots of pro’s and con’s for both,

Pro’s

Crimp

Direct copper to copper contact

Hi strength will not pull or vibrate out

Solder

Large conductive contact area (100 %)

Air and water are sealed out

Con’s

Crimp

Not sealed from oxygen and water. Will eventually corrode

Lower contact area

Solder

Solder is not as good a conductor as copper

Lower strength, can rattle out over time

Possible insulation damage from the heat

Hard not to get a cold joint with such large pieces to heat

I can crimp and then solder Or I can crimp and do my best with heat shrink and dielectric grease to seal it up, both negate some of the cons but not all

What makes the most reliable/conductive cable? I think either way I am going to crimp, the question is do I solder after? Is there a tool I can rent to evenly compress (swage ) terminals on to a cable as opposed to the press/hammer a dent in the middle crimpier?

I am installing a second battery soon. For now I am looking at using 2/0 cable for both the second battery and to replace the stock cables. Built for a 200A continuous draw, I plan to add a winch later on as funds allow

I have crimped my battery cables in the past and they worked just fine, but I am also considering soldering these,

I did some googling on the subject and there is no consensus, lots of pro’s and con’s for both,

Pro’s

Crimp

Direct copper to copper contact

Hi strength will not pull or vibrate out

Solder

Large conductive contact area (100 %)

Air and water are sealed out

Con’s

Crimp

Not sealed from oxygen and water. Will eventually corrode

Lower contact area

Solder

Solder is not as good a conductor as copper

Lower strength, can rattle out over time

Possible insulation damage from the heat

Hard not to get a cold joint with such large pieces to heat

I can crimp and then solder Or I can crimp and do my best with heat shrink and dielectric grease to seal it up, both negate some of the cons but not all

What makes the most reliable/conductive cable? I think either way I am going to crimp, the question is do I solder after? Is there a tool I can rent to evenly compress (swage ) terminals on to a cable as opposed to the press/hammer a dent in the middle crimpier?

You see, I know for a fact that you do not have a receipt...

You see, I know for a fact that you do not have a receipt...