- Thread starter

- #221

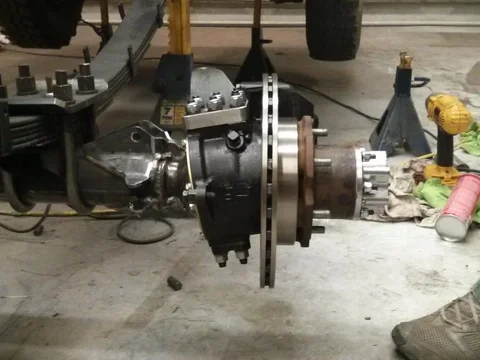

With the cut widened (basically the width of a grinding disc) you can clearly see a concentric ring where the housing and the sleeve of the ball meet. For those interested, that ring is precisely at a depth of 6 mm. Once we made a couple of touch up cuts where that ring was not visible, the ball finally turned.

The conclusion was that we cut too close to the middle of the factory weld and never really separated the material. The final touch up cuts were towards the diff. We also cut too deep (for those keeping score).

On the passenger side ball, this process was used:

With a cut off wheel, cut a groove on the diff side of the factory weld (not in the center of the weld in any way) just deep enough to see after the housing is ground smooth.

Grind off the factory weld bead so the housing is smooth all the way around.

Go back and take the initial cut to a depth of 6 mm.

Open up that cut to the width of a grinding disc.

At this point you could see the difference in the housing and ball sleeve material. I took the cut off wheel and cut just a hair deeper all the way around. With a little force and no heat, this ball turned right away. After a very tough learning process on the driver's side ball, the passenger side was pretty easy.

The conclusion was that we cut too close to the middle of the factory weld and never really separated the material. The final touch up cuts were towards the diff. We also cut too deep (for those keeping score).

On the passenger side ball, this process was used:

With a cut off wheel, cut a groove on the diff side of the factory weld (not in the center of the weld in any way) just deep enough to see after the housing is ground smooth.

Grind off the factory weld bead so the housing is smooth all the way around.

Go back and take the initial cut to a depth of 6 mm.

Open up that cut to the width of a grinding disc.

At this point you could see the difference in the housing and ball sleeve material. I took the cut off wheel and cut just a hair deeper all the way around. With a little force and no heat, this ball turned right away. After a very tough learning process on the driver's side ball, the passenger side was pretty easy.