I see a lot of people balking at the idea of soaking their upper intake in Simple Green, saying that it attacks aluminum. So I did a test, then forgot to post about it. I put a section of 1/8" thick aluminum into a container of undiluted Simple Green on 4/19 at 5:44pm. I used a Scotchbrite disc to knock off any anodization on the back side.

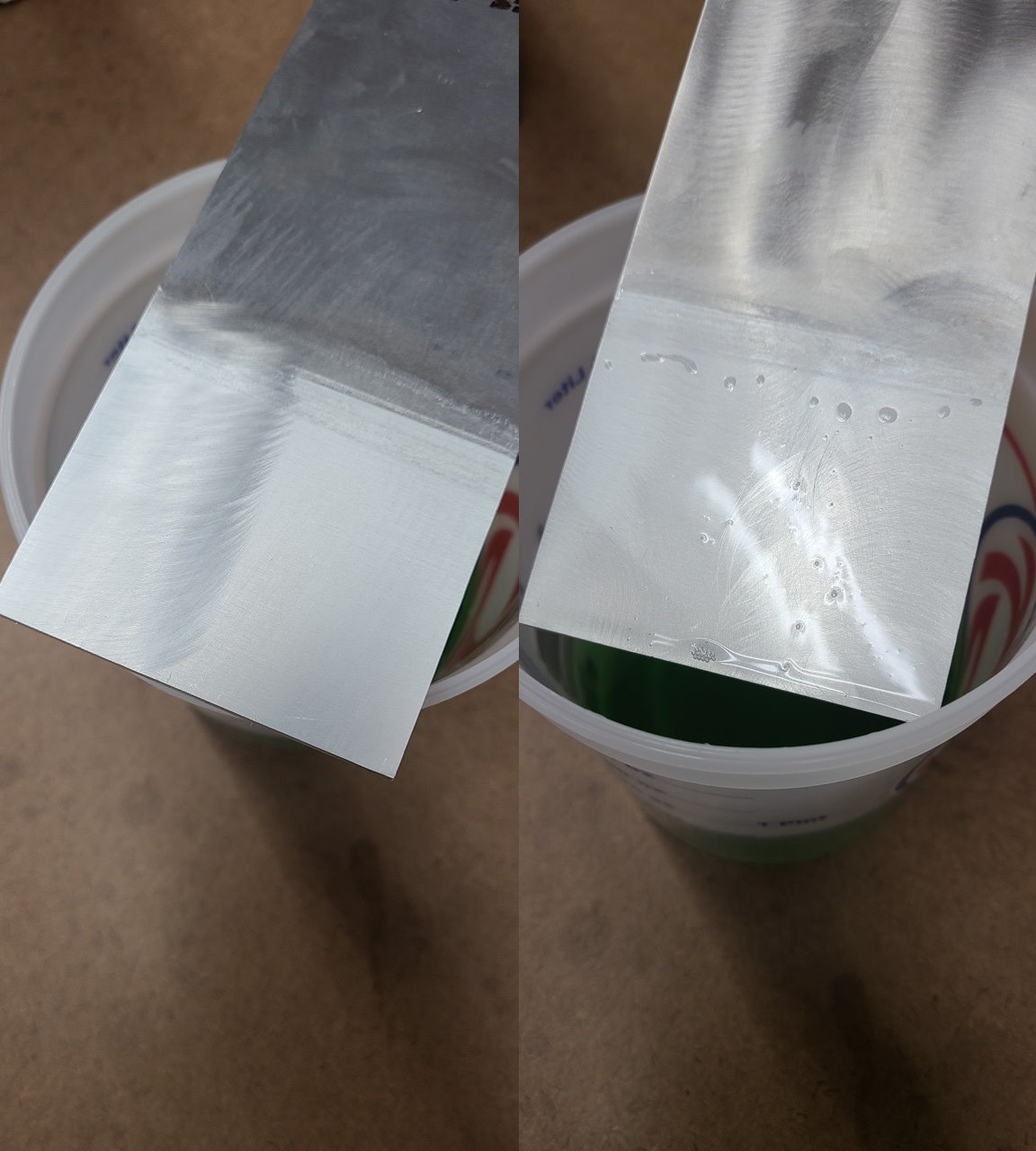

Here it is after a little over three hours:

Here it is after around 28 hours:

Some discoloration is happening.

Here it is after around 75 hours:

At this point, I ran a Scotch-brite disc down the left side, just to see how deep the discoloration was. It wasn't deep at all and polished right up:

Finally, here it is after 118 hours:

At no point was there any measurable loss of material. It measured 0.1220" thick at the start, and 0.1220" thick at the end.

So, will Simple Green discolor your raw, polished aluminum rims? Yes. Will it dissolve or damage your upper intake? No.

Here it is after a little over three hours:

Here it is after around 28 hours:

Some discoloration is happening.

Here it is after around 75 hours:

At this point, I ran a Scotch-brite disc down the left side, just to see how deep the discoloration was. It wasn't deep at all and polished right up:

Finally, here it is after 118 hours:

At no point was there any measurable loss of material. It measured 0.1220" thick at the start, and 0.1220" thick at the end.

So, will Simple Green discolor your raw, polished aluminum rims? Yes. Will it dissolve or damage your upper intake? No.