Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Heat riser Block off plate

- Thread starter LandoNick

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

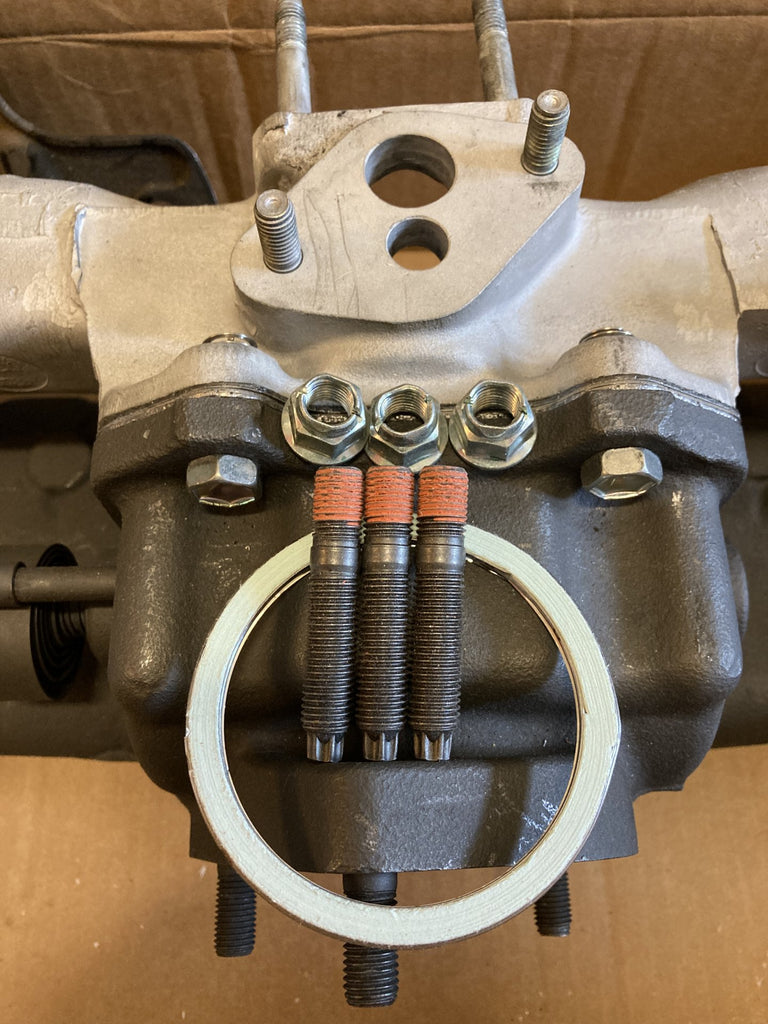

Who Replied?Ah yeah, Remflex gaskets are thicker. I must have missed that somewhere in the thread. I think a quick eyeball check on how the half-holes are lining up is all that's needed. Not quite there yet? Add another gasket. Already there? Leave it alone.Its more a case of a stock gasket vs the remflex gasket. If you are using the stock thinner gaskets then 2 gaskets and the plate is probably right. The reflex i thicker. I have a photo I can post from my phone later.

In my photo the remflex gasket before it’s torqued is easily 4x the thickness of the block off plate.So heat diffuser (I guess I will call it) and the block off plate are the same thickness. Yes the Reflex I'm sure are thicker. but double? I have old stock smashed gaskets not sure if that will help me.

The best solution to all this…3fe exhaust manifolds.

- Thread starter

- #27

I guess thinking about it. the "door: would just stop on the block off plate. Any risks there?What is the best way to trim the rotating door inside the manifold? I feel anyway you do it metal will be in there, I would like to avoid that.

You can 'lock' the flap in the open position with the block off plate, but if you want the least exhaust restriction, best to remove the flap, but then you will have to weld up the hole left by the shaft the flap attaches to, as that falls out when the flap is removed.

Some have tapped for pipe plugs

forum.ih8mud.com

forum.ih8mud.com

Some have tapped for pipe plugs

exhaust manifold leak at the heat riser bushings

forum.ih8mud.com

forum.ih8mud.com

Somebody on here had the holes for the shaft threaded and stuck some tapered plugs in there. One of my longer term projects is to have a manifold set machined to perfection, and part of that will be tapping those holes and installing plugs. I think if you want to get rid of the heat riser functionality the best solution is to completely get rid of the whole thing - which of course leads to other problems that need solving, like two giant holes in the side of the exhaust manifold.You can 'lock' the flap in the open position with the block off plate, but if you want the least exhaust restriction, best to remove the flap, but then you will have to weld up the hole left by the shaft the flap attaches to, as that falls out when the flap is removed.

Some have tapped for pipe plugs

exhaust manifold leak at the heat riser bushings

forum.ih8mud.com

- Thread starter

- #30

How does one "lock" it open? Is the blade just riveted on the shaft? looks like it, but not for sure.You can 'lock' the flap in the open position with the block off plate, but if you want the least exhaust restriction, best to remove the flap, but then you will have to weld up the hole left by the shaft the flap attaches to, as that falls out when the flap is removed.

Some have tapped for pipe plugs

exhaust manifold leak at the heat riser bushings

forum.ih8mud.com

Rotate it to the open position and hold it there while you install the block off plate and bolt the two halves together. The plate restricts the flap's movement so it can never go "closed" again.How does one "lock" it open? Is the blade just riveted on the shaft? looks like it, but not for sure.

You can 'lock' the flap in the open position with the block off plate, but if you want the least exhaust restriction, best to remove the flap, but then you will have to weld up the hole left by the shaft the flap attaches to, as that falls out when the flap is removed.

Some have tapped for pipe plugs

exhaust manifold leak at the heat riser bushings

forum.ih8mud.com

This is absolutely @Seth S and @Spike Strip area of intense experience from a life long oppressive regime out in the CA. Emissions package

.

Both have helped me tackle and then update the related OEM japan spec. Special Service parts now a staple main stay from

The NON-USA far-away …

1/75 -1987 FJ40 / FJ60 Exhaust Down PIPE Repair Kit #1 OEM TOYOTA Genuine Parts FJ60 2F Engine Updated / Upgraded Exhaust Manifold to Front Down Pipe Gasket and Special Unique Hardware TORX STuds and Locking Flange Nuts - VintageTEqParts.com

OEM TOYOTA Genuine Parts FJ60 2F Engine Updated / Upgraded Exhaust Manifold to Front Down Pipe Gasket and Special Unique...

vintageteqparts.com

Carbon Steel 2F Exhaust Manifold Flange Down PIPE KIT 1/75 -1987 FJ40 FJ60 FJ55 OEM TOYOTA Genuine Parts Updated Upgraded Special Unique Hardware TORX STuds and Locking Flange Nuts ( 3-BOLT FLANGE WATER JETTED IN-HOUSE ) - VintageTEqParts.com

OEM TOYOTA Genuine Parts FJ60 2F Engine Updated / Upgraded Exhaust Manifold to Front Down Pipe Gasket and Special...

vintageteqparts.com

As @Spike Strip puts it often , he is using modern materials with a purist based mindset approach philosophy….

As @Spike Strip puts it often , he is using modern materials with a purist based mindset approach philosophy….

Never! I'm cheap!

How does one "lock" it open? Is the blade just riveted on the shaft? looks like it, but not for sure.

Rotate it to the open position and hold it there while you install the block off plate and bolt the two halves together. The plate restricts the flap's movement so it can never go "closed" again.

What ^^ he said. The flap position so exhaust is directed DOWN the down pipe.

- Thread starter

- #34

Its seems that what I rotate it "open" with spring at max tension. It almost blocks the path more or the same as it sits at rest. I could be off.Rotate it to the open position and hold it there while you install the block off plate and bolt the two halves together. The plate restricts the flap's movement so it can never go "closed" again.

So heat diffuser (I guess I will call it) and the block off plate are the same thickness. Yes the Reflex I'm sure are thicker. but double? I have old stock smashed gaskets not sure if that will help me.

guess what NICK ,

in T-TEN college , we had a dyno , this was before SOR invented the stainless block off plate

in ENGINES building class senior year i hand rebuit my 12/78 2F engine out of my FJ40 below

- my professor Bob EYELER suggested i completely REMOVE the shaft and flapper ,

- i was going to MIG WELD it OPEN via the SHAFT to the TITANIOUM Collar Bushings pressed into each side of butterfly shaft

- Professor Eyler told me i would BOTH run a cooler exhaust manifold and gain a notable HP increase , by removing the OPEN positioon RESTRICTION of the round shaft and the butter fly shaft all together

EXAUST AIR gets out faster = intakes faster RIGHT !

well if you do not know the answer IS YES ...

- cooler manifold = cooler engine bay all around too

- take TWO M10 x 16mm HEX HEAD OEM bolts , NO SEMS WASHERS , NO FLANGE head either to be clear here

- DO NOT pre heat manifold before mig welding , your focus point is iside corner of titainum berring and carbon steel bolt

- MIG WELD ALL in ONE goot pass all around

DONE

- presto INSTANT PONIES YOU CAN INDEED FEEL , i S#HIT YOU NOT this is very real

your entire engine bay vintage parts , wires pipes etc , is now being better preserved / LESS HEAT period !

THIS IS THE WAY ..........

Last edited:

When I fixed mine big Exhaust leaking coming from shaft bushings of flap. So I completely removed flap and shaft. I followed the lead of post #16 in this thread.Its seems that what I rotate it "open" with spring at max tension. It almost blocks the path more or the same as it sits at rest. I could be off.

exhaust manifold leak at the heat riser bushings

forum.ih8mud.com

forum.ih8mud.com

- Thread starter

- #37

How exactly do you remove that shaft? I'm an idiot so more detail the better.When I fixed mine big Exhaust leaking coming from shaft bushings of flap. So I completely removed flap and shaft. I followed the lead of post #16 in this thread.

Mine not as elegant but has worked great So far. No more Exhaust leak

exhaust manifold leak at the heat riser bushings

forum.ih8mud.com

If I remember, once I removed the flapper off, the shaft on mine pretty much fell out. Mine was leaking pretty bad from both bushings on either end of shaft. I do remember I had to cut the flapper off shaft for shaft to come out and the spring controller on the one end of the shaft (don’t know technical name) had to be removed too. I don’t remember it being difficult. Sorry if none of this helps, my Technical Jargon is seriously lacking.How exactly do you remove that shaft? I'm an idiot so more detail the better.

- Thread starter

- #39

And to remove the Flapper, cut the welds?If I remember, once I removed the flapper off, the shaft on mine pretty much fell out. Mine was leaking pretty bad from both bushings on either end of shaft. I do remember I had to cut the flapper off shaft for shaft to come out and the spring controller on the one end of the shaft (don’t know technical name) had to be removed too. I don’t remember it being difficult. Sorry if none of this helps, my Technical Jargon is seriously lacking.

Yes , I used dremel with a cut off blade because of space.And to remove the Flapper, cut the welds?

Similar threads

- Replies

- 5

- Views

- 793

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)