- Joined

- Sep 26, 2003

- Threads

- 117

- Messages

- 11,199

- Location

- Lancaster, Ohio, USA

- Website

- www.tlcperformance.com

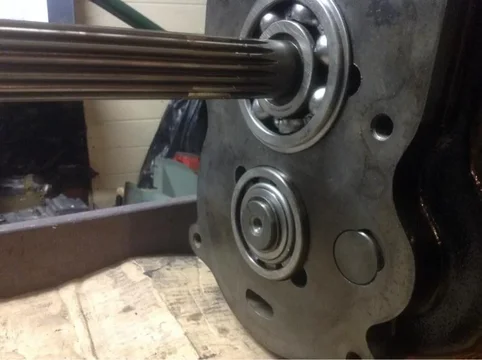

Pin is saying if there is enough room to drop on the bearing washer & install lock ring, then it is good.

Looking at the pichers, I'm pretty sure it is all the way on there. The shoulder of the bearing does not go against the gear teeth. It hits a radiused shoulder on the shaft about 1/8" away from the gear teeth.

Looking at the pichers, I'm pretty sure it is all the way on there. The shoulder of the bearing does not go against the gear teeth. It hits a radiused shoulder on the shaft about 1/8" away from the gear teeth.