78fj40mg

TLCA #23510

Hey all,

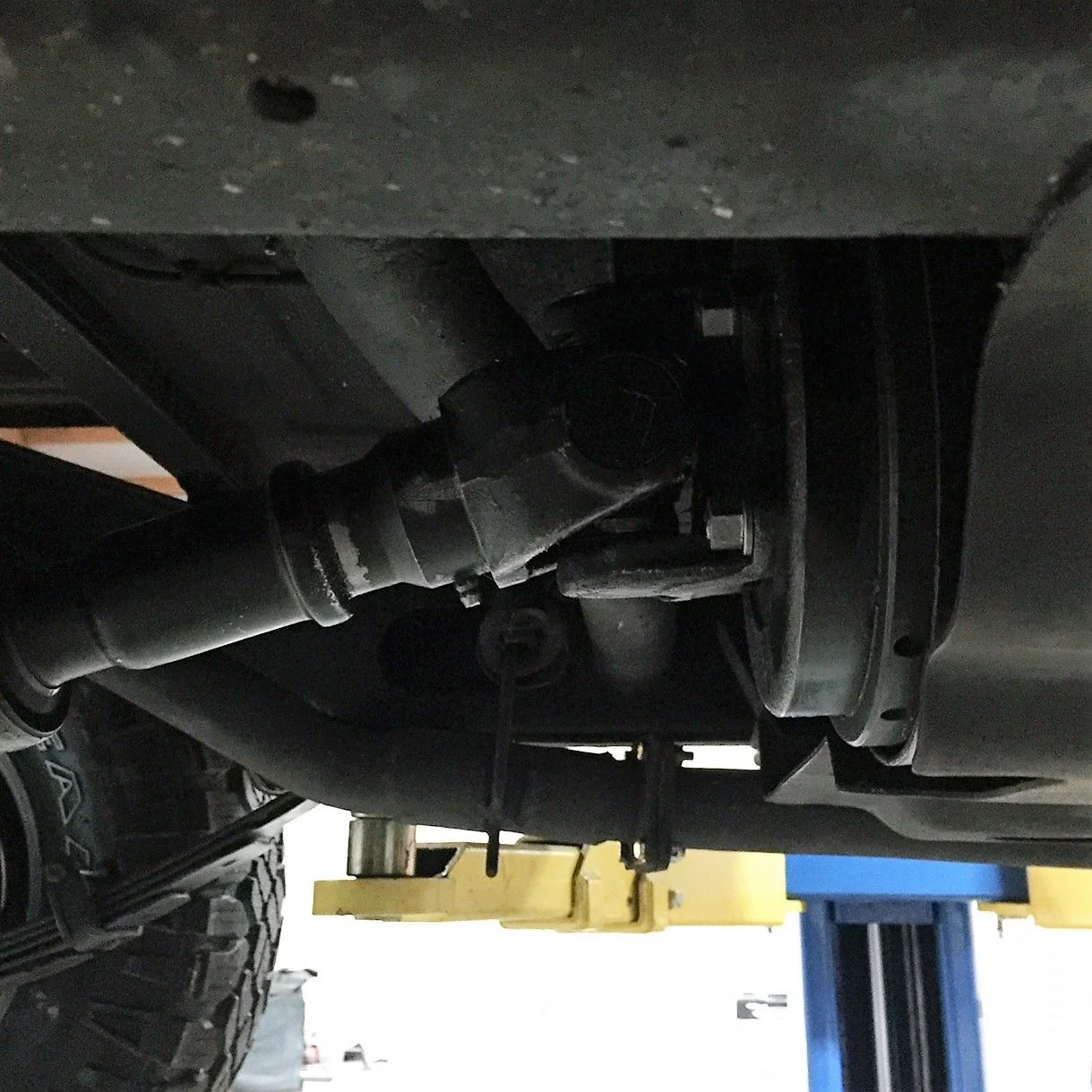

My rear drive line angle has been bad ever since I installed the new OME Medium Duty suspension, 2.5 inch lift, and I've been getting some vibration coming from the rear end. I had some time today so I checked the angles with all four wheels firmly on level ground, the results were based on the TREMEC Drive Line Angle finder iPhone app:

These TREMEC readings were not correct maybe it was my fault.

See my accurate readings bellow using an angle finder

Angle 1. at the parking brake was 08.01 Down

Angle 2. at the drive shaft was 12.2 Down

Angle 3. at the 3rd member flange and the drive line angle was calculated to be 04.2 Down

Am I correct to assume that it needs to be raised 4.2 degrees?

Should I use a 3, 4 or 5 degree shim?

I don't want to over or under compensate the angle deficiency.

Thanks in advance for your valuable input!

My rear drive line angle has been bad ever since I installed the new OME Medium Duty suspension, 2.5 inch lift, and I've been getting some vibration coming from the rear end. I had some time today so I checked the angles with all four wheels firmly on level ground, the results were based on the TREMEC Drive Line Angle finder iPhone app:

These TREMEC readings were not correct maybe it was my fault.

See my accurate readings bellow using an angle finder

Angle 1. at the parking brake was 08.01 Down

Angle 2. at the drive shaft was 12.2 Down

Angle 3. at the 3rd member flange and the drive line angle was calculated to be 04.2 Down

Am I correct to assume that it needs to be raised 4.2 degrees?

Should I use a 3, 4 or 5 degree shim?

I don't want to over or under compensate the angle deficiency.

Thanks in advance for your valuable input!

Last edited: