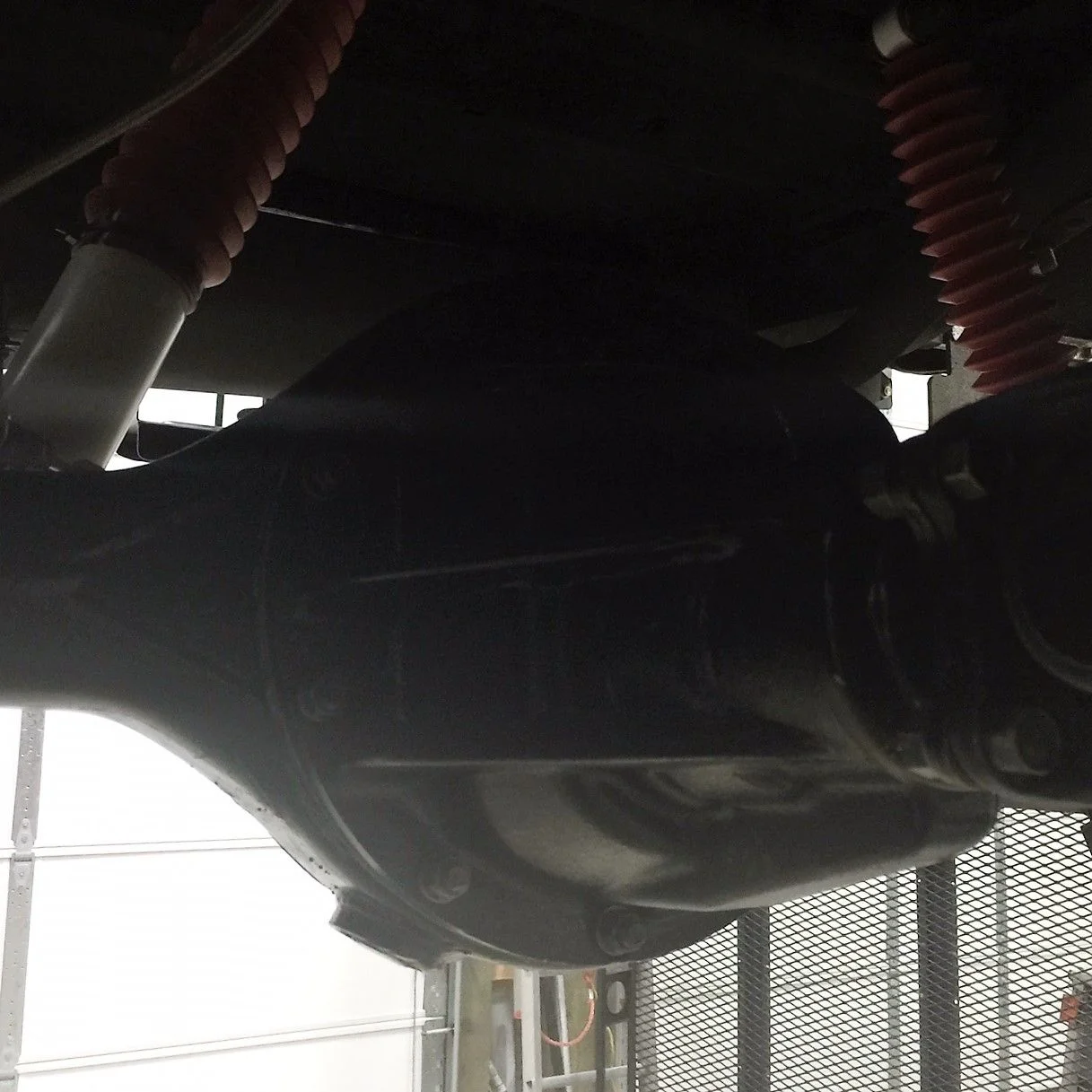

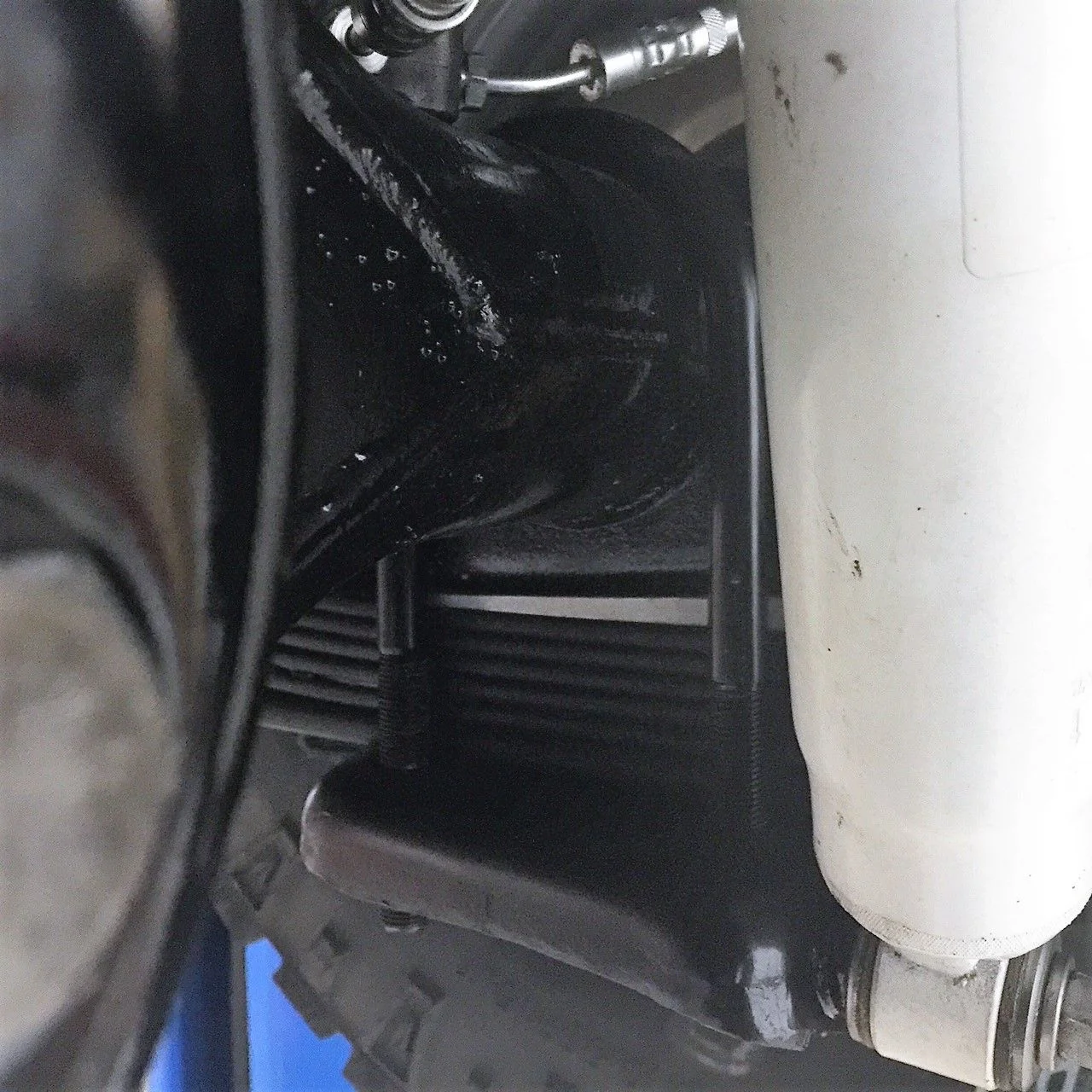

Random thought: are the rear springs on the correct way around? Front to front and rear to rear. Is there a correct orientation? Might that make the rear pinion angle worse with the new (longer) rear shackles?

Does the vibration get worse with increasing vehicle speed (usually driveline angularity)? Or is it pretty much the same at all speeds (maybe some other cause)?

Does the vibration get worse with increasing vehicle speed (usually driveline angularity)? Or is it pretty much the same at all speeds (maybe some other cause)?