Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Doible flare brake lines and i still have leaks

- Thread starter chubot

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?Sometimes you have to tighten them down a little more then you think. I would assume there is some torque spec. How bad are they leaking, a leak or just a little coming out.

How is the receiving (female) end look?

Tighten the s*** out of it.................................

I just went through something like this with mine. I made a line to replace one that got rusty between the master cylinder and a valve/junction block mounted to the booster. It leaked on the end I re-flared. Made another one, that one leaked too. Bought one premade from napa roughly the same length and bent it to fit. That one doesn't leak. First time I ever had a problem with lines I made with that tool leaking. Drove me nuts for a while.

- Thread starter

- #8

Poser said:Should not be the issue.

What month/year truck are you working on?

It's a 78 I'll have to get back with you on month

- Thread starter

- #9

cjgoode said:Sometimes you have to tighten them down a little more then you think. I would assume there is some torque spec. How bad are they leaking, a leak or just a little coming out.

After I started the bleed down process the line from the junction block on right side of front axel to the soft line. Both ends are a steady drip.

Cross threaded ?

- Thread starter

- #11

3DAMAN! said:Cross threaded ?

Don't think so, I started them and turned them in a few turns before backing them out to check for cross threads.

- Thread starter

- #12

shelfboy1 said:napa sells 2 different style flares regular and double ,i have always used the double flare on mine ,tighten them as tight as you can .ive never had one leak.

I think I have it tightened pretty good and I don't believe I cross threaded. It might just be a badly flared line. None of the others are leaking at this point and it's a steady drip coming out of the line where it meets the junction. Lock.

It's a 78 I'll have to get back with you on month

That is fine; I just wanted to know that you were working on 10x1.0 fittings and not something else...

So the line/fitting that is leaking, can you turn the b-nut on the line any more?

Are you using flare nut wrenches?

(generic photo, I am not insinuating using ASE wrenches on metric fittings)

.

1973Guppie

Supporting Vendor

one note on flaring, I was told by a friend that when cutting the line before you make the flare, use an angle grinder and NOT the little cutting wheel. The little cutting wheel will work harden the metal material and make it harder to get a good flare. I always now cut with a grinder and then flare the tube and it makes a big difference. My guess is that you are just not getting a good flare. I usually have to try 2 or 3 times to get a good flare.

HTH, Noah

HTH, Noah

one note on flaring, I was told by a friend that when cutting the line before you make the flare, use an angle grinder and NOT the little cutting wheel. The little cutting wheel will work harden the metal material and make it harder to get a good flare. I always now cut with a grinder and then flare the tube and it makes a big difference. My guess is that you are just not getting a good flare. I usually have to try 2 or 3 times to get a good flare.

HTH, Noah

I had never heard that. Perhaps that's my problem and I'm sure my cutter has seen better days by now anyhow. I have to make all new lines for my Capri project so I'll certainly try cutting with a grinder instead.

brooklyn

SILVER Star

leakes

Just finished my brakes - 9mm to 10mm, before I began flarring i looked at a bunch of videos on youtube to see how it is done.

After I installed everything I had leaks all over the place and I had to tighten everything down - way more than I expected. I thought my flares were an issue and did reflare a few, but those leaked as well until i tightend them.

I would suggest using the wrenches picured below by poser.

Good luck.

Just finished my brakes - 9mm to 10mm, before I began flarring i looked at a bunch of videos on youtube to see how it is done.

After I installed everything I had leaks all over the place and I had to tighten everything down - way more than I expected. I thought my flares were an issue and did reflare a few, but those leaked as well until i tightend them.

I would suggest using the wrenches picured below by poser.

Good luck.

Use the proper wrenches for sure, makes a huge difference on how much torque can be applied to the fittings.

I've found a huge difference in flare quality depending upon what flaring tool is used - Matco's kit is by far better than any other I've found other than the really expensive hydraulic units -

DFS260A DOUBLE FLARE TOOL SET | Matco Tools

The key to this kit is the way the H-frame clamp works, it has cutouts that keep it centered over the line end when flaring . Other brands can be slightly off-center and don't produce a solidly centered flare ring -this results in leaks. I've made several hundred ends with this kit , both on new line and used old lines and never had a leak issue ....

Sarge

I've found a huge difference in flare quality depending upon what flaring tool is used - Matco's kit is by far better than any other I've found other than the really expensive hydraulic units -

DFS260A DOUBLE FLARE TOOL SET | Matco Tools

The key to this kit is the way the H-frame clamp works, it has cutouts that keep it centered over the line end when flaring . Other brands can be slightly off-center and don't produce a solidly centered flare ring -this results in leaks. I've made several hundred ends with this kit , both on new line and used old lines and never had a leak issue ....

Sarge

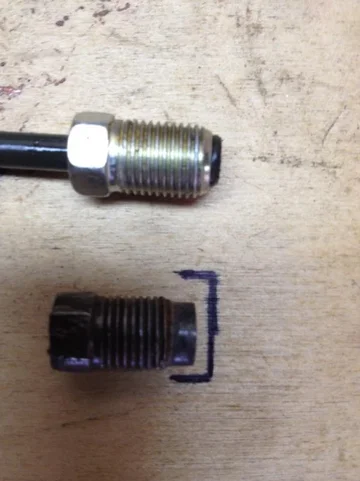

Sometimes the female fitting is the culprit. If you look down inside, they will have a raised portion -- a "cone", so to speak -- that mates with the flared end of the tubing. This can get damaged or smashed/worn down. Then, the outer edge of the tube flare is what makes contact instead of the flared portion and they may leak. I had to replace the fitting to get it to stop. This was not on a FJ, so just a thought to consider.

I always use the little cutting tool, I just put a little pressure at a time and turn it a lot. If you turn the knob to tight to cut it quicker you can get an angle on the tube and less of a straight cut. Mine has a little tool to run inside and remove any burs. I cannot picture getting a clean straing cut with an angle grinder, but never tried.

one note on flaring, I was told by a friend that when cutting the line before you make the flare, use an angle grinder and NOT the little cutting wheel. The little cutting wheel will work harden the metal material and make it harder to get a good flare. I always now cut with a grinder and then flare the tube and it makes a big difference. My guess is that you are just not getting a good flare. I usually have to try 2 or 3 times to get a good flare.

HTH, Noah

ooohh

the student has now become the teacher

Similar threads

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)