This thread is not quite a comprehensive fix (yet), but hopefully gets the ball rolling to improve upon fuel venting/boiling in the 200-series. I don't have complete answers and hoping there will be continued contributions by the hive mind. This is one of those issues that may not have a single magic bullet fix. It's a balance of use cases and mods that exacerbate getting heat into the fuel system versus mitigations sufficient to overcome heating factors.

There's some other variables to this. Fuel composition and added ethanol can contribute to the volatility of fuel. Short answer is its best to avoid ethanol compositions that has allowances for higher RVP, buy fuel from stations at higher elevation, use high octane that is inherently less volatile, and fill tanks to higher levels to increase thermal mass. Stock rigs can experience this. Aftermarket modifications like skids, aux gas tanks, and even bumpers can exacerbate the issue, disrupting cooling airflow, trap heat, and increase heat input to the fuel system. Many rigs experience this but perhaps the cruiser series is particularly susceptible as the driveline and gas tank tends to be tucked up higher and tighter under the chassis trapping more heat.

This is not an all or nothing, with each added mitigation potentially buying more margin to managing fuel venting/boiling. It's fully possible the issue can't be fully solved but added margin is worth the effort IMO.

1. Fuel tank shielding

a. Aux tank shielding

2. Fuel line shielding around exhaust

3. Fuel line shielding around engine

4. Fuel cooler

Amazon product ASIN B000CEM3O0

Need 3/8 and 5/8" wraps

Amazon product ASIN B079S1XLM7

Synopsis of Problem

Fuel has increased volatility and vapor pressure known as Reid vapor pressure (RVP), at elevated temperature or reduced atmospheric pressure, or a combination of both. Commonly experienced when slow crawling on trails with minimal airflow and lots of heat soak, combined with trails at 6k+ ft elevation. To the point that fuel vapors can vent and actually boil. The only thing we can really control is heat input into the fuel. If someone were inclined to instrument the problem, it is singularly fuel temperature to be watched and managed.There's some other variables to this. Fuel composition and added ethanol can contribute to the volatility of fuel. Short answer is its best to avoid ethanol compositions that has allowances for higher RVP, buy fuel from stations at higher elevation, use high octane that is inherently less volatile, and fill tanks to higher levels to increase thermal mass. Stock rigs can experience this. Aftermarket modifications like skids, aux gas tanks, and even bumpers can exacerbate the issue, disrupting cooling airflow, trap heat, and increase heat input to the fuel system. Many rigs experience this but perhaps the cruiser series is particularly susceptible as the driveline and gas tank tends to be tucked up higher and tighter under the chassis trapping more heat.

Solution Template

@J1000 gets credit for analysis and identification of tested mitigations for the 100-series. Short of that being available for the 200-series, and with the 200-series sharing many of the same layout and design aspects, this should be a great template to follow. Worth a read and it gives us a strong clue as to which mitigations may contribute the most.I was under my truck doing some more mods. And since I have a fuel temperature sensor, I can tell what works and what doesn't. If you want to argue with me then just put me on ignore, please. If you want to prove me wrong, get your own fuel temperature sensor. Here's two good ones: Amazon.com: Innovate Motorsports 3904 MTX-D Dual Gauge Kit -Ethanol/Fuel Temp, 1 Pack: Automotive and Amazon.com: Zeitronix ECA-2 Ethanol E% Content Analyzer Kit with Blue Display Gauge: Automotive If you have constructive criticism, please post it.

Reminder, this thread is about boiling fuel. Your #1 point of reference should be the fuel's temperature. Everything else is secondary. No, I do not expect everyone to have fuel temperature because it's not available stock or without some elbow grease but I've got one.

The following are my mods to combat fuel temperature in order of their effectiveness. I have also done lots of work on my evap system which I've detailed in this thread: 100 Series Charcoal Canister Replacement Truck is well maintained and has many new parts over the last 1-2 years, too many to list but if you are thinking "but did you replace your _____" the answer is probably YES!

#1: Extensive heat shielding. Earlier in this thread there was talk about extra shielding on the catalytic converters, but I found recently over the past few weeks that there are far more important areas to add heat shielding. I've been doing this by driving a lot and then scooting under the truck on my creeper and feeling around with my hands and figuring out where things are hot and where they aren't and then doing it again.

There is an area here on the fuel tank where the stock metal guard doesn't cover and there is no heatshield between it and the exhaust pipe.

Bare fuel tank exposed within 12" of exhaust pipe (darker tank shield seen below exposed tank side with rough texture):

Here and on the tank shield itself I used adhesive backed heatshield material: Amazon.com: Second Skin Thermal Block - Automotive Heat Shield - Reflective Aluminum, Insulation & Adhesive (8 sq ft, 4 Sheets) - Made in USA: Automotive - https://amzn.to/3juiU2t This stuff blocks the radiant heat with the silver metal barrier but also insulates with a cloth layer underneath and sticks with adhesive which makes it easy to put anywhere. I use this small roller to help get a good bond: Amazon.com: LUMITECO Automotive Car Audio Sound Deadening Application Wheel Roller, Heat Abatement Mat Wallpaper Application PU Smoothing Tool Seam Roller: Automotive

I did the whole side of the fuel tank. I also extended the factory heatshield in a few more places:

Lastly, I used some embossed heatshield material to shield the front crossover y-pipe from the front of the fuel tank: Amazon.com: Design Engineering 050503-16 Floor and Tunnel Shield: Automotive This stuff is really lightweight and easy to bend and and cut and work with but also extremely effective at blocking radiant heat.

#2: Moving return fuel line off the engine to the firewall. This just eliminated the steel return fuel line that is bolted directly to the engine cylinder heads on the rear of the engine reducing the amount of heat returned to the tank from the fuel rails. I also covered the fuel line as well as the rest of the lines with heatshield: Amazon.com: Design Engineering 010448 Cool-Tube Extreme Heat Reflective Sleeve, 0.75" x 9' - Black: Automotive - https://amzn.to/2ZZs0ds

#3: Catalytic converter and fuel line shielding: These were the first mods I did to try and combat fuel temperature, but I would only rate them #3 on my list. Every other mod was more effective at lowering the fuel temperature. I have no doubt this mod is effective in some way, but not as much as the others. If doing heatshielding under the vehicle, then this should be done no matter what anyway IMO. It's also the easiest of all the mods. I used this heatshield for the fuel lines: Amazon.com: DEI 010441 Cool-Tube Extreme Heat Reflective Sleeve, 0.5" x 9' - Silver: Automotive - https://amzn.to/2WYqZjS

#4: Passive dual-pass finned fuel cooler. More of an experiment than anything I bought this inexpensive multipurpose cooler and plumbed it to the return line right before the fuel tank. I used quick connect fuel connectors so that if there is ever a problem with the cooler I can simply disconnect it and return the lines to stock without any tools. I placed it in the rear area above the frame rail. This area is always cool to the touch compared to the rest of the vehicle when I have been poking and probing for the last few weeks, it gets a surprising amount of air flow.

First I set it up to pressure test:

It passed.

I

Looking inside:

Mounted above the frame rail by the evap canister away from danger.

I used this 12" fuel cooler: Amazon.com: HotRod99 12" Satin Aluminum Finned Dual Pass Heat Sink Cooler Transmission Cooler Black Includes Two 1/4 NPT Fittings: Home & Kitchen - https://amzn.to/2WYwxe4

Some 5/16 Gates fuel hose: Amazon.com - https://amzn.to/302b4D9

and 1/4 NPT to 5/16 fittings: Amazon.com - https://amzn.to/3044yMe

Before doing these mods my fuel temperature would routinely get to be 30-40F higher than ambient and sometimes even 50F or more if the tank was low and/or it had been hours on the trail etc. After doing these mods the fuel now stays between 10-20F above ambient even when low, though I have not done a long offroad trip with the newest mods.

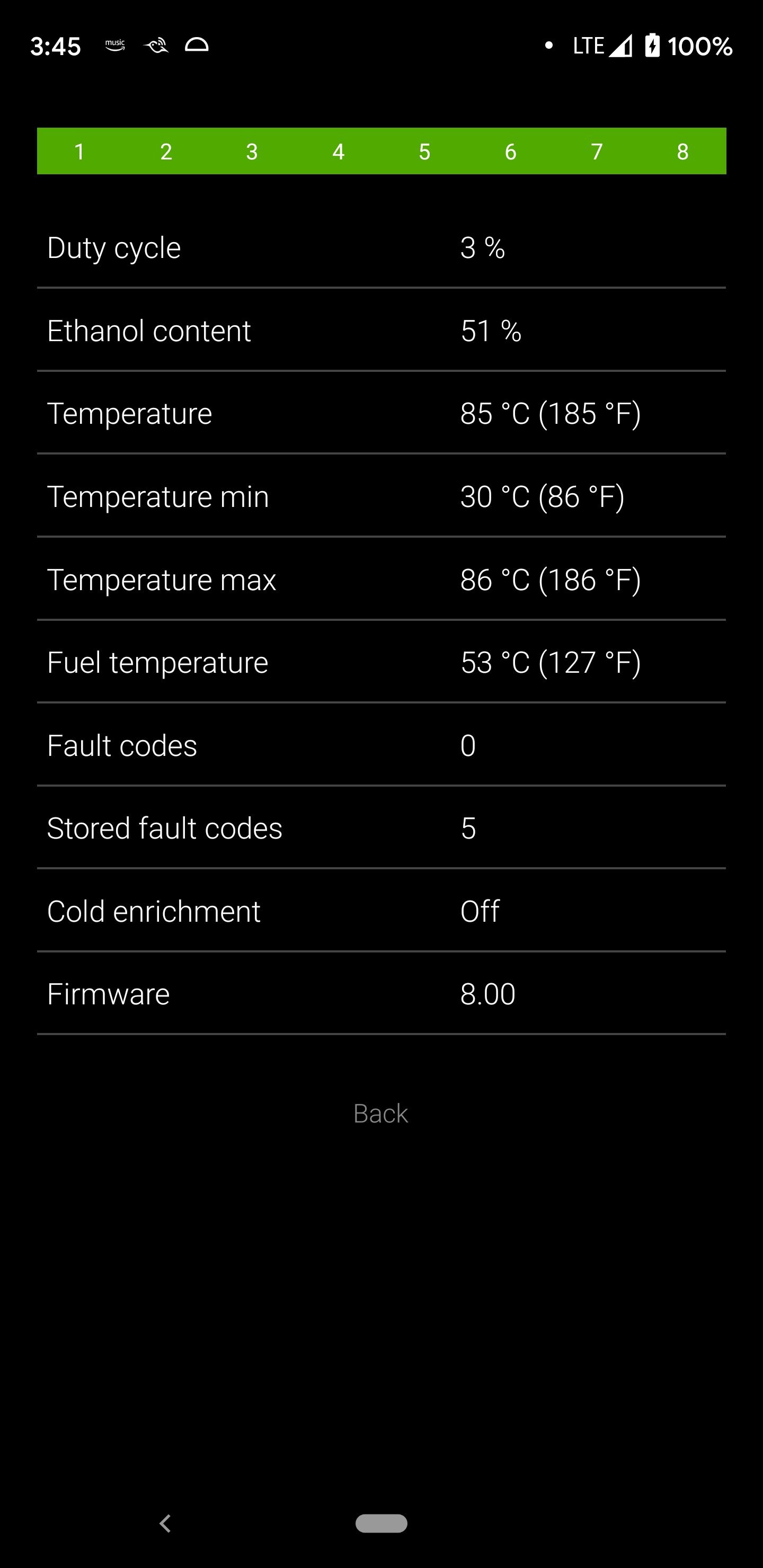

This is about the hottest fuel temp I've recorded to date (127F), though I would bet it gets even hotter. This was before mods. This was at 1/4 tank of fuel driving home in 95F ambient temperature probably 3-4 hours running non-stop. I'm waiting for similar conditions to record a snapshot of the temperature now after all of the mods.

This is not an all or nothing, with each added mitigation potentially buying more margin to managing fuel venting/boiling. It's fully possible the issue can't be fully solved but added margin is worth the effort IMO.

1. Fuel tank shielding

a. Aux tank shielding

2. Fuel line shielding around exhaust

3. Fuel line shielding around engine

4. Fuel cooler

Insulation Products

Amazon product ASIN B000CEM3O0

Need 3/8 and 5/8" wraps

Amazon product ASIN B079S1XLM7

Last edited: