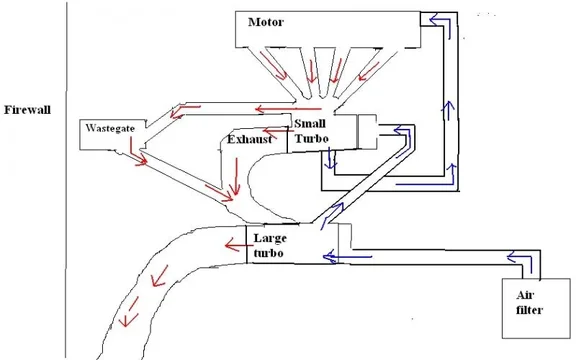

Here is how i was going to fab up my next manifold. It has several bennifits:

easier to weld up

can utilize divided manifold on large turbo making it more effecient and spool faster

turbos can be changed out easily for different ones (less welding)

Drawbacks:

will add turbo lagg on small turbo during normal accelleration. during towing or really slow accellerations the small turbo will still spool at low rpms. Its boost will just be delayed.

Because the flex pipes are downstream of both of the turbos the fabing is much much easier and dosent have to be as exact. I would recomend this way (in the pic). I did it with the small turbo first and getting it to fit properly was very tedious. I 'll draw a pic later for you on how mine is currently.

View attachment 657746

That is essentially the setup Borg Warner are running with some production diesels. The advantage is your small turbo can be smaller than it could be as a single, the disadvantage is you need more valves and more control over the system.

Depending on the sizing, you may need a bypass around the compressor of the little turbo. A spring-loaded valve so if boost gets higher from the big turbo than the little, that it can bypass the smaller compressor and head straight to the intake.

Again depending on the sizing, you might need to get clever on a bypass for the small turbine. It's the switching of this bypass that normally needs computer control to avoid a valley of death.