Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Compound turbo 3B

- Thread starter cody c

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?Those little gauges are sweet, they look really clean and are better priced comparing to the isspros I bought. This will be a really cool install Cody. I don't think you'll have a problem selling a cummins 80. Get a little tdi for your town s*** and drive your lux for more fun?

- Thread starter

- #63

That is so neat. I like the one that goes to 80lbs and the idea of measuring drive pressures and boost on the same gauge. I think ill have to upgrade.

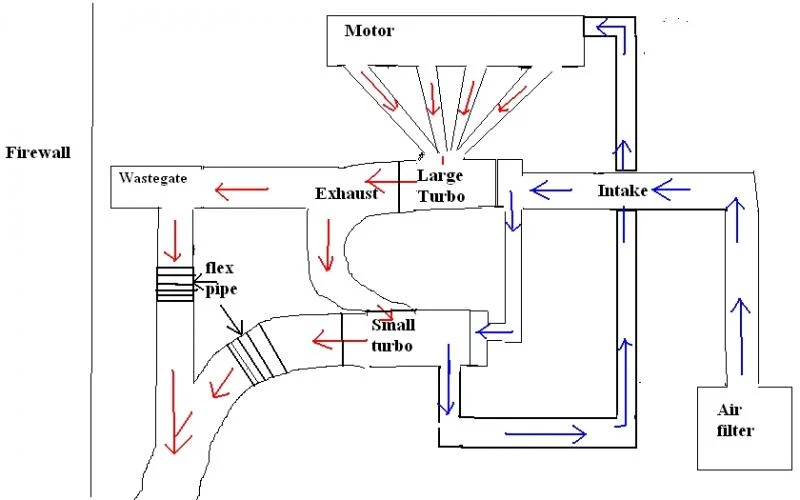

yes the large turbo boost feeds into the small one as Im not sure how it would work the other way around. I think the little turbo would overspool like crazy.

crap, now you got me second guessing if the little turbo should feed the big one or the big should feed the little.

It should be easier to blow air past the little one once its compressed from the bigger, maybe it would be less restrictive at top end this was?

Great find. Do you know what size those gauges are?

Not sure what size the gauges are, Id have to look at that site again and give them a call, Im on the fence as to what my boost range should be.

edit: the first site the phone line doesnt work, from the second I got this email in response:

"They are std 2” gauges.

Pics show colors and psi ranges. There is a 5o psi unit available also."

So, no white gauge faces, just standard black, but the 50 PSI model may be better than the 80 PSI

Those little gauges are sweet, they look really clean and are better priced comparing to the isspros I bought. This will be a really cool install Cody. I don't think you'll have a problem selling a cummins 80. Get a little tdi for your town s*** and drive your lux for more fun?

One of the guys I work with has a VW TDI, man I hate him for the mileage he gets with that thing. I would sell my 80 if someone wanted it, but I dont think its worth the money, Id want for it, so I think it may be a hard sell.

Last edited:

OK so my last post was not as clear as id like it to be. You can change up the exhaust side either way and design wastegates as needed.

The compressor side has to be air filter... large turbo... small turbo then intake. It would be extremely hard to design a functional system that does it any other way.

The compressor side has to be air filter... large turbo... small turbo then intake. It would be extremely hard to design a functional system that does it any other way.

- Thread starter

- #65

OK so my last post was not as clear as id like it to be. You can change up the exhaust side either way and design wastegates as needed.

The compressor side has to be air filter... large turbo... small turbo then intake. It would be extremely hard to design a functional system that does it any other way.

Oh, I was thinking intake should be that way. Brain sharted!

Ill stick to the plan, though I was thinking: air filter-large-small-IC-intake manifold, but that really shouldn't matter too much to run the big turbo upstream of the smaller one, Id just prefer not to build the exhaust system more than once.

I already have a pyro and oil for it, though the pyro is a white face gauge I think and the dual needle boost doesnt have that option, as well.

Last edited:

Ok so to break it downa little here. Little turbo compresses air and is mapped to a 3.4L motor for the rpm range you want and boost you want. That is all fine.

Now large turbo is much different. It is mapped to flow cfm and presure according to what the little tubo ingests. Now that is much more air than the 3.4L motor inhales. it, depending on the small turbos boost, can look like a 4.2L to 4.8L motor. So small turbo is running say 200cfm say at 3000rpm with 15lbs boost. It is actually ingesting say 340 cfm. So lare turbo compressor has to be matched for that cfm which I find is easier to convert the cfm to engine size for mapping.

Now if you have little turbo boost into the large turbo, the small compressor now has to push enough air to feed the intake of the large turbo. Now that could look like say 420 cfm... way way more then its compressor is designed for. Conversly, large turbo compressor now is running into a smaller motor and would also be out of its effeciency range, just on the surge side of the map.

does that make sence?

g

Now large turbo is much different. It is mapped to flow cfm and presure according to what the little tubo ingests. Now that is much more air than the 3.4L motor inhales. it, depending on the small turbos boost, can look like a 4.2L to 4.8L motor. So small turbo is running say 200cfm say at 3000rpm with 15lbs boost. It is actually ingesting say 340 cfm. So lare turbo compressor has to be matched for that cfm which I find is easier to convert the cfm to engine size for mapping.

Now if you have little turbo boost into the large turbo, the small compressor now has to push enough air to feed the intake of the large turbo. Now that could look like say 420 cfm... way way more then its compressor is designed for. Conversly, large turbo compressor now is running into a smaller motor and would also be out of its effeciency range, just on the surge side of the map.

does that make sence?

g

- Thread starter

- #67

Ok so to break it downa little here. Little turbo compresses air and is mapped to a 3.4L motor for the rpm range you want and boost you want. That is all fine.

Now large turbo is much different. It is mapped to flow cfm and presure according to what the little tubo ingests. Now that is much more air than the 3.4L motor inhales. it, depending on the small turbos boost, can look like a 4.2L to 4.8L motor. So small turbo is running say 200cfm say at 3000rpm with 15lbs boost. It is actually ingesting say 340 cfm. So lare turbo compressor has to be matched for that cfm which I find is easier to convert the cfm to engine size for mapping.

Now if you have little turbo boost into the large turbo, the small compressor now has to push enough air to feed the intake of the large turbo. Now that could look like say 420 cfm... way way more then its compressor is designed for. Conversly, large turbo compressor now is running into a smaller motor and would also be out of its effeciency range, just on the surge side of the map.

does that make sence?

g

Ya, more or less.

Though I could see some benefits as to how either way could work, however Im not too hung up on the logistics, you fella's have identified the components and what order to assemble them, the physics of why they work best in this order i can pick up slowly along they way.

So, this saturday I hope to start looking at the engine and the engine compartment. I should be able to finish the rear leafs maybe this evening and then my focus shifts to the front of her.

I will likely have to remove more parts from the firewall and fenders, and maybe remove more of the dashboard for the left hand swap, so getting engine mounts burnt in this weekend is quite unlikely (especially considering the pace ive set so far, and the fact that Im "solo parenting" one day on the weekends).

Last edited:

Tapage

Club 4X4 Panamá

just for reference I know for sure the new WV pickup Amarok came with 2 stage turbo setup would be interesting know more about that turbo setup .. which works quite good for HW .. but it's complete POS in the low end range ..

sorry for the small hijack ..

sorry for the small hijack ..

- Thread starter

- #69

just for reference I know for sure the new WV pickup Amarok came with 2 stage turbo setup would be interesting know more about that turbo setup .. which works quite good for HW .. but it's complete POS in the low end range ..

sorry for the small hijack ..

Way to wreck the thread Tapage ;p

That thing looks very... Aluminum.

Interesting on how they have the turbos so far forward though, never thought about that layout.

Tapage

Club 4X4 Panamá

Way to wreck the thread Tapage ;p

please my apologizes .. I will open new thread to talk about this ..

Hi jack over ..

Hey that engine looks kewl. The only thing it need is a few more belts and it perfect. By all means Tap post some stuff up. He was just bugging you. Alot can be learned by observing other compound designs. With the new vnt technology im not sure why a stock car would come with a compound set up unless it was pushing a ton of boost, or wanted to run low boost off each turbo and really tweak the back pressure. Of course a vnt compound set up would be nice. However, those controllers are pesky.

g

g

- Thread starter

- #72

please my apologizes .. I will open new thread to talk about this ..

Hi jack over ..

no, I was just joking, post away.

The routing for the exhaust will likely be a bit tight, so seeing other compound layouts would be insightful.

Tapage

Club 4X4 Panamá

I did not have the oportunity to take apart none of those engines or even take a boost pyro readings .. but had chance to drive 'em and they are weak .. I mean real weal in the low end department ..

but it's more than engine issue .. with 6 speed manual, the 1st and reverse are just way to tall .. ( lower gearing number ) that you are always relying in your clutch ..

Over 1400 rpm the story change quickly .. with great speed and towing capacity .. ( are not any closer to any 4BT cummins ) keeping in mind are just 2.0 TDI diesel ..

Believe even with a ECU controlled VNT turbo you have limits .. and this engines relys 100% on turbos works ..

but it's more than engine issue .. with 6 speed manual, the 1st and reverse are just way to tall .. ( lower gearing number ) that you are always relying in your clutch ..

Over 1400 rpm the story change quickly .. with great speed and towing capacity .. ( are not any closer to any 4BT cummins ) keeping in mind are just 2.0 TDI diesel ..

Believe even with a ECU controlled VNT turbo you have limits .. and this engines relys 100% on turbos works ..

- Thread starter

- #75

I did not have the oportunity to take apart none of those engines or even take a boost pyro readings .. but had chance to drive 'em and they are weak .. I mean real weal in the low end department ..

but it's more than engine issue .. with 6 speed manual, the 1st and reverse are just way to tall .. ( lower gearing number ) that you are always relying in your clutch ..

Over 1400 rpm the story change quickly .. with great speed and towing capacity .. ( are not any closer to any 4BT cummins ) keeping in mind are just 2.0 TDI diesel ..

Believe even with a ECU controlled VNT turbo you have limits .. and this engines relys 100% on turbos works ..

With all the belts on that thing I hope its a non interference engine.

- Thread starter

- #76

Well, nothing has really happened on the hilux since november.

Man, Ive caught like every cold or flu going around, Im sick this week, had four days between the last two week cold, and my wife has been working both days of the weekends which means "daddy day care" for me on the weekends. It seems if I have ten minutes to work in the garage Im too worn out to get out there,

Enough whining for ya!

I did order a complete set of flanges for the turbo`s and intake flanges where it has a flange instead of a pipe outlet. I will pick them up this weekend at MSO (Montana shipping outlet) and maybe order the elbows and tee`s to make the exhaust manifold this week.

The firewall needs to be swapped from a domestic before I start fitting the engine, and getting down to pick'n pull in the cold weather we've had with the lack of free time I've had to sawzall out a firewall and disassemble the interior of a mini truck has been a bit easy to procrastinate.

A friend said he would help with the firewall at some point and I marked it in the calendar so the better half can give me a saturday off to get it done though, so it will eventually happen.

So enough yabbering, here's my question,

Ive been on and off about mounting the exhaust compressor of the bigger turbo closest to the manifold.

I can see how having the exhaust feed through the little turbo and a wastegate could rob pressure and heat to supply the bigger turbo (if the smaller turbo was mounted first).

But if there is clearance issues to mounting bigger turbo first, does it make alot of difference if mounted either way?

Man, Ive caught like every cold or flu going around, Im sick this week, had four days between the last two week cold, and my wife has been working both days of the weekends which means "daddy day care" for me on the weekends. It seems if I have ten minutes to work in the garage Im too worn out to get out there,

Enough whining for ya!

I did order a complete set of flanges for the turbo`s and intake flanges where it has a flange instead of a pipe outlet. I will pick them up this weekend at MSO (Montana shipping outlet) and maybe order the elbows and tee`s to make the exhaust manifold this week.

The firewall needs to be swapped from a domestic before I start fitting the engine, and getting down to pick'n pull in the cold weather we've had with the lack of free time I've had to sawzall out a firewall and disassemble the interior of a mini truck has been a bit easy to procrastinate.

A friend said he would help with the firewall at some point and I marked it in the calendar so the better half can give me a saturday off to get it done though, so it will eventually happen.

So enough yabbering, here's my question,

Ive been on and off about mounting the exhaust compressor of the bigger turbo closest to the manifold.

I can see how having the exhaust feed through the little turbo and a wastegate could rob pressure and heat to supply the bigger turbo (if the smaller turbo was mounted first).

But if there is clearance issues to mounting bigger turbo first, does it make alot of difference if mounted either way?

I have pondered this for my next compound build and, from my expereince with my first build, I will mount the large turbo first to the exhaust manifold. No matter which way you go you need exhaust to go through small turbo and a wastegate, but welding with large turbo first is much easier and allows for the piping to include flex pipe where as small turbo first doesnt. It also makes it much much easier to change out small and large turbo if you want to put something different on.

Now compressor side stays the same: filter - large turbo - small turbo - intake manifold

The only down side to large first is slight lag on small turbo as there is more volume to pressurize before the exhaust reaches it.

Another bennifit is that during peak boost large turbo will recieve the hottest fastest gasses allowing to to run more effeciently.

Now compressor side stays the same: filter - large turbo - small turbo - intake manifold

The only down side to large first is slight lag on small turbo as there is more volume to pressurize before the exhaust reaches it.

Another bennifit is that during peak boost large turbo will recieve the hottest fastest gasses allowing to to run more effeciently.

Greg, in a set-up like you have posted here would you need the have a wategate to bypass the small turbo's turbine wheel? Or does the hot pipe mounted wastegate remove the need? Having the larger turbo mounted on the manifold and feed the smaller one would work much better with the space constraints I have.

What is keeping the big turbo's boost under control?

Could maybe make the TD04HL-13T work as a small turbo and run something like a TD05 or 6-20G as the big?

What is keeping the big turbo's boost under control?

Could maybe make the TD04HL-13T work as a small turbo and run something like a TD05 or 6-20G as the big?

I have pondered this for my next compound build and, from my expereince with my first build, I will mount the large turbo first to the exhaust manifold. No matter which way you go you need exhaust to go through small turbo and a wastegate, but welding with large turbo first is much easier and allows for the piping to include flex pipe where as small turbo first doesnt. It also makes it much much easier to change out small and large turbo if you want to put something different on.

Now compressor side stays the same: filter - large turbo - small turbo - intake manifold

The only down side to large first is slight lag on small turbo as there is more volume to pressurize before the exhaust reaches it.

Another bennifit is that during peak boost large turbo will recieve the hottest fastest gasses allowing to to run more effeciently.

Your boost control also becomes a little more complex. The factory systems which run like this have the benefit of computer controlled bypass/switchover valves.

Running the normal compound setup is more naturally self-regulating.

Greg, in a set-up like you have posted here would you need the have a wategate to bypass the small turbo's turbine wheel? Or does the hot pipe mounted wastegate remove the need? Having the larger turbo mounted on the manifold and feed the smaller one would work much better with the space constraints I have.

What is keeping the big turbo's boost under control?

Could maybe make the TD04HL-13T work as a small turbo and run something like a TD05 or 6-20G as the big?

The small turbo in a normal compound setup is processing the same volume it does as a single, so the compressor and turbine remain sized pretty similar to one that normally runs at that pressure ratio. The equivalent of a single providing 10psi (PR 1.7) gets quite good when it's also fed a PR of 1.7 by a bigger turbo (total PR 2.9 = 28psi).

What does change is the density the little turbo is pumping. If it's pumping air at 1.5 times the density, then shaft torque is 50% higher. You don't want to pick a fragile turbo.

If your little turbo is running a density ratio of 1.5, then your big turbo needs to be 50% bigger air-flow wise. You can likely go bigger still to offset the operating curves rather than making them both peak at the same point.

But doing it the way Gerg has shown in that diagram, you can make the turbine on the small one very small. It no longer has to process the full flow of the engine. The compressor however still does. So you'll have to start combining turbo parts.

The wastegate from the big turbo bypassing the little is your overall boost control.

Similar threads

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)