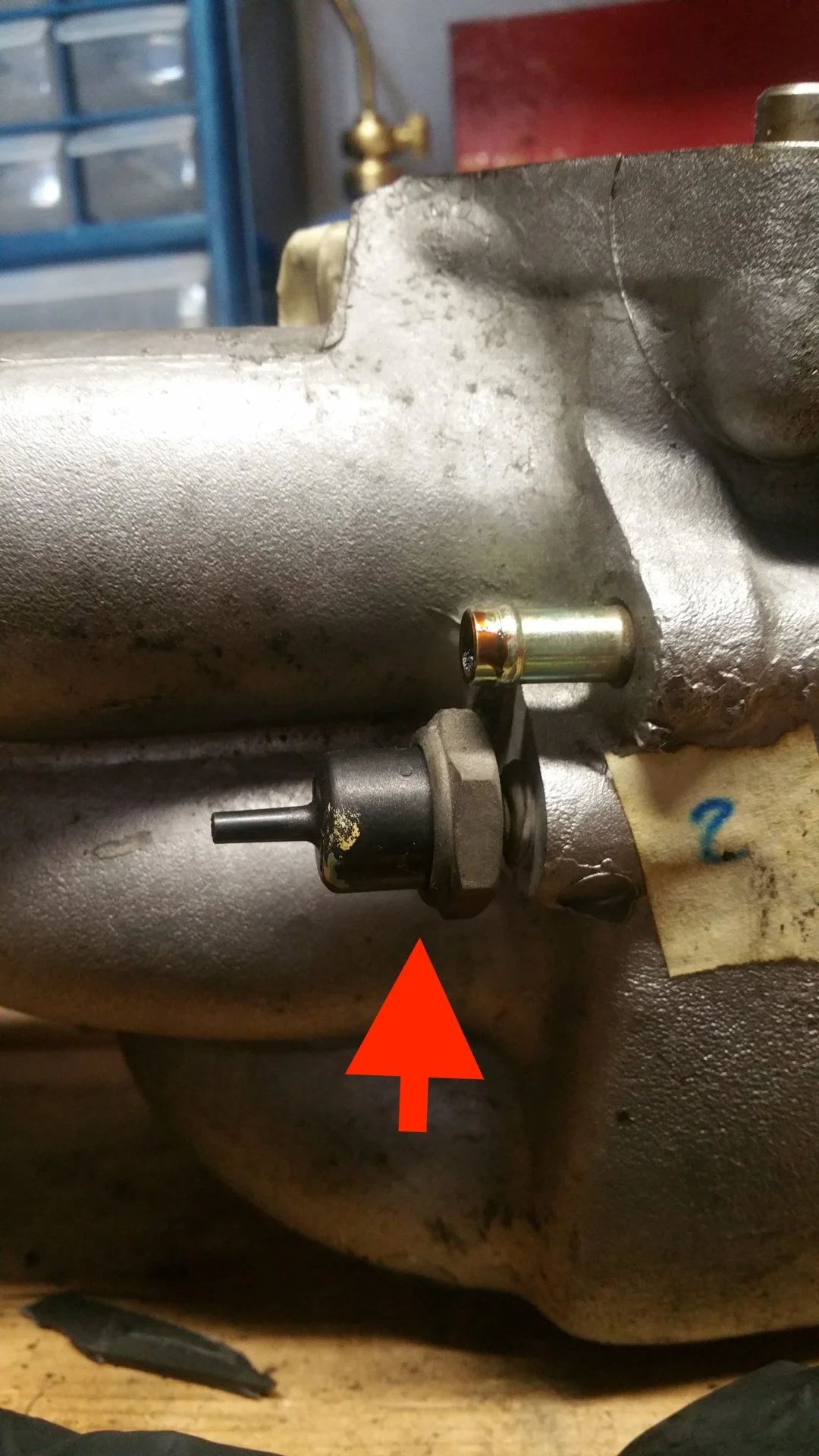

Hey all, I pulled the upper intake to check on the EGR valve intake and check vacuum lines (baselining a new truck, also failed emissions with high NoX a few weeks ago.) I'm not opposed to having it sit in a bucket of simple green overnight, but I wasnt sure if I should remove the last plastic component on the intake. I think it's called the vacuum filter? Anyway, I dont know how hard they are to get off. It looks like it has some kind of sealant at the threads. What do people normally do with this thing? I've looked around the forum a bunch but couldnt find any answers. Thanks!

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cleaning upper intake

- Thread starter JustAnotherDave

- Start date

-

- Tags

- fzj80 intake manifold

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?Just unbolt it. No reason to risk soaking it.

inkpot

SILVER Star

It’s a 24 mm to unscrew it. I cleaned mine with carb cleaner. I put some Teflon tape on the threads and screwed it back in.

- Thread starter

- #4

Thanks for the advice!

Popular little part these days....

Anyone know the torque value? I couldn't find it in my PDF FSM.

Anyone know the torque value? I couldn't find it in my PDF FSM.

when I pilled mine out it looked like a tapered thread so I just went till it was tight with a little tefelon tape on the threads, so far so good

inkpot

SILVER Star

A little more than finger tight should work. It doesn't need to be very tight with a 24 mm wrench or you will mess it up.

Malleus

Far west of Siegen

I've looked for this part in every one of mine and it's not there. If someone finds it, please let me know. Most of the thread torque specifications for "X" to Air Intake Chamber are 13-14-lb·ft, FWIW.Anyone know the torque value? I couldn't find it in my PDF FSM.

Here's where I go when I don't know something:

Pipe Thread Installation Torque Table Chart | Engineers Edge | www.engineersedge.com

If you assume the Gas filter thread is about 1/4NPT, the torque value of 16-lb·ft is about right.

inkpot

SILVER Star

I’m not gunna get out my thread pitch gauge and pull that rascal back off of the intake, but I thought the thread depth on that filter was less than that of standard pipe. With a little Teflon tape on it, it won’t take much torque to seal it and secure it from backing out. No rocket science required?

Malleus

Far west of Siegen

For sure. It can't be standard pipe, because the Japanese don't use it. I don't have a reference for Japanese metric, parallel or tapered pipe threads (I gave up long ago when trying to plug my 40's smog manifold), so I posted this as a rule of thumb reference. Unlike most things on this truck, I don't think the torque here (beyond tight) matters much. Tapered threads are pretty good about sealing.

I cleaned mine just for fun. It passed air just fine, though one side was maybe a little bit restricted. I sprayed some carb cleaner through until it came out clean and put it back in.

When I removed it, the threads were coated with that gray sealant that stays pliable.

When I removed it, the threads were coated with that gray sealant that stays pliable.

I cleaned mine just for fun. It passed air just fine, though one side was maybe a little bit restricted. I sprayed some carb cleaner through until it came out clean and put it back in.

When I removed it, the threads were coated with that gray sealant that stays pliable.

was there anything wrong before you cleaned it, and was there anything better after?

was there anything wrong before you cleaned it, and was there anything better after?

Nah, I'd already cleaned the intake as thoroughly as possible with it in-place, and my engine's been running great for the better part of a year now. I'd always wondered about that splitter/filter thing, though, so I figured why not.

Similar threads

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)