Looks like you need to attack those connections with some electrical shrink wrap once it is all in place!

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Builds Boo471 Build (1 Viewer)

- Thread starter boo471

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?- Thread starter

- #42

Looks like you need to attack those connections with some electrical shrink wrap once it is all in place!

Yep you are probably right. Just sooooo darn slow to shrink wrap

Awesome job on the switch install. Interested in how you cut your holes for the switches. A lot of people butcher their panels when cutting the holes and all the switches are out of alignment.

Next time you have the panel off, an easy fix and piece of mind for the switch connections making contact with metal or other wires, is to put some heat shrink over the spade connectors. A lot cheaper than buying the covered marine spade connectors.

Keep up the good work!

Next time you have the panel off, an easy fix and piece of mind for the switch connections making contact with metal or other wires, is to put some heat shrink over the spade connectors. A lot cheaper than buying the covered marine spade connectors.

Keep up the good work!

^^^^beat me to it.

- Thread starter

- #45

Thanks!

So I did all the wiring today as well. There was a lot of wiring to hook up 6 of these switches. 2 of them (LED light bar and Spot lights) should only be triggered if the headlights where on. 3 of them (reverese lights, fog lights and winch) only triggered when ignition was on on and 1 of them (AUX Battery) working when ever.

All the load wires are plugged up to terminals waiting to be hooked up to relays. I'll wait to plug does in untill I get my lights/parts.

I did all the wiring. Tested and measured everything. The whole thing worked fine. I put all the panels back and went back to try everything one last time.

Some of them worked fine but LED only worked if Winch and AUX was active. AUX was on constantly when the headlights where on. So something got squeezed when I put the panel back. Oh well, Its only a few panels and "5 screws positioned by the devil" (they are impossible to get to) to remove the panel again.

I dont think I'll burn the car down so I'll do that tomorrow.

Here is what it looks like.

A few wires....

LEDs are controlled by the dash light. None of the switches active.

All switches active.

Ok there was nothing wrong with the connections under the panel. Apperently i must have gotten a brain freeze. I know I should have used shrink wrap. God knows I have a box full of it. Just so darn boring.

When i pulled all the wiring thru the firewall in the begining of the day I marked both ends of each wire. These where all there when I did my first systems test. When everything was assemblied I had dropped 3 of my markings in the engine room side of the wires. And I did a messy job checking which was which and that's what caused my confusion. Probably the lack of beer that caused it.

Awesome job on the switch install. Interested in how you cut your holes for the switches. A lot of people butcher their panels when cutting the holes and all the switches are out of alignment.

Next time you have the panel off, an easy fix and piece of mind for the switch connections making contact with metal or other wires, is to put some heat shrink over the spade connectors. A lot cheaper than buying the covered marine spade connectors.

Keep up the good work!

Thanks! What I do that will give you a pretty good result. I create a paper template for the layout. Both inner dimensions and outer dimensions (including space inbetween the switches). See picture, note that i made up for my lack of beer earlier in the day.

[URL="http://i1293.photobucket.com/albums/b585/Marten_Medin/mall_zpseeea25de.jpeg"]

[/URL]

[/URL]Tejp template to panel and mark the holes with a marker. Use a dremel with a cutting wheel and cut along the marked line. There is no need to cut thru the entire panel. You just cut thru the top surface/lacker to get a clean cut and so it wont melt the lacker later on and mess up your panel. Be carefull so your dremel wont jump around and scratch the panel. Once you cut the outer lines on all holes. Use a drill and drill a hole in the center of where the switch should go. Then use a cone shaped grinder for your dremel and push it down in the drilled hole and move it around slowly untill you got your entire opening. Make sure the panel dont get to hot if you have wood with lacker since it can start to come loose from your panel (cutting before grinding helps but does not make it bomb proof).

Good luck!

//Marten

Really? Noone else is going to ask?

Ok, what's the zombie targeting system about?

Ok, what's the zombie targeting system about?

- Thread starter

- #47

Lights....

Hehe these are my Zombie targeting system. I wonder if they are big enough

[URL=http://s1293.photobucket.com/user/Marten_Medin/media/image_zps3f8dc5a8.jpeg.html] [/URL]

[/URL]

My plan was to get 2x7" mounted in the grill and 4x5" on the roof. But found a decent LED bar at a good price so decided to use that on the roof and got 2x9" mounted in the grill for distance instead.

[URL=http://s1293.photobucket.com/user/Marten_Medin/media/bild2_zps73ada67c.jpeg.html] [/URL]

[/URL]

[URL=http://s1293.photobucket.com/user/Marten_Medin/media/bild3_zpsdc41ed01.jpeg.html] [/URL]

[/URL]

The LED light bar had some scuff marks on it. Shipped from China in a half decent package. But other then that it seems to be of really good quality and not far behind more commonly used brands. I guess most of them are produced with similar parts in similar factories in China and just branded differently like everything else. We'll see how long they hold up, they where all dirt cheap so I wont cry blood when I crack a lens agains a branch.

But other then that it seems to be of really good quality and not far behind more commonly used brands. I guess most of them are produced with similar parts in similar factories in China and just branded differently like everything else. We'll see how long they hold up, they where all dirt cheap so I wont cry blood when I crack a lens agains a branch.

///Marten

Really? Noone else is going to ask?

Ok, what's the zombie targeting system about?

Hehe these are my Zombie targeting system. I wonder if they are big enough

[URL=http://s1293.photobucket.com/user/Marten_Medin/media/image_zps3f8dc5a8.jpeg.html]

[/URL]

[/URL]My plan was to get 2x7" mounted in the grill and 4x5" on the roof. But found a decent LED bar at a good price so decided to use that on the roof and got 2x9" mounted in the grill for distance instead.

[URL=http://s1293.photobucket.com/user/Marten_Medin/media/bild2_zps73ada67c.jpeg.html]

[/URL]

[/URL][URL=http://s1293.photobucket.com/user/Marten_Medin/media/bild3_zpsdc41ed01.jpeg.html]

[/URL]

[/URL]The LED light bar had some scuff marks on it. Shipped from China in a half decent package.

But other then that it seems to be of really good quality and not far behind more commonly used brands. I guess most of them are produced with similar parts in similar factories in China and just branded differently like everything else. We'll see how long they hold up, they where all dirt cheap so I wont cry blood when I crack a lens agains a branch.

But other then that it seems to be of really good quality and not far behind more commonly used brands. I guess most of them are produced with similar parts in similar factories in China and just branded differently like everything else. We'll see how long they hold up, they where all dirt cheap so I wont cry blood when I crack a lens agains a branch. ///Marten

SouthernSS

Owner of Southern Style Speed

- Joined

- Jul 3, 2012

- Threads

- 8

- Messages

- 640

- Location

- Baton Rouge, LA

- Website

- www.southernstylespeed.com

We had one of those LED bars from china. It worked just fine till we took a rock right through the lens on the way up to the ORV park. Heck, it still works, but the lens is cracked and its gathering moisture inside. But like you said, its cheap enough not to cry about it when it does break.

- Thread starter

- #50

SouthernSS

Owner of Southern Style Speed

- Joined

- Jul 3, 2012

- Threads

- 8

- Messages

- 640

- Location

- Baton Rouge, LA

- Website

- www.southernstylespeed.com

i love getting new material!!

- Thread starter

- #52

i love getting new material!!

Like Christmas Day!

- Thread starter

- #53

Electrical wiring issue.

Howdy,

So I got my steel yesterday. I started building the roof rack frame. Tried out my new welder for the first time and also tested my welding skills for the first time in 8 years. It was a lot smoother than I expected. Just using flux at the moment but the welds seems to get pretty decent even without gas.

I'll post some pictures during the weekend probably when I have gotten some more work done.

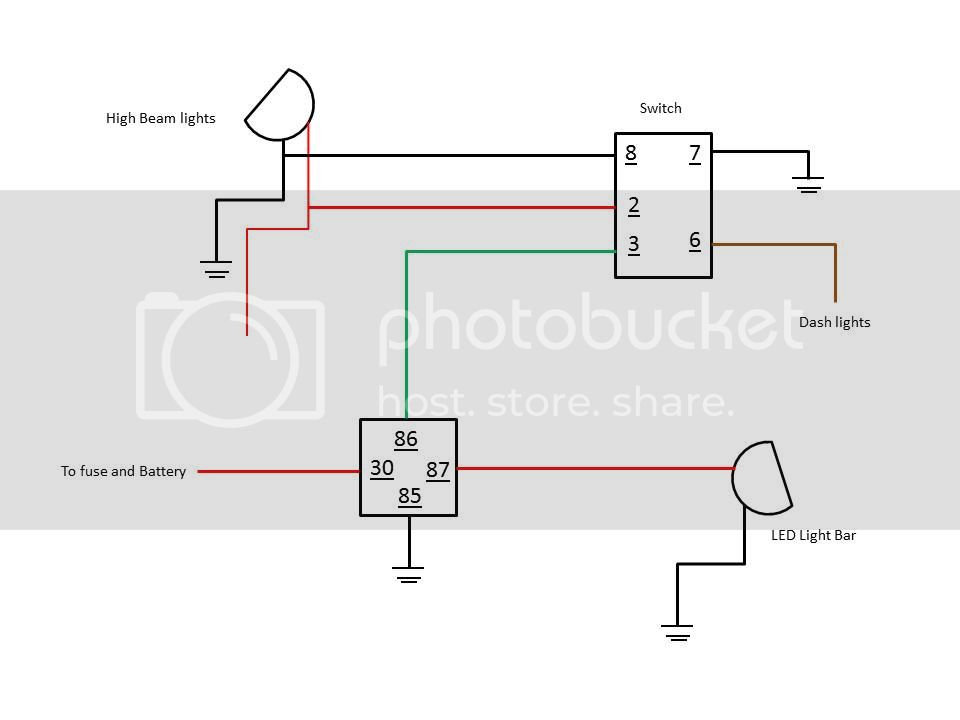

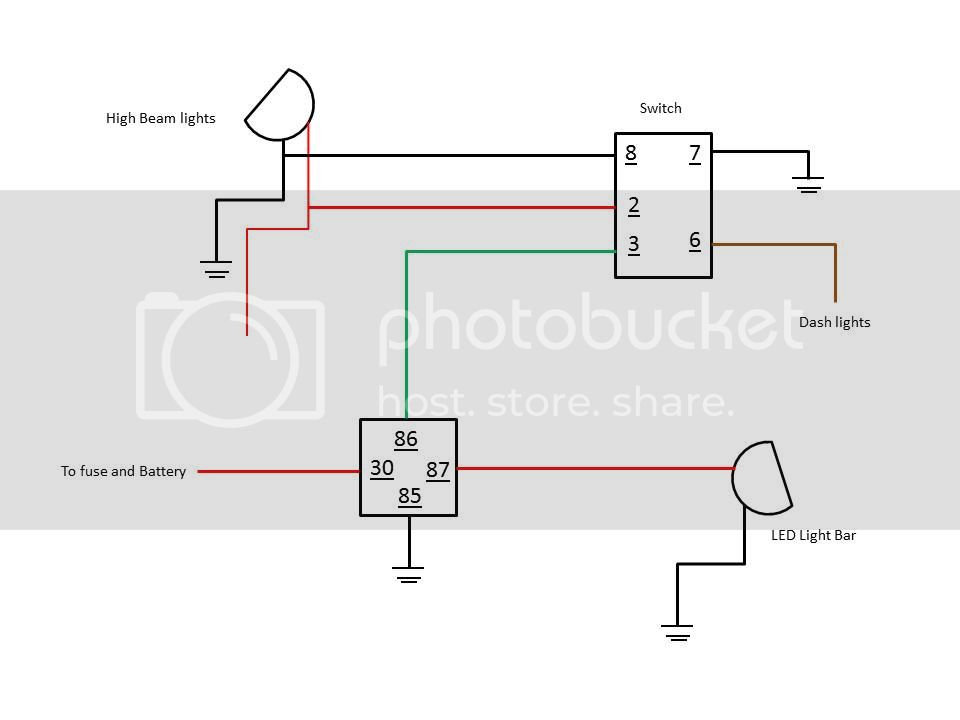

Anyways, I have an issue with my wiring for my LED light bar and my Spot lights. What I want to do is to use my toggle switches to active the circuits for them but use my high beam to control them. Meaning I want them to be able (controlled by rocker switch) to be ON when the high beam is ON and I them to be OFF when high beam is OFF.

I know the Lexus has a switched ground situation going on (new to me). So what I did was. I measured the high beam circuit, positive and ground cable and it has 0V until you turn them on then the circuit gets activated. So I plugged in my switch to the high beam circuit. Switch incoming trigger to high beam positive and switch ground to high beam ground. So now when I test the switch, sure enough it will only activate (upper LED light on switch turns on) when high beam is active. BUT the switch will send a trigger signal to the relay when either the high beam or low beam is on. Which makes no sense to me? I did a simple diagram please help out and tell me what's wrong with my set up because I’m lost here. Should I connect the ground for the Switches LED lights to the high beam ground as well?

[URL="http://i1293.photobucket.com/albums/b585/Marten_Medin/Switchdiagram_zps0b2120b3.jpg"] [/URL]

[/URL]

Thanks,

Marten

Howdy,

So I got my steel yesterday. I started building the roof rack frame. Tried out my new welder for the first time and also tested my welding skills for the first time in 8 years. It was a lot smoother than I expected. Just using flux at the moment but the welds seems to get pretty decent even without gas.

I'll post some pictures during the weekend probably when I have gotten some more work done.

Anyways, I have an issue with my wiring for my LED light bar and my Spot lights. What I want to do is to use my toggle switches to active the circuits for them but use my high beam to control them. Meaning I want them to be able (controlled by rocker switch) to be ON when the high beam is ON and I them to be OFF when high beam is OFF.

I know the Lexus has a switched ground situation going on (new to me). So what I did was. I measured the high beam circuit, positive and ground cable and it has 0V until you turn them on then the circuit gets activated. So I plugged in my switch to the high beam circuit. Switch incoming trigger to high beam positive and switch ground to high beam ground. So now when I test the switch, sure enough it will only activate (upper LED light on switch turns on) when high beam is active. BUT the switch will send a trigger signal to the relay when either the high beam or low beam is on. Which makes no sense to me? I did a simple diagram please help out and tell me what's wrong with my set up because I’m lost here. Should I connect the ground for the Switches LED lights to the high beam ground as well?

[URL="http://i1293.photobucket.com/albums/b585/Marten_Medin/Switchdiagram_zps0b2120b3.jpg"]

[/URL]

[/URL]Thanks,

Marten

Whoa... deja vu!

- Thread starter

- #55

Whoa... deja vu!

Lol ok any tips on how to solve it? I have never played around with switched ground before. To... to backwards for me.

Ya it's a pain. I've built a few headlight harnesses, so I know it is tricky.

I need to know what's going on with the switch you're using. Can you give some detail? Something like this?

Do you have the Wiring manual for your truck? Highly highly recommended if you're messing with factory wiring, sometimes it's really hard to figure out what the heck they are doing, and I've made incorrect assumptions before.

http://www.ebay.com/itm/2004-Lexus-...anuals_Literature&hash=item5d35e1c72b&vxp=mtr

I need to know what's going on with the switch you're using. Can you give some detail? Something like this?

Do you have the Wiring manual for your truck? Highly highly recommended if you're messing with factory wiring, sometimes it's really hard to figure out what the heck they are doing, and I've made incorrect assumptions before.

http://www.ebay.com/itm/2004-Lexus-...anuals_Literature&hash=item5d35e1c72b&vxp=mtr

Last edited:

- Thread starter

- #57

Ya it's a pain. I've built a few headlight harnesses, so I know it is tricky.

I need to know what's going on with the switch you're using. Can you give some detail? Something like this?

[URL="http://www.learningaboutelectronics.com/images/DPDT-toggle-switch-diagram.png"][/URL]

Do you have the Wiring manual for your truck? Highly highly recommended if you're messing with factory wiring, sometimes it's really hard to figure out what the heck they are doing, and I've made incorrect assumptions before.

http://www.ebay.com/itm/2004-Lexus-...anuals_Literature&hash=item5d35e1c72b&vxp=mtr

Its probably not that hard. Just me that needs to wrap my head around this swtiched ground thing. Yep I do have to full manual for the GX470 so I got all the wiring schematics for the car. Below is the only diagram I have for the switch and the part of the wiring diagaram on the car that might be interesting.

[URL="http://i1293.photobucket.com/albums/b585/Marten_Medin/Bild1_zpsbc810a12.jpeg"]

[/URL]

[/URL][URL="http://i1293.photobucket.com/albums/b585/Marten_Medin/bild3_zps624d1812.jpg"]

[/URL]

[/URL]- Thread starter

- #58

Roof rack build.

I got some work done on the roof rack yesterday. Like I mention in my first post. This roof rack will be built to hold my RTT and with a "basket" in front to hold either a spare tire or what ever else one would want up there. It will have mounting points for my LED light bar and for reverse/work lights in the back. I will also build a custom sliding adjuster and mount a 100W solar panel that will be horizontaly mounted above the LED light bar and that can slide forward, above the windshield when parked.

I did shorten the rack a little bit compared to my original design. It was just to big. It looked weird and I wanted to keep the weight down.. There is still enough room up there to put a whole lot of stuff.

The frame is built out of 1"x0.120 DOM tube, 1" and 3/4" HREW tube. Should be pretty sturdy once everything is welded down properly.

Right now Im debating how to design the mounting brackets on the truck. I want to make sure it's waterproof so might need to go get some more seals (for GX470s without roof rails). So no water gets in under the current seals.

Wife grinding down my not so pretty welds (its been a while since I welded).

[URL="http://i1293.photobucket.com/albums/b585/Marten_Medin/Bild2_zps49555ce8.jpeg"][URL="http://i1293.photobucket.com/albums/b585/Marten_Medin/Bild2_zps49555ce8.jpeg"][URL="http://i1293.photobucket.com/albums/b585/Marten_Medin/Bild2_zps49555ce8.jpeg"] [/URL][/URL][/URL]

[/URL][/URL][/URL]

This is how far we got yesterday before I had to stop working and start moving a Copper head snake instead that my dog was playing around with.

[URL="http://i1293.photobucket.com/albums/b585/Marten_Medin/Bild3_zpsb22b3484.jpeg"][URL="http://i1293.photobucket.com/albums/b585/Marten_Medin/Bild3_zpsb22b3484.jpeg"][URL="http://i1293.photobucket.com/albums/b585/Marten_Medin/Bild3_zpsb22b3484.jpeg"] [/URL][/URL][/URL]

[/URL][/URL][/URL]

I got some work done on the roof rack yesterday. Like I mention in my first post. This roof rack will be built to hold my RTT and with a "basket" in front to hold either a spare tire or what ever else one would want up there. It will have mounting points for my LED light bar and for reverse/work lights in the back. I will also build a custom sliding adjuster and mount a 100W solar panel that will be horizontaly mounted above the LED light bar and that can slide forward, above the windshield when parked.

I did shorten the rack a little bit compared to my original design. It was just to big. It looked weird and I wanted to keep the weight down.. There is still enough room up there to put a whole lot of stuff.

The frame is built out of 1"x0.120 DOM tube, 1" and 3/4" HREW tube. Should be pretty sturdy once everything is welded down properly.

Right now Im debating how to design the mounting brackets on the truck. I want to make sure it's waterproof so might need to go get some more seals (for GX470s without roof rails). So no water gets in under the current seals.

Wife grinding down my not so pretty welds (its been a while since I welded).

[URL="http://i1293.photobucket.com/albums/b585/Marten_Medin/Bild2_zps49555ce8.jpeg"][URL="http://i1293.photobucket.com/albums/b585/Marten_Medin/Bild2_zps49555ce8.jpeg"][URL="http://i1293.photobucket.com/albums/b585/Marten_Medin/Bild2_zps49555ce8.jpeg"]

[/URL][/URL][/URL]

[/URL][/URL][/URL]This is how far we got yesterday before I had to stop working and start moving a Copper head snake instead that my dog was playing around with.

[URL="http://i1293.photobucket.com/albums/b585/Marten_Medin/Bild3_zpsb22b3484.jpeg"][URL="http://i1293.photobucket.com/albums/b585/Marten_Medin/Bild3_zpsb22b3484.jpeg"][URL="http://i1293.photobucket.com/albums/b585/Marten_Medin/Bild3_zpsb22b3484.jpeg"]

[/URL][/URL][/URL]

[/URL][/URL][/URL]

Last edited:

Looking good. Are we going to see a finished product next Saturday?

- Thread starter

- #60

Looking good. Are we going to see a finished product next Saturday?

Thanks. We will see. It depends on the weather. If I can be outside and work. Don't like to weld in the rain

Similar threads

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)